How to Improve Productivity in Manufacturing with Smart Tech

Boosting productivity in manufacturing operations requires more than incremental improvements. Significant gains now come from a fundamental shift in how people work, a shift powered by immersive technologies like Augmented Reality (AR) and Virtual Reality (VR).

These are not futuristic concepts; they are practical tools that directly solve some of the most persistent challenges on the factory floor, from complex assembly and equipment downtime to persistent skills gaps.

The Next Leap in Manufacturing Productivity

The factory floor is in constant evolution. Staying competitive means embracing technologies that fundamentally reshape how work gets done, not just making minor efficiency adjustments. This guide cuts through the hype to demonstrate how immersive tools are delivering real-world productivity gains today.

We are focused on tangible applications that solve the problems manufacturers face every single day.

Addressing Core Manufacturing Challenges

At its core, improving productivity involves two primary goals: minimizing waste and maximizing the time your team spends adding value. For years, the focus has been on refining physical processes, but the greatest untapped potential now lies in empowering your workforce with better information, precisely when they need it.

This is the exact strength of AR and VR solutions.

Consider the most common drags on a manufacturing operation:

- Complex Assembly: Technicians rely on thick paper manuals or attempt to decipher complex 2D diagrams, a slow process that is a recipe for errors.

- Costly Equipment Downtime: A critical machine fails, and the most experienced technician is unavailable or off-site. Every minute spent waiting for an expert is a minute of lost production.

- The Ever-Present Skills Gap: Bringing new hires up to speed on intricate machinery is slow, expensive, and can introduce safety risks.

- Inefficient Quality Control: Manual inspections are tedious and prone to human error, leading to rework, scrap, and customer dissatisfaction.

Immersive tech offers a direct answer to each of these problems. By overlaying digital instructions onto a real-world view or creating a risk-free virtual training space, you can transform how employees learn, work, and solve problems on the shop floor.

A Practical Path Forward

This guide will walk you through a clear framework for pinpointing your biggest bottlenecks and matching them with the right AR or VR solution. You will see exactly how these tools can reduce errors, streamline workflows, and ultimately create a smarter, more efficient production process.

To get the full picture, it's also helpful to look at broader operational efficiency strategies. Those high-level principles work hand-in-hand with the specific technologies we're focused on here, helping you build a more complete plan for improvement.

The end goal is simple: give your team the tools they need to perform at their absolute best. For more inspiration, you can explore some of the other new technologies in manufacturing that are reshaping the entire industry. Consider this your starting point for making real, practical gains in manufacturing efficiency.

Pinpointing Your Biggest Operational Drags

Before you can solve a problem, you have to truly understand it. A common misstep is adopting new technology for an undefined issue, which is a fast track to wasted investment. To genuinely improve productivity in manufacturing, you must start by auditing your current operations to find the hidden drains on your efficiency.

This isn’t about guesswork. It’s about moving beyond surface-level assumptions and digging into the hard data that tells the real story of your factory floor. You need to create a clear, evidence-based map of your most critical weaknesses.

Moving Beyond Gut Feelings with Core KPIs

Your journey starts with tracking the right Key Performance Indicators (KPIs). These metrics are the vital signs of your plant's health; they provide objective insights into where your processes are performing well and where they are falling short. Three of the most essential KPIs for any production environment are OEE, MTTR, and FPY.

- Overall Equipment Effectiveness (OEE): This is the gold standard for measuring manufacturing productivity. It is a powerful metric because it combines three critical factors—Availability (uptime), Performance (speed), and Quality (good parts)—into a single score. It reveals the true productive capacity of your equipment. An OEE score of 85% is considered world-class, yet many facilities operate far below this mark without even realizing it.

- Mean Time to Repair (MTTR): This metric tracks the average time it takes to fix a machine after it goes down. A high MTTR is a significant red flag. It often points to deeper issues like a lack of skilled technicians, poor access to repair documentation, or difficulty diagnosing the problem.

- First Pass Yield (FPY): How many of your products are made correctly the first time, without any rework or scrap? That's what FPY measures. A low FPY indicates underlying problems in your assembly process, quality control, or employee training.

Tracking these KPIs provides a solid, data-driven foundation. It lets you replace "I think we have a problem here" with "We know this machine's downtime cost us $50,000 last quarter."

The goal isn't just to collect data, but to use it to ask better questions. A declining OEE score on a specific line should prompt you to investigate the root cause—is it frequent micro-stoppages, slow changeovers, or a spike in defective parts?

Identifying Common Manufacturing Bottlenecks

Once you have your core KPIs, you can start pinpointing specific problem areas. Bottlenecks can hide in plain sight, but they all leave a data trail. This table outlines some of the usual suspects on factory floors and how to track their impact.

| Bottleneck Area | Description | Key Metric to Track (KPI) | Potential Impact of AR/VR |

|---|---|---|---|

| Complex Assembly | Tasks requiring intricate steps, leading to high error rates and slow cycle times, especially for new hires. | First Pass Yield (FPY), Rework Rate | Guided AR instructions projected onto the workpiece, reducing cognitive load and errors. |

| Equipment Downtime | Time lost due to machine failures, often extended by slow diagnosis and repair processes. | Mean Time to Repair (MTTR), Overall Equipment Effectiveness (OEE) | AR-powered remote assistance connecting junior techs with senior experts instantly. |

| Inefficient Training | New employees take a long time to become proficient, relying heavily on senior staff for guidance. | Time to Proficiency, Training Cost per Employee | Immersive VR simulations for hands-on practice in a safe, controlled environment. |

| Quality Control | Manual inspection processes that are slow, inconsistent, and prone to human error. | Defect Rate, Scrap Rate | AR overlays that highlight acceptable tolerances and deviations directly on a physical part. |

By cross-referencing your KPI data with these common bottleneck areas, you can quickly narrow down where your biggest opportunities for improvement lie.

Uncovering the "Why" Behind the Numbers

Data tells you what is happening, but it rarely tells you why. The next crucial step is to get out on the floor and talk to your team. Combine your quantitative KPI data with the qualitative insights from the people who experience these bottlenecks every single day.

For instance, your data might show a high MTTR for a particular machine. But a conversation with your maintenance crew could reveal the root cause: it’s an aging, complex piece of equipment that only one senior technician truly understands. When he’s on vacation or tied up elsewhere, minor issues snowball into major delays. Suddenly, you realize you have a knowledge-gap problem, not just a mechanical one.

Similarly, a low FPY on a new product line could be traced back to confusing assembly instructions. New hires might be struggling to interpret dense, 2D diagrams, leading to consistent errors that require costly rework.

This focus on using technology to solve real-world operational challenges is a growing trend. A recent Deloitte manufacturing outlook found that manufacturers now allocate around 30% of their operating budgets to technology, up from 23% the previous year. This spending is directly aimed at reducing waste and improving OEE and cycle times.

Creating Your Actionable Map

By blending hard data with on-the-ground feedback, you build a clear, actionable map of your biggest operational drags. This approach allows you to prioritize the problems that have the most significant impact on your bottom line.

This assessment is the bedrock for building a targeted business case for any new technology, including AR and VR. Instead of a vague desire for "improvement," you'll have a specific, quantifiable problem to solve. This makes it far easier to justify the investment and, more importantly, to measure its success down the line. If you’ve pinpointed machine downtime as a primary concern, you can start exploring powerful strategies like condition monitoring and predictive maintenance to get ahead of failures before they even happen.

Matching Immersive Tech to Real-World Challenges

Now your groundwork starts to pay off. You’ve pinpointed the biggest drags on your operation, and it's time to connect those specific problems to the right AR or VR tool.

This isn’t about chasing new technology for its own sake. It’s about being surgical—choosing a specific solution for a specific, measurable challenge on your factory floor. Let's walk through a few real-world scenarios where these tools make a difference and build a solid business case.

Tackling Equipment Downtime with AR Remote Assistance

Let's circle back to that classic bottleneck: equipment downtime, measured by Mean Time to Repair (MTTR). Imagine a complex CNC machine grinds to a halt. Your on-site technician is capable but inexperienced, and she can’t solve the problem. Meanwhile, your senior expert is across the country at another facility.

Traditionally, this meant losing money while waiting for the expert to travel, or attempting to solve a complex mechanical failure over a frustrating phone call. With AR, that entire dynamic changes.

Your on-site technician puts on a pair of AR smart glasses or uses a tablet. Instantly, she's sharing her point-of-view with the remote expert, who sees exactly what she sees from their own desktop. The expert can then overlay digital instructions, pull up schematics, or even circle a specific component right on her live feed.

The benefits here are immediate and measurable:

- Drastically lower MTTR: The expert guides the fix step-by-step, eliminating guesswork and getting the machine back online in a fraction of the time.

- Slashed travel costs: No more last-minute flights or associated expenses. You save thousands on travel while shrinking your carbon footprint.

- Real on-the-job upskilling: The junior technician isn't just following orders; she is learning directly from an expert, building valuable skills.

This is a knowledge transfer machine. You're digitizing your most valuable expertise and making it available on demand, anywhere you need it.

Getting People Proficient Faster with VR Training

Now, consider the challenge of getting new hires up to speed on a complex assembly line. This process directly impacts your First Pass Yield (FPY) and training budget. Traditional shadowing is slow, ties up your most experienced personnel, and can be risky when expensive machinery is involved.

This is a perfect use case for Virtual Reality.

VR training drops your new hires into a hyper-realistic, fully immersive simulation of the assembly line or a specific workstation. They can put on a headset and practice a complex task in a completely safe, zero-risk environment.

They can make mistakes, learn from them, and repeat the process until it's second nature—all without wasting raw materials or risking damage to real equipment. Studies show this kind of hands-on learning can boost retention rates by up to 75% over traditional methods. By the time they step onto the real factory floor, they’re not just trained; they are confident and competent.

Error-Proofing Your Quality and Design Work

Beyond maintenance and training, this technology is a game-changer for quality assurance and product development. Manual inspections are notoriously prone to human error and inconsistency, which means a higher defect rate.

Augmented Reality streamlines this process. An inspector using an AR device can overlay a digital twin or CAD model directly onto a physical part. The software can immediately flag any deviations, misaligned components, or tiny surface flaws the human eye might miss. It makes the entire workflow faster, more accurate, and easily repeatable.

The same principle applies to design and prototyping. Your engineering teams can be scattered across the globe but meet in a shared virtual space to walk around a full-scale 3D model of a new machine. They can simulate its operation and spot design flaws long before a single piece of metal is cut. This kind of collaborative VR shrinks development cycles and prevents expensive rework. You can see more real-world examples by exploring the many different augmented reality industrial applications being used today.

Adopting these kinds of smart factory approaches is a major global trend for improving productivity in manufacturing. The National Association of Manufacturers (NAM) has found that companies are increasingly using interconnected machines and real-time data to create factories that respond on their own to market shifts. It’s a move that boosts efficiency and cuts operational costs, with NAM’s own research showing smart factory solutions can increase productivity by 20-30%.

When you match the right immersive technology to your specific challenges, you stop experimenting and start creating targeted solutions that deliver real, measurable gains in efficiency, quality, and skill.

Kicking Off Your First AR or VR Pilot Program

Jumping straight into a full-scale, facility-wide rollout of immersive technology is a surefire way to fail. The smart way to improve productivity in manufacturing with AR or VR is to start small, prove the concept, and let the results build momentum. A focused pilot program is your most effective tool.

Think of it as a controlled experiment designed to generate undeniable data. You're not just testing new gadgets; you're building a rock-solid business case for a specific problem you've already pinpointed.

Define Your Target: Get Specific with Goals

The success of your pilot lives or dies by its objective. A vague goal like "improve efficiency" is useless because it cannot be measured. You need a goal that is specific, measurable, achievable, relevant, and time-bound (SMART).

Forget broad targets. Get granular with something like:

- "Reduce assembly errors on Line 3 by 15% within the first 60 days."

- "Drop the average Mean Time to Repair (MTTR) for our main stamping press by 25% this quarter."

- "Slash the onboarding time for new welding trainees by 40%."

These goals give you a clear finish line. Once the pilot is over, you can state exactly how successful it was, giving you the hard numbers needed to ask for a bigger investment. A great first step is exploring a structured virtual reality training program that can be built around these kinds of precise targets.

Pick the Right Problem and the Right People

Your first pilot should tackle a high-impact, low-risk problem. Look for a process that's a known bottleneck but won't bring your entire operation to a halt if there are unforeseen challenges. A complex assembly station that’s always behind schedule or a machine that needs frequent, tricky maintenance are perfect candidates.

Just as critical is the team you choose. Don't try to force this on skeptics. Instead, find a small crew of enthusiastic early adopters—the technicians and operators who are genuinely curious about new tools and motivated to find a better way. Their buy-in and feedback will be your most powerful internal marketing.

Choose champions, not conscripts. An engaged team that is excited to participate will actively look for ways to make the pilot successful and will provide the invaluable, honest feedback needed to refine your approach.

Choose the Right Tech and Track Everything

With a clear goal and an eager team, picking the hardware becomes much easier. The use case tells you what tool you need.

- Hands-on maintenance or assembly? AR smart glasses are your go-to. They keep the user's hands free while overlaying digital instructions right where they need them.

- Safe, immersive training? VR headsets are the obvious choice. They create a controlled world where trainees can practice complex or dangerous tasks with zero risk.

Once the pilot is running, your main job is data capture. Don't wait until the end—track your progress from day one. This means gathering both hard numbers and human feedback.

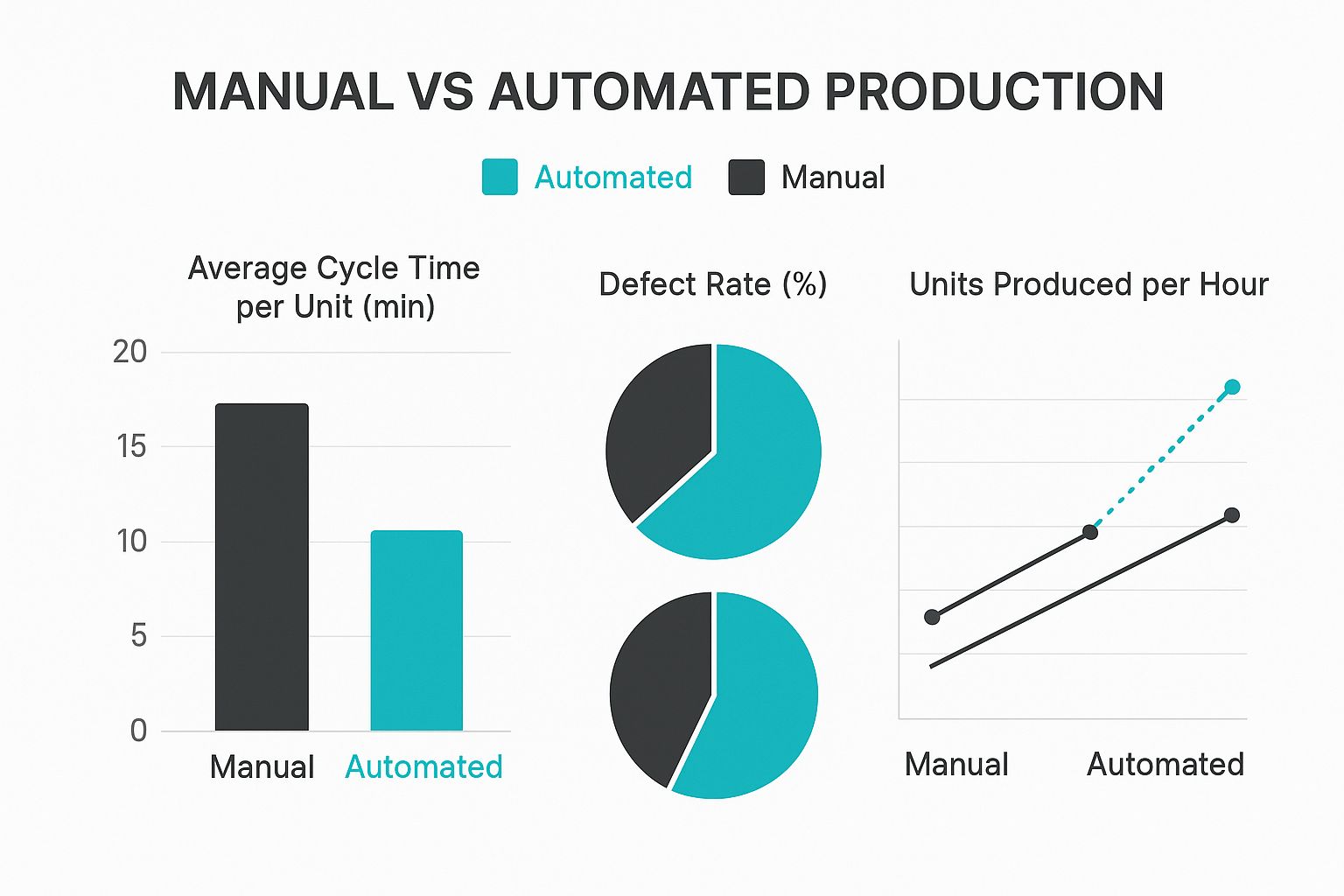

The image below gives a sense of the kind of performance shifts that good data can reveal when you're comparing different production methods.

This data shows a clear link between automation and improvements in cycle times, output, and defect rates—the very same kinds of gains you can expect to prove with a well-run AR/VR pilot.

To help you decide which path is right for your specific challenge, here’s a quick comparison of where each technology shines.

AR vs. VR Solutions for Manufacturing

| Use Case | Best Fit Technology (AR/VR) | Primary Benefit | Implementation Complexity |

|---|---|---|---|

| Complex Assembly Guidance | AR | Reduced errors, faster cycle times | Moderate |

| Remote Expert Assistance | AR | Lower MTTR, reduced travel costs | Low to Moderate |

| Safety & Compliance Training | VR | Improved knowledge retention, risk-free practice | Moderate |

| Equipment Operation Simulation | VR | Faster onboarding, reduced machine wear | Moderate to High |

| Quality Control Inspections | AR | Increased accuracy, better data capture | Moderate |

Both AR and VR offer powerful advantages, but matching the tech to the task is what separates a successful pilot from a frustrating one. This table should help point you in the right direction.

As you run the pilot, track everything related to your initial goal—cycle times, error rates, repair durations. But don't stop there. Talk to your team. Conduct quick interviews to get their take: Did the tool actually make their job easier? What was frustrating?

This mix of hard data and real user stories creates a narrative that's impossible to ignore. You can walk into a leadership meeting and say, "Our pilot cut errors by 18%, and the techs on the line told me it was the best job aid they've ever used." That's how you turn a small test into a full-scale transformation.

Scaling Your Solution for Long-Term ROI

A successful pilot is your launchpad, not the finish line. You’ve gathered compelling data and proved the concept on a small scale. Now comes the real challenge: turning that initial win into a sustainable, company-wide strategy that delivers real, long-term returns. This is how you genuinely improve productivity in manufacturing—by weaving immersive technology into the very fabric of your operations.

Scaling isn't just about ordering more headsets. It’s a strategic move that demands a solid framework for infrastructure, training, and, most importantly, financial justification. Making the leap from a single-use case to a full deployment is where a promising experiment becomes a lasting competitive advantage.

Building the Business Case with Pilot Data

Your pilot program was designed to generate proof, and now it's time to put that proof to work. The metrics you carefully tracked—things like reduced MTTR, lower error rates, or faster training times—are the foundation of your business case for a broader rollout.

When you present this to leadership, don't talk about tech specs. Talk about money. Frame your results in the language of business impact:

- "Our AR remote assistance pilot on Line 4 cut machine downtime by 22%. That translates to an estimated $150,000 in recovered production value this quarter alone."

- "Using VR to onboard new assembly techs, we got them up to speed 35% faster. That saved 80 hours of a senior supervisor's time that used to be spent on one-on-one shadowing."

Concrete data like this turns a funding request into a clear-cut investment opportunity with a payback period you can actually point to.

A well-documented pilot isn’t just about proving the technology works. It’s a strategic tool designed to secure the executive buy-in and resources needed for the next phase of implementation.

Creating a Phased Deployment Plan

Trying to launch a new technology across an entire facility—or multiple facilities—all at once is a recipe for chaos. A "big bang" rollout is almost guaranteed to fail. Instead, you need a phased deployment plan to minimize disruption and ensure a smooth transition. This lets you learn as you go, applying lessons from one stage to the next.

Your plan needs to methodically outline a few key things:

- Prioritization: Where will you get the biggest, fastest win? Start with the departments or production lines suffering from the most critical bottlenecks.

- Timeline: Get real about how long each phase will take. Factor in everything from hardware procurement and software setup to actually getting your people trained.

- Resource Allocation: Who owns what? Clearly define who's responsible for each piece of the rollout, from the IT folks handling the network to the on-the-floor champions leading the training.

A structured approach like this makes the whole process manageable and builds momentum with each successful phase you complete.

Addressing Infrastructure and IT Concerns Early

Scaling up immersive tech puts new demands on your IT infrastructure. You do not want to discover these roadblocks in the middle of a rollout. You need to get ahead of them.

Sit down with your IT department before you scale to assess and plan for:

- Network Bandwidth: High-quality AR and VR, especially anything involving video streaming for remote assistance, needs rock-solid Wi-Fi coverage across the shop floor.

- Data Security: How are you securing the sensitive operational data flowing through these devices? You need clear protocols for data management and storage that meet company and industry standards.

- Device Management: When you have a whole fleet of devices, you need a system. Think about how you’ll handle updates, user permissions, and even the physical logistics of storage and charging stations.

Tackling these technical requirements upfront ensures the technology remains a tool for productivity, not a source of frustration.

Driving Adoption with Comprehensive Training

Here’s a hard truth: the best technology in the world is useless if people won’t use it. Your training program is the single most important factor in driving user adoption. This has to go way beyond a simple "how-to" guide; it's about building confidence and showing people why this makes their job better.

A successful training blueprint always includes:

- Champion-Led Training: Find the enthusiastic early adopters from your pilot and turn them into peer trainers. A genuine endorsement from a coworker is far more powerful than any top-down mandate.

- Role-Specific Scenarios: Tailor the training to the job. A maintenance tech needs to learn a completely different set of skills than a quality inspector or a new machine operator.

- Ongoing Support: What happens after the training session ends? Create a clear channel for users to ask questions and get help. This could be a designated support person, a digital knowledge base, or regular check-in meetings.

Tracking Long-Term ROI and Continuous Improvement

As you scale, you have to be rigorous about measuring the impact. It's critical to know how to calculate ROI and make it a continuous process. Those metrics you tracked in the pilot? They should now become part of your standard operational reporting.

Constantly connect the use of AR and VR to sustained improvements in your core KPIs, whether that’s OEE, operational costs, or overall plant output.

This ongoing measurement doesn't just prove the long-term value of your investment; it also helps you spot new opportunities to apply the technology elsewhere. This data-driven approach ensures your immersive tech initiative doesn't just start strong—it becomes a central pillar of your continuous improvement culture.

Still Have Questions About Immersive Tech in Manufacturing?

Even with the best plan, diving into new technology always brings up some good questions. It's smart to have them. Tackling these concerns head-on is a huge part of making any new tech initiative stick.

Here are a few of the most common questions we hear from manufacturing leaders who are looking at AR and VR for their operations.

What’s the Biggest Hurdle with AR Implementation?

Surprisingly, it's rarely the technology itself. The real challenge is usually integrating the new AR tools with the systems you already have and, more importantly, getting your team to actually use them.

Knitting AR software into legacy platforms like your MES or ERP system takes some careful planning. You need to make sure data flows seamlessly between them. But the true make-or-break factor is workforce adoption. Your people need to feel comfortable and capable with new hardware like smart glasses.

A phased rollout works best. Start small, provide great training that shows exactly how the tech makes their jobs easier and safer, and pick an AR platform that’s intuitive from the get-go.

How Do You Actually Justify the ROI for a VR Training Program?

Figuring out the Return on Investment for VR training is more straightforward than you might think, as long as you track the right things. It’s all about comparing the new way against the old and putting real numbers on the improvements.

To build a rock-solid case, focus on a few key areas:

- Reduced Training Time and Costs: How many fewer hours does it take to get a new hire up to speed? Track the savings on instructor time and resources.

- Less Material Waste: When mistakes happen in a virtual world, it doesn't cost you a dime. Measure the drop in scrap materials and damaged equipment during the onboarding phase.

- Fewer On-the-Job Errors: Keep an eye on the number of safety incidents and production mistakes. Employees trained in VR tend to make fewer of both.

- Faster Time to Full Productivity: How quickly does a new employee hit their target output? When they get there faster, they start adding value to your bottom line sooner.

When you put hard numbers to these improvements, the financial return on that initial VR investment becomes incredibly clear.

Think of it this way: you’re shifting training costs from a recurring operational expense (think waste, rework, and supervisor time) to a one-time capital investment that pays dividends for years. That reframing makes the upfront cost much easier to justify.

Can a Smaller Manufacturer Really Afford This?

Yes, absolutely. This technology used to be the playground of massive corporations, but that’s changed. The cost of both AR and VR hardware has come way down. Even better, many of the most powerful software platforms are now offered on a subscription model (SaaS).

This means you don't need a massive capital outlay to get started. A small or medium-sized manufacturer can kick things off with a pilot program aimed squarely at its biggest bottleneck—maybe it’s one complex assembly station or a machine that’s always going down.

You can even start with AR on a simple tablet or smartphone to provide digital work instructions. The strategy is to start small, prove the value with clear wins, and then scale up once the productivity gains are undeniable.

How Do We Get Our Experienced Workforce to Adopt It?

Getting your veteran employees on board comes down to one thing: showing them what’s in it for them. This tech needs to be a tool that makes their jobs easier, safer, and less frustrating—not something that threatens to replace them.

Your most experienced people are your greatest asset, so bring them into the pilot program from day one. Their feedback is pure gold for getting it right, and their buy-in is contagious. When a respected senior tech starts raving about a new tool, everyone else pays attention.

Focus on simple, intuitive interfaces that don't require a computer science degree to operate. The "aha!" moment usually happens when a veteran worker uses an AR tool to diagnose a tough problem in 15 minutes instead of the 3 hours it used to take. Once they feel that firsthand, they often become the technology's biggest champions on the floor.

Ready to see how immersive AR and VR solutions can directly solve your biggest operational challenges? The experts at AIDAR Solutions tailor and integrate virtual training and remote service tools to meet your unique needs, delivering measurable productivity gains and rapid ROI.

Explore our solutions and start your transformation journey