Preventive vs Predictive Maintenance What to Choose

The preventive vs predictive maintenance debate boils down to one fundamental question: do you act based on a calendar or based on real-time data? To illustrate, preventive maintenance is changing your car's oil every 5,000 miles because the manufacturer recommends it. Predictive maintenance is changing it when a sensor indicates the oil's viscosity is actually starting to degrade.

The right choice isn't just about technology; it's a strategic decision that impacts operational efficiency, budget allocation, and asset longevity.

Choosing Your Ideal Maintenance Strategy

Selecting between preventive and predictive maintenance is a major decision that shapes your budgets, workflows, and tolerance for unplanned equipment failures. There is no single correct answer—the optimal approach depends on the specific assets in operation, the capital available for investment, and the business impact of unplanned downtime.

To make an informed choice, it is essential to understand the core principles of each strategy.

What Drives Each Approach

Preventive maintenance is the established, time-tested method. It is built on consistency, operating on a fixed schedule based on time or usage metrics. Inspections, parts replacements, and tune-ups are performed at regular intervals, which makes planning and budgeting highly straightforward.

Predictive maintenance, conversely, is a dynamic, condition-based strategy. It utilizes tools like IoT sensors to continuously monitor equipment health. This stream of data enables teams to intervene at the exact moment an asset requires attention, eliminating unnecessary work on perfectly healthy equipment.

The core difference is the trigger. Preventive is driven by a schedule. Predictive is driven by real-time data. One is about routine, while the other is about executing the right task at the precise moment it's needed.

This guide will provide a clear breakdown of the costs, benefits, and practical steps for implementing both. The goal is to provide the knowledge required to build a more efficient, lean maintenance program tailored to your operational needs. Understanding effective maintenance problem-solving is an excellent starting point for this journey.

Here is a quick side-by-side comparison to frame the key differences.

| Feature | Preventive Maintenance (Time-Based) | Predictive Maintenance (Condition-Based) |

|---|---|---|

| Trigger | Fixed schedule (e.g., every 3 months) | Real-time asset data and analytics |

| Cost Structure | Lower initial cost, higher long-term OPEX | Higher initial investment, lower long-term OPEX |

| Labor Use | Can lead to unnecessary, scheduled tasks | Highly efficient; work is only done when needed |

| Downtime | Planned and scheduled | Minimized, both planned and unplanned |

| Technology | Basic tools, CMMS for scheduling | IoT sensors, AI/ML, advanced analytics |

Understanding Preventive Maintenance Fundamentals

Let's begin with the classic approach: preventive maintenance. It is a straightforward, proactive strategy built on a simple principle: service equipment before it fails. This time-tested approach operates on a fixed schedule, meaning tasks like inspections, lubrication, and parts replacements occur at regular intervals, regardless of an asset’s current condition.

Consider the routine oil changes for a vehicle. You don't wait for the engine to fail; you perform the service every 5,000 miles to maintain smooth operation. The objective is to address potential problems before they can escalate into significant failures.

The Core Principle: Time-Based Actions

The entire philosophy hinges on the premise that failure probability can be reasonably estimated based on time or usage. A maintenance team might schedule a motor inspection every six months or replace a specific filter after every 1,000 hours of operation. This calendar-based system is simple to manage, especially with a basic Computerized Maintenance Management System (CMMS).

The advantage is predictability. You can plan downtime, order parts, and schedule technicians well in advance, which helps avoid the chaos associated with a sudden breakdown. However, this approach has weaknesses. Its main vulnerability is the risk of over-maintenance—expending time and resources on an asset that is not at risk of failure.

Servicing a perfectly healthy machine not only wastes resources but also introduces the risk of human error during the maintenance itself. Every time equipment is opened, there is a possibility of creating a new problem. Furthermore, the scheduled downtime may have been unnecessary, leading to lost production.

Despite the rise of more advanced alternatives, preventive maintenance remains the foundation for many operations. A 2017 study found that approximately 80% of maintenance personnel preferred it, which illustrates how deeply embedded this strategy is worldwide. You can find more insights on maintenance preferences from sources like LimbleCMMS.com.

Practical Applications and Ideal Scenarios

So, where does preventive maintenance excel? It is highly effective for less critical assets where the cost of an unexpected failure is relatively low. It is also a suitable fit for environments where installing sensors on every piece of equipment is not financially practical.

Practical use cases include:

- Routine HVAC Maintenance: Regularly cleaning coils and replacing filters in a commercial building's air conditioning system to maintain operational efficiency.

- Vehicle Fleet Management: Performing scheduled oil changes, tire rotations, and brake inspections on a fleet of delivery trucks based on mileage.

- Manufacturing Equipment: Lubricating conveyor belts and replacing worn components on an assembly line on a set weekly or monthly schedule.

The key trade-off with preventive maintenance is choosing predictable reliability over optimal efficiency. You might perform some unnecessary work, but you drastically reduce the odds of an unexpected catastrophic failure for assets that wear out in predictable ways.

Ultimately, this approach creates a solid foundation for reliability. While the discussion is often framed as preventive vs predictive maintenance, a well-executed preventive program is significantly better than purely reactive maintenance. It brings structure and control to asset management, forming the base upon which more sophisticated strategies can be built.

Exploring the Power of Predictive Maintenance

Predictive maintenance (PdM) represents a significant advancement from schedule-based servicing. It is centered on data-driven forecasting. This approach uses modern technology to continuously monitor the real-time health of equipment, transforming maintenance from a routine task into a precise, on-demand action. By analyzing asset performance data, you can intervene at the optimal moment—just before a failure occurs.

This strategy moves away from the calendar entirely. Instead of replacing a part every six months by default, PdM relies on Internet of Things (IoT) sensors to track metrics like vibration, temperature, and performance. This continuous data stream provides a live health report for every critical machine in your operation.

From Data Points to Actionable Insights

The true value is realized when sensor data is fed into artificial intelligence (AI) and machine learning (ML) algorithms. These systems are trained to identify subtle patterns and minute anomalies that are invisible to human observation—the early warnings that often precede a major failure.

Once the algorithm detects a deviation from normal operating conditions, it flags the asset for attention. This enables maintenance teams to intervene with surgical precision, resolving the specific issue before it can escalate into a costly, unplanned outage. The goal is simple: maximize asset uptime and utilize resources efficiently by performing maintenance only when it is genuinely required. You can take a closer look at the technology and strategies that power condition monitoring and predictive maintenance to understand its inner workings.

This shift from a fixed schedule to a condition-based trigger is the fundamental difference in the preventive vs. predictive maintenance debate. It is a move that prioritizes intelligence over routine.

The Financial and Operational Impact

The return on adopting a predictive model is significant and directly impacts the bottom line. Because work is performed only when required, PdM reduces unnecessary labor costs and eliminates the premature replacement of serviceable parts. This intelligent approach can cut overall maintenance costs by 10% to 40% while also extending the life of equipment. Trust in this data-driven method is growing rapidly; by 2018, adoption had already climbed to over 50% in some industrial sectors, up from 47% just one year earlier.

Predictive maintenance is the go-to strategy for high-value, critical assets where unexpected downtime can have catastrophic financial or safety consequences. It's about investing in intelligence to protect your most important operational components.

For advanced PdM, modern approaches often incorporate technologies like Building Information Modeling (BIM) to centralize and analyze asset data, leading to more accurate forecasts and proactive interventions.

The Role of AR and VR in Predictive Maintenance

Augmented and Virtual Reality (AR/VR) solutions are enhancing the effectiveness of predictive maintenance. When a predictive alert is generated, an on-site technician can use an AR headset to receive real-time guidance from a remote expert.

The remote expert sees exactly what the technician sees and can overlay digital instructions, diagrams, and data directly onto their view of the equipment. This capability significantly shortens resolution times and eliminates the need for expert travel. VR can be used to create immersive simulations for training technicians on complex failure scenarios flagged by the PdM system, preparing them for high-stakes repairs in a safe, controlled environment. These tools turn predictive insights into faster, more accurate results.

A Detailed Look at Two Maintenance Philosophies

Choosing between preventive and predictive maintenance requires a clear understanding of the trade-offs. While both strategies are designed to prevent failures, they achieve this goal through different means. These differences have a direct impact on your budget, your team's workload, and the overall reliability of your operation.

Let's move beyond basic definitions. This head-to-head comparison breaks down how each strategy performs against the criteria that matter most to your bottom line. A true preventive vs predictive maintenance analysis is not about declaring a single winner. It is about identifying which approach aligns with your specific assets and business objectives. One offers predictable scheduling and simplicity; the other provides surgical precision and long-term cost savings.

Cost and Return on Investment

Financial considerations are typically the starting point for this decision. Preventive maintenance is known for its lower upfront costs, primarily involving scheduling tools and labor rather than a large technology investment. However, its long-term operational expenses (OpEx) can increase over time due to scheduled parts replacements and labor hours that may not always be necessary.

Predictive maintenance reverses this model. It requires a significant capital investment (CapEx) in sensors, software, and data infrastructure. But this initial cost is designed to be offset by much lower long-term expenses. Maintenance occurs only when data indicates a developing problem, which eliminates substantial waste.

Multiple analyses show that a well-implemented predictive program can deliver savings of 8-12% over preventive methods, primarily by optimizing resource utilization and detecting problems earlier. For a deeper analysis of these figures, you can explore detailed maintenance statistics and trends.

Reliability and Asset Uptime

Both strategies are a significant improvement over a purely reactive, "fix it when it breaks" model, but they deliver reliability in different ways. Preventive maintenance reduces the likelihood of unexpected failures by adhering to a strict calendar. The limitation is that it cannot prevent failures that occur between scheduled checks. It also cannot prevent the small number of issues caused by the maintenance itself.

For your most critical assets, predictive maintenance provides a much higher degree of reliability. By continuously monitoring an asset's condition, it detects the earliest signs of a problem. This gives your team a longer lead time to plan and execute repairs, minimizing unplanned downtime and maintaining production continuity.

Predictive maintenance shifts the focus from avoiding probable failures to addressing actual, developing issues. This precision not only boosts uptime but also extends the operational life of the asset by avoiding premature component replacements.

Implementation Complexity and Data Needs

This is where the two paths diverge significantly. Implementing a preventive maintenance plan is relatively straightforward. It requires an asset inventory, manufacturer-recommended service intervals, and a system—often a CMMS—to track everything. The data requirements are minimal.

In contrast, deploying a predictive maintenance program is a more substantial project. It demands:

- Specialized Technology: IoT sensors, data acquisition systems, and powerful analytics platforms are essential.

- Data Expertise: You need staff skilled in data science or a strong partnership with a provider who can interpret the incoming information.

- System Integration: The predictive platform must integrate with existing work order systems to automatically generate alerts and initiate actions.

The foundation of predictive maintenance is a constant stream of high-quality data. Without accurate sensor readings and intelligent algorithms to interpret them, the entire strategy is ineffective.

Preventive vs Predictive Maintenance: A Feature Comparison

To clarify these differences, a side-by-side view is helpful. The table below breaks down how each strategy compares across the most important operational and financial criteria, offering a quick-glance guide to their core philosophies.

| Criterion | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Primary Trigger | Fixed Time or Usage Schedule | Real-Time Condition Data |

| Initial Cost | Low | High |

| Long-Term Cost | Higher (due to scheduled labor/parts) | Lower (optimized resource use) |

| Downtime Impact | Planned, but can be unnecessary | Minimized for both planned and unplanned events |

| Data Requirement | Low (schedules, checklists) | High (continuous sensor data, analytics) |

| Best For | Less critical, predictable assets | High-value, critical assets |

Ultimately, this comparison highlights that the "best" approach depends entirely on the asset in question. For a simple, non-critical conveyor belt, a scheduled check-up may be perfectly adequate. For a multi-million dollar piece of CNC machinery, real-time monitoring is the only way to ensure maximum uptime and longevity.

Practical Use Cases and Industry Applications

Let's transition from theory to practice. How do these maintenance strategies perform in real-world environments like the shop floor, the server room, or the field? The choice is not arbitrary—it is a calculated decision based on asset criticality, known failure patterns, and intervention costs.

Preventive maintenance is the reliable standard for equipment with predictable failure modes and manageable upkeep costs. It establishes a baseline of reliability for everyday, non-critical assets through rhythm and repetition.

Predictive maintenance is the specialized approach for high-stakes equipment. It is reserved for mission-critical machinery where an unexpected failure would be catastrophic, employing a precise, data-first methodology to protect your most valuable assets.

Preventive Maintenance in Action

The primary strength of preventive maintenance is its straightforward, predictable nature, making it ideal for managing large fleets of similar, less-critical assets without undue complexity.

Here are a few classic examples:

- Commercial HVAC Systems: A facility management team performs scheduled filter replacements and coil cleanings every quarter on all rooftop AC units. This simple routine prevents gradual efficiency degradation and addresses common wear-and-tear issues before they can cause a building-wide cooling failure.

- Manufacturing Assembly Lines: On a bottling line, technicians follow a weekly checklist to lubricate conveyor belts and a monthly schedule for replacing specific seals and gaskets. These components have a known lifespan, and replacing them on a schedule is far more cost-effective than an emergency production line shutdown.

- Fleet Vehicle Management: A logistics company services its delivery vans every 10,000 miles, including oil changes, tire rotations, and brake checks. This time-based system maintains the entire fleet's safety and availability, reducing breakdowns that disrupt delivery schedules.

High-Impact Predictive Maintenance Scenarios

Predictive maintenance demonstrates its value most clearly when applied to complex, high-value assets where a calendar cannot accurately predict failure. In these cases, monitoring real-time data provides a significant advantage, converting potential disasters into planned work orders.

Consider these powerful examples:

- Industrial Gearbox Monitoring: A factory uses acoustic sensors to detect subtle changes in the sound of a critical gearbox. An algorithm flags a high-frequency noise indicative of a microscopic gear tooth fracture, providing weeks of advance notice to schedule a replacement before a catastrophic failure halts production. To better understand these applications, see how top companies are using predictive maintenance in manufacturing.

- Electrical Infrastructure Safety: A data center utilizes thermal imaging cameras to continuously monitor its switchgear and transformers. The system automatically alerts staff when a connection's temperature rises just 5°C above normal—a clear indicator of a loose connection and a serious fire hazard, triggering an immediate inspection.

Enhancing Maintenance with AR and VR

Immersive technologies like Augmented Reality (AR) and Virtual Reality (VR) are adding a new dimension to both strategies, making technicians faster, safer, and more accurate.

AR and VR do not replace maintenance philosophies; they amplify them. They provide technicians with digital tools that enhance human capability, whether they are following a scheduled checklist or responding to a data-driven alert.

In a preventive maintenance scenario, a technician can wear an AR headset that overlays a digital checklist and step-by-step guides directly onto their view of the machine. This ensures every task is completed correctly and consistently.

For predictive maintenance, AR enables an on-site technician to receive live remote assistance from a senior expert. The expert can see what the technician sees and guide them through a complex repair flagged by the system. VR takes this a step further, allowing teams to practice responding to critical failure alerts in a safe, simulated environment, ensuring they are prepared for real-world events.

How to Implement the Right Maintenance Strategy

Deciding on the right maintenance strategy is not a simple choice between preventive vs predictive maintenance. The ultimate goal is to build a blended program that aligns with your operational realities—your budget, your team's skills, and, most importantly, the criticality of your assets. The most effective maintenance programs utilize both strategies where they deliver the most value.

This process begins with a thorough assessment of your own facility. A full-scale predictive maintenance deployment across every machine is rarely practical or cost-effective. A smarter approach is a hybrid model: use advanced predictive methods for your most critical assets and maintain reliable, cost-effective preventive schedules for everything else.

Conducting an Asset Criticality Assessment

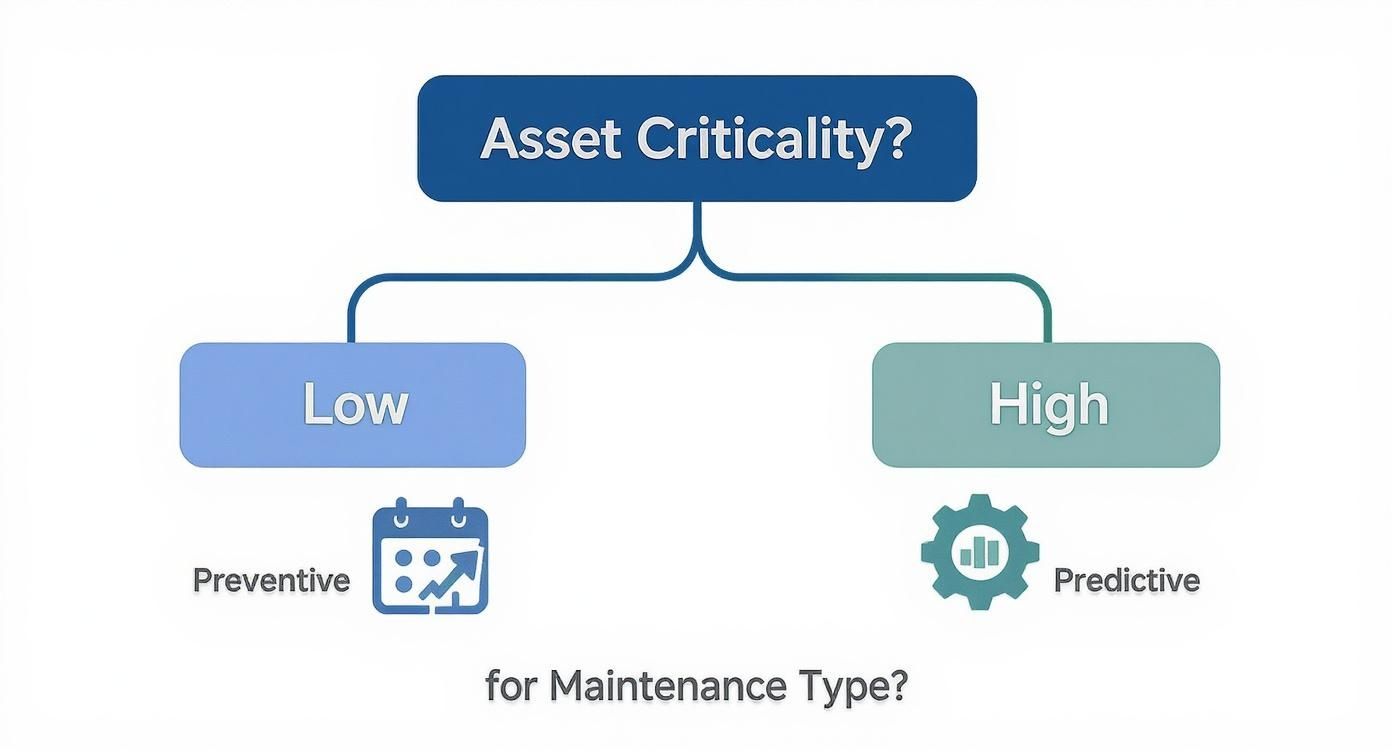

First, you must categorize your equipment. Not all assets are of equal importance, and your maintenance budget should reflect this. A straightforward way to start is by ranking them based on the operational impact of a potential failure.

- High-Criticality Assets: These are machines where unexpected downtime would cause major production losses, safety risks, or significant financial impact. Examples include a main power transformer or the central gearbox on a primary production line. These are ideal candidates for predictive maintenance.

- Medium-Criticality Assets: A failure here would be disruptive but not catastrophic. A secondary conveyor belt or a support pump might fall into this category. These assets are typically best served by a robust preventive maintenance plan.

- Low-Criticality Assets: This category includes redundant equipment or assets that are inexpensive and easy to replace, such as a small office HVAC unit. For these, a basic preventive schedule or even a run-to-failure approach is often sufficient.

This decision tree provides a visual for how asset criticality can guide your maintenance choices, pointing you toward preventive for less crucial items and predictive for your high-stakes equipment.

The key takeaway is that your strategy should be tailored asset by asset. You want to focus your resources where the risk is highest.

Rolling Out Your Strategy in Phases

Once your assets are mapped, a phased rollout is the recommended approach. It minimizes risk and helps build momentum. Instead of attempting a complete overhaul at once, start small to demonstrate value and secure buy-in from your team and leadership.

- Launch a Pilot Program: Select one or two high-criticality assets that have a history of issues. Implement a predictive maintenance solution exclusively for them to prove its ROI.

- Foster a Data-Centric Culture: The success of predictive maintenance depends on your team's trust in the data. Conduct targeted training to help technicians become comfortable with interpreting sensor readings and analytics alerts.

- Integrate Your Systems: A robust work order management system is essential for streamlining how tasks are assigned and tracked. This ensures that an alert from your predictive system automatically generates an actionable job for a technician.

- Scale with Confidence: Use the successes from your pilot program—such as documented cost savings from an averted breakdown—to build the business case for expanding the program to other critical assets.

The goal is not a rapid, facility-wide transformation. It is about building an intelligent, tiered maintenance program that evolves over time, asset by asset, proving its worth at every step.

This careful, deliberate approach allows you to build a maintenance program that genuinely enhances performance and delivers measurable business value. Modern tools can make this process even smoother. For example, you can learn more about how maintenance augmented reality solutions help guide technicians through both preventive and predictive tasks with greater accuracy and speed.

Frequently Asked Questions

When determining the optimal maintenance strategy, several practical questions about cost, complexity, and application frequently arise. Let's address some of the most common ones.

What Is the Main Difference Between Preventive and Predictive Maintenance?

The primary difference is the trigger for action. Preventive maintenance operates on a fixed schedule. Work is performed every six months or after 1,000 operating hours, regardless of the machine's actual condition.

Predictive maintenance, in contrast, is condition-based. It uses real-time sensor data to monitor what is happening inside a machine. Work is scheduled only when the data indicates that a failure is likely to occur. In short, action is based on evidence, not the calendar.

Can a Small Business Implement Predictive Maintenance?

Yes, but a strategic approach is necessary. Attempting to deploy predictive maintenance across an entire facility at once can be cost-prohibitive. The key is to start small.

Select one or two of your most critical assets—those where downtime would be most detrimental—and initiate a pilot project.

The accessibility of this technology has changed. More affordable IoT sensors and cloud-based analytics platforms have brought predictive maintenance within reach for smaller companies. It is now possible to demonstrate a clear ROI without a massive upfront investment.

Is It Better to Choose One Strategy Over the Other?

It is generally not advisable to choose one exclusively. The most successful organizations employ a hybrid model, leveraging the strengths of both approaches.

They apply data-intensive predictive maintenance to their high-value, mission-critical assets where an unexpected failure would be catastrophic. For all other less critical, more predictable equipment, they adhere to a simple, cost-effective preventive schedule. This balanced approach ensures that resources are allocated where they will have the greatest impact.

Ready to see how immersive tech can sharpen your maintenance operations? AIDAR Solutions builds AR and VR tools that help technicians get the job done faster and more accurately, whether they’re following a preventive checklist or responding to a predictive alert. Explore our solutions today.