Industrial Virtual Reality: Transforming Industry Operations

Industrial virtual reality represents a fundamental shift in how teams interact with complex machinery and workspaces.

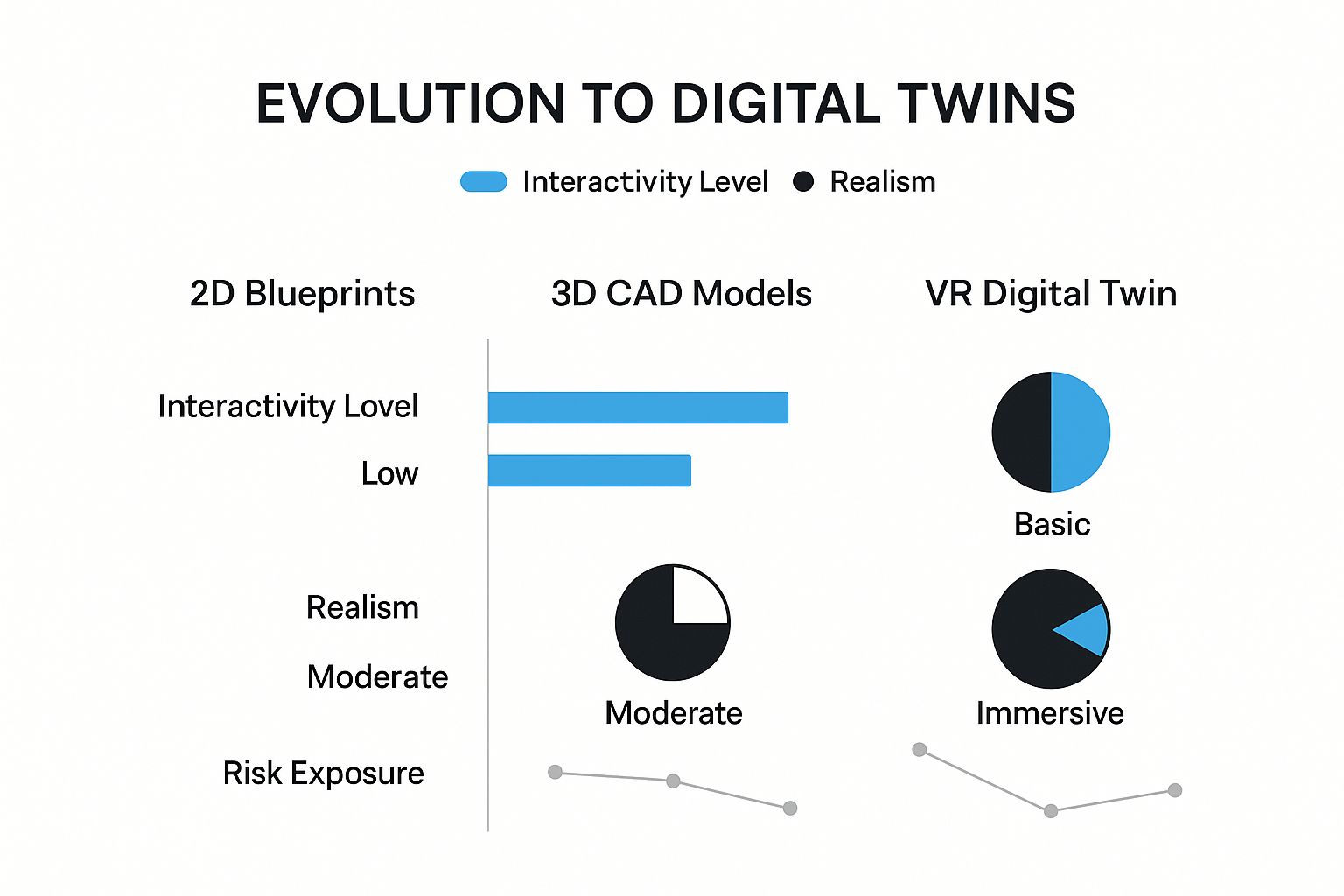

Moving from flat, 2D blueprints to interactive 3D CAD models was a significant leap forward. VR is the next evolution. It moves beyond the flat screen, immersing users into a fully interactive, true-to-scale digital world. This technology allows for the creation of precise digital twins of entire facilities, individual machines, and complex workflows.

What Is Industrial Virtual Reality

At its core, industrial virtual reality is a strategic tool that uses immersive, life-like simulations to solve real-world operational challenges. It creates a hyper-realistic, computer-generated replica of an industrial environment, giving teams a zero-risk space to train, plan, and troubleshoot.

Instead of merely observing a 3D model on a monitor, personnel can step directly inside it. They can walk around a machine, inspect it from every angle, and interact with it at a perfect 1:1 scale.

This hands-on approach is a significant departure from traditional methods. A standard operating procedure (SOP) manual or a training video is a passive experience. Industrial VR provides active practice that builds real muscle memory and sharpens critical thinking skills.

From Flat Blueprints to Immersive Worlds

The journey from paper schematics to immersive digital environments has been a game-changer for industrial operations. Each step has brought us closer to reality, offering more detail and interactivity that completely changes how projects get done.

- 2D Blueprints: These provided a basic, flat layout. They required significant mental effort to visualize in three dimensions and offered zero interaction.

- 3D CAD Models: By adding the Z-axis, CAD allowed engineers and designers to manipulate objects on a screen. This was a major improvement for visualization but remained a detached, third-person experience.

- VR Digital Twins: Users are no longer observers; they are fully present inside the digital model, interacting with it as if it were physically there. This first-person perspective is critical for truly understanding spatial relationships, ergonomics, and complex procedures.

This infographic illustrates the progression, showing how each leap in technology boosts realism while reducing real-world risk.

The move to a VR digital twin is about maximizing immersion and interactivity. The direct result is a significant reduction in risk exposure during critical training and planning stages.

The table below breaks down the practical advantages.

Industrial VR vs Traditional Methods

| Area of Operation | Traditional Method | Industrial VR Approach | Key Advantage |

|---|---|---|---|

| Technician Training | Classroom lectures, manuals, on-the-job shadowing. | Immersive, hands-on simulations of complex repair tasks. | Safe practice on rare or dangerous scenarios, building muscle memory without production downtime. |

| Facility Design | 2D blueprints, physical mock-ups, 3D screen-based walkthroughs. | Full-scale, interactive virtual walkthroughs of the proposed layout. | Identify ergonomic issues, safety hazards, and workflow bottlenecks before construction begins. |

| Complex Maintenance | Printed guides, phone support from an off-site expert. | Real-time, remote expert guidance overlaid directly onto the user's field of view. | Drastically reduced error rates, faster repairs, and minimized travel costs for experts. |

This isn't just an incremental improvement; it's a completely different way of operating that delivers measurable gains in safety, efficiency, and cost savings.

The Strategic Value of a Digital Twin

A digital twin is far more than a 3D model. It's a dynamic, virtual replica of a physical asset, process, or system. In an industrial context, this could be an entire factory floor, a single piece of complex machinery, or a specific assembly line.

By pairing these digital twins with virtual reality for industry, companies can unlock their true potential.

By creating a perfect digital copy of a real-world environment, organizations can test scenarios, train staff, and optimize processes without disrupting ongoing operations or endangering personnel. This capability is central to modern operational excellence.

For example, engineers can test a new production line layout by walking through the proposed setup in VR. They can spot potential bottlenecks, identify safety hazards, and check clearances before a single physical change is made. This foresight saves a tremendous amount of time and money, transforming facility planning from an exercise in guesswork into an act of precision.

Transforming Workforce Training with VR Simulations

One of the most impactful applications of industrial virtual reality is forging a workforce that's highly skilled, confident, and safe. Traditional training methods like dense manuals or classroom sessions are often insufficient for preparing personnel for the high-stakes reality of industrial environments. Immersive simulations transform training by placing trainees directly into realistic scenarios.

Consider a new technician learning a complex repair on a wind turbine. Instead of just reading about it, they can use a headset to run through the entire procedure in a perfect digital twin. They can practice handling tools, identifying components, and following the correct sequence until it becomes second nature.

This is not passive observation; it's about building genuine muscle memory and critical thinking. It provides a space where trainees can make mistakes, learn from them, and repeat the process without any real-world consequences—a capability unavailable when working with live, multi-million-dollar equipment.

Building Expertise in a Zero-Risk Environment

The core benefit of VR training is the creation of a safe space to fail. In industries where one wrong move can lead to catastrophic equipment damage or serious injury, this is a fundamental shift in the approach to training.

With VR, companies can simulate hazardous procedures or emergency protocols that are impossible to replicate safely in real life. A factory crew can run through a full emergency shutdown, or a chemical plant operator can tackle a simulated system failure, all without disrupting operations or putting anyone in harm's way.

This zero-risk training model does more than just teach—it builds confidence. When an employee has already performed a challenging task multiple times in a simulation, their first time on the real equipment feels familiar, not intimidating. They are more precise and far less apprehensive.

This approach covers everything from routine jobs to rare but critical "what-if" scenarios, ensuring teams are prepared for any situation.

Key Advantages of VR-Based Learning

Switching to immersive training delivers concrete, measurable results. It moves away from a passive, one-size-fits-all model and into an active, personalized experience that directly boosts on-the-job performance.

Here are some of the primary benefits:

- Accelerated Onboarding: New hires get hands-on experience with machinery from day one, reducing the time it takes for them to become productive.

- Reduced On-the-Job Errors: Because VR builds deep procedural knowledge, personnel make fewer mistakes. Studies indicate immersive learning can lead to a 75% higher retention rate compared to traditional lectures.

- Enhanced Safety Culture: When teams regularly practice responding to emergencies and handling hazardous materials in VR, safety becomes an instinct, not just a checklist.

By focusing on these practical outcomes, companies can build a stronger, more capable workforce. To go even deeper, you can explore the primary benefits of virtual reality training and see how it’s reshaping employee development.

Practical Applications Across Industries

The flexibility of industrial VR makes it a valuable tool for any organization dealing with complex machinery or high-consequence work.

A car manufacturer rolling out a new robotic assembly line can train staff in a virtual replica without shutting down production. When the real line goes live, the team is already up to speed, minimizing downtime and costly integration errors.

An aerospace company can train technicians on intricate engine assembly. VR lets them visualize and interact with components at a 1:1 scale, understanding how every part fits together long before they touch a single physical piece. It’s not just about improving skill; it’s about protecting priceless components during the learning curve. These examples show VR is not just another training tool—it's a strategic asset for operational continuity.

Accelerating Product Design and Prototyping

Beyond training, industrial virtual reality is fundamentally changing how products are designed, refined, and brought to market. The traditional path from concept to physical prototype has been slow and expensive, often hindered by multiple rounds of costly physical mockups. VR helps dismantle that bottleneck.

Imagine an engineering team designing a new piece of heavy machinery. Instead of gathering around a monitor to view a CAD model, they can use headsets to step inside their creation. They can walk around it at a true 1:1 scale, check clearances with absolute precision, and see exactly how every component fits together—long before any physical material is used.

This immersive process allows teams to identify design flaws that are nearly invisible on a flat screen. An inaccessible maintenance panel or a component that clashes with another during assembly becomes immediately obvious when you can virtually reach out and interact with it.

From Digital Blueprints to Interactive Prototypes

This shift from passively viewing a design to actively interacting with it is where VR prototyping delivers immense value. It gives designers and engineers the opportunity to experience their products from the end-user's perspective, which consistently leads to more intuitive and ergonomic designs.

The business impact is significant. The industrial virtual reality market in manufacturing is projected to grow from $924.7 million in 2018 to an expected $14.8 billion by 2026. This growth is driven by VR's proven ability to sharpen product design and make production workflows more efficient. You can discover more insights about this trend and how companies are reducing costs with virtual reality.

This is not just about saving money on materials; it's about compressing the entire development cycle.

Validating Ergonomics and Assembly Before Production

One of the most powerful uses of industrial VR is in human-centric design. By simulating how a person will interact with a product, teams can validate ergonomics and safety at the beginning of the process.

- Ergonomic Assessments: Is a control panel on a new dashboard easy to reach? Can a technician access a key part for maintenance? VR provides instant, intuitive answers, preventing expensive redesigns.

- Assembly Process Simulation: Teams can run through the entire assembly sequence in a virtual space. This helps them identify bottlenecks, optimize the order of operations, and create clear instructions for the factory floor.

- Maintenance Procedure Validation: Before a product ships, maintenance crews can use VR to walk through complex repair jobs. This ensures serviceability is integrated into the design, not addressed as an afterthought.

By testing human factors in a virtual space, companies can eliminate the guesswork from design. This leads to products that are not only functional but also safer and more efficient for the end-user to operate and maintain.

For example, an auto manufacturer can place a virtual human in the driver's seat of a new car design to instantly check sightlines, gauge the reach to the console, and ensure adequate headroom—all without creating a physical mockup. This reduces design time and results in a better, more user-friendly vehicle.

This ability to iterate on designs almost instantly fuels real innovation. When the cost and time of creating physical prototypes are virtually eliminated, engineers are free to experiment with bolder ideas. It creates a powerful cycle where new concepts can be tested, refined, and validated in a fraction of the time, giving companies a significant competitive advantage.

Improving Maintenance and Remote Assistance

Beyond the design studio and training room, industrial VR and augmented reality (AR) are proving their value in maintaining operational uptime. When critical machinery goes down, every second of downtime impacts revenue. The traditional method of flying in a senior expert is slow, expensive, and often impractical.

Immersive technology changes this dynamic. It closes the distance between seasoned engineers and technicians on the ground, creating a direct link that empowers local teams to solve complex problems faster and more accurately.

Consider a field technician on a remote offshore platform facing a critical equipment failure. Instead of waiting days for an expert, they can use AR smart glasses to share their exact point-of-view with a senior engineer located thousands of miles away. This "see-what-I-see" capability is the foundation of modern remote assistance.

Real-Time Guidance from Anywhere

The technology goes beyond sharing a video feed. The remote expert can guide the on-site technician by overlaying digital information directly onto their real-world view.

This is a form of digital telepresence. The expert can draw on the technician's screen, highlight specific components, and push step-by-step instructions that appear anchored to the physical machine. A complex repair transforms into a clear, guided process.

The benefits are immediate:

- Drastically Reduced Downtime: Problems that previously took days to resolve while waiting for an expert can now be fixed in hours.

- Elimination of Travel Costs: The significant expenses of flights, hotels, and logistics associated with deploying specialists are eliminated.

- Empowered Local Teams: On-site technicians learn by doing, solving complex problems with expert oversight. This builds their confidence and skills, creating a more capable workforce.

With this technology, companies can make their best expertise available on-demand, anywhere in the world, without the delays and costs of physical travel.

A Practical Scenario: Offshore Repair

Let's return to the technician on the offshore platform. A critical pump has failed, and the local crew lacks the specialized knowledge for this particular repair.

Using AR glasses, the technician initiates a call. The remote expert sees the pump exactly as if they were there. They immediately identify the faulty component and overlay a digital arrow pointing to it. "Start by loosening these four bolts," the expert says, digitally circling them on the technician's screen.

As the technician works, the expert pulls up a 3D schematic of the pump and places it in their peripheral view for reference. Every step is guided with visual cues and verbal confirmation, leaving no room for error. In just two hours, the pump is repaired and back online—a fix that would have previously taken up to three days and cost tens of thousands in travel and lost production.

This real-time collaboration bridges the skills gap instantly. It ensures that even the most complex or infrequent maintenance tasks are performed correctly the first time, every time, by the personnel already on site.

The applications for this are massive and growing every day, providing a clear competitive advantage in operational efficiency.

The Impact on Operational Efficiency

The value of remote assistance extends beyond a single emergency repair. Integrating this capability into daily operations builds a more resilient and efficient maintenance workflow. It helps standardize procedures across all sites and ensures best practices are followed consistently.

Furthermore, every remote assistance call becomes a powerful training opportunity. The on-site technician learns directly from an expert, gaining hands-on experience that sharpens their skills for the future. This continuous upskilling strengthens the entire organization by reducing reliance on a few key experts. The end result is a maintenance operation that is faster, safer, and more cost-effective.

How to Measure the ROI of Industrial VR

While the technological benefits are clear, stakeholders require a quantifiable return on investment. The value of VR translates directly into financial and operational gains that can be tracked. Calculating the ROI for industrial VR involves looking beyond the initial cost of hardware and software to the cost reductions and efficiency boosts across the entire operation.

Identifying Tangible Cost Reductions

The most direct way to measure ROI is through direct cost savings. These are expenses that can be significantly reduced or eliminated by replacing traditional methods with a VR-based approach. This data is compelling for leadership as it represents clear financial impact.

Three areas typically deliver immediate savings:

- Reduced Travel Expenses: Flying an expert to a remote facility for a single repair is costly. With VR-powered remote assistance, that expert can guide a local technician in real-time. This can cut travel costs by 75% or more and restore operations much faster.

- Fewer Physical Prototypes: Building physical mockups for product design consumes time, money, and materials. VR allows engineers to create, test, and refine full-scale digital prototypes, identifying design flaws early without physical production.

- Lower Traditional Training Costs: Conventional training often requires shutting down a production line, hiring instructors, and using raw materials. VR simulations eliminate these needs. Trainees get risk-free, repeatable practice without disrupting the factory floor.

Quantifying Crucial Efficiency Gains

Beyond direct savings, industrial VR is a major driver of operational efficiency. While these metrics may seem less direct, their financial impact is often greater than upfront cost reductions. These gains in productivity, quality, and speed create a positive ripple effect across the business.

The true value of industrial VR emerges when you measure its impact on how work gets done. Faster onboarding, fewer errors, and reduced downtime are not just operational goals—they are powerful financial levers.

When building a business case, focus on these key performance indicators (KPIs):

- Faster Employee Onboarding: VR training can help new hires become fully productive up to 75% faster. This means less time shadowing and more time contributing.

- Decreased Machine Downtime: When an expert can guide a fix remotely in hours instead of days, the savings from avoided production losses can be substantial.

- Fewer Production Errors: Immersive training builds muscle memory and procedural accuracy, leading to a measurable decrease in on-the-job mistakes, which translates to less scrap, rework, and wasted materials.

To accurately measure this, it is important to establish a baseline before implementing the technology. Our guide explains how to measure training effectiveness with clear, actionable steps.

A Simple ROI Calculation Example

Let's illustrate with an example. A manufacturing company invests $100,000 in a VR training and remote assistance platform for its maintenance crew.

Here is a potential breakdown of annual returns:

| Metric | Traditional Annual Cost | Cost with Industrial VR | Annual Savings |

|---|---|---|---|

| Expert Travel | $80,000 | $20,000 | $60,000 |

| Downtime Losses | $150,000 | $75,000 | $75,000 |

| Training Material/Waste | $25,000 | $5,000 | $20,000 |

| Total Annual Savings | $155,000 |

In this scenario, the $155,000 in annual savings delivers a full ROI on the initial $100,000 investment in less than eight months. Presenting this type of clear financial breakdown shifts the conversation from technology to a strategic business decision.

The Future of Immersive Industrial Technology

Industrial VR is a dynamic platform that continues to evolve. The next wave of innovation involves blending VR with other advanced technologies to create even more powerful and intuitive tools that will continue to drive efficiency and redefine industrial operations.

One of the most exciting frontiers is the integration of artificial intelligence (AI) with VR training. Imagine simulations that are not fixed scenarios but adaptive learning environments. An AI-powered system could monitor an employee's performance in real-time, identify weaknesses, and dynamically adjust the simulation's difficulty to reinforce specific skills.

This allows for the creation of a personalized training path for every user. If a technician struggles with a particular step, the AI could introduce new challenges or offer targeted feedback until mastery is achieved. This moves away from a one-size-fits-all model toward a highly efficient, individualized coaching experience.

From Sight to Touch with Advanced Haptics

The next level of immersion will come through the sense of touch. Integrating industrial VR with advanced haptics—technology that simulates touch through forces, vibrations, or movements—will be a game-changer. Haptic gloves and full-body suits will allow users to "feel" the virtual tools and parts they are working with.

This will add a significant layer of realism and, more importantly, build genuine muscle memory. A trainee won’t just see themselves tightening a bolt; they’ll feel the resistance of the virtual wrench. This tactile feedback is crucial for mastering jobs that require a delicate touch or precise force, making simulations more effective.

The ability to feel digital objects as if they were real bridges the final gap between simulation and reality. This advancement will significantly deepen learning retention and skill transfer from the virtual world to the physical one.

The Rise of the Industrial Metaverse

Looking further ahead, the concept of the industrial metaverse is emerging. This involves creating persistent, shared virtual workspaces where global teams can collaborate as if they were in the same room. Engineers from different continents could meet inside a factory's digital twin to walk around virtual machinery together and conduct a design review.

This growth is supported by significant market expansion. The global virtual reality market is expected to reach $382.87 billion by 2033, a substantial increase from $43.58 billion in 2024. This expansion is fueled by technological upgrades like motion tracking and haptic feedback that make these industrial applications increasingly viable. You can explore the full virtual reality market growth trends to see how this is impacting different sectors.

Ultimately, industrial VR is evolving into a deeply interconnected platform. By integrating AI, haptics, and shared virtual spaces, it will continue to break down geographic barriers, enhance human capabilities, and unlock new levels of operational excellence across every industry.

Your Questions Answered

When considering bringing industrial VR into your operations, practical questions about cost, hardware, and return on investment are common. Let's address them.

What’s the Real Cost and What Hardware Do I Need?

The investment for an industrial virtual reality program varies. A focused pilot program for a single task may start in the tens of thousands of dollars, while a full-scale, enterprise-wide rollout represents a larger investment. The final cost depends on the complexity of your simulations and whether you use a ready-made platform or develop a custom solution.

On the hardware side, you will need VR-ready PCs with powerful GPUs and a set of enterprise-grade headsets for high-resolution visuals. Depending on the application, you might also add peripherals like haptic gloves to simulate touch or advanced tracking systems for a fully immersive environment.

How Quickly Will We See a Return on Investment?

The timeframe for seeing a return depends on the application, but it can be surprisingly fast.

In safety training, the ROI can be almost immediate by preventing a single serious incident. For maintenance and remote support, most companies start seeing returns within 6-12 months from reduced travel costs and decreased equipment downtime.

In product design, the ROI comes from shorter development cycles and reduced use of physical materials for prototypes. Financial benefits often accumulate within the first year. Each application has a clear path to measurable gains.

Ready to accelerate your team's learning and cut operational costs with immersive tech? See how AIDAR Solutions can build a VR or AR solution for your specific industrial needs and deliver a fast, tangible return on your investment. Find out more at https://aidarsolutions.com.