A Guide to Augmented Reality Safety in the Workplace

Augmented Reality (AR) has moved beyond consumer applications to become a critical safety tool in the industrial world. AR safety involves overlaying digital information—such as warnings, step-by-step instructions, or live equipment data—directly onto a worker's view of the real world.

The primary objective is to proactively prevent accidents. AR is a powerful way to boost situational awareness, especially in high-risk environments like a factory floor or a construction site. By delivering the right information at the exact moment it is needed, complex jobs become guided, nearly error-proof procedures.

Beyond Gaming: How AR Redefines Workplace Safety

Imagine a technician wearing smart glasses on a bustling factory floor. As they look around, potential hazards—like a hot surface or a high-voltage area—are instantly highlighted in their vision. This is the new reality of industrial safety.

This is a critical professional tool designed to prevent injuries. However, a delicate balance must be struck. The real challenge is using AR to enhance a worker’s awareness without becoming a dangerous distraction. Implemented correctly, AR is a life-saving asset. Done poorly, it can increase cognitive load when a worker needs to be most focused.

The Proven Impact of Immersive Safety

The results speak for themselves. Implementing AR in industrial training and daily operations delivers real, measurable improvements.

The mining industry, for example, saw a 43% drop in lost time due to injuries after rolling out VR and AR safety training. In the medical field, surgeons who trained with AR-assisted simulations made 40% fewer mistakes during procedures compared to those using traditional methods. You can dive deeper into how different sectors are using this technology in our guide on augmented reality for businesses.

These numbers demonstrate that AR creates realistic, risk-free training environments where people can build the muscle memory and confidence they need to stay safe on the job. For more data-backed results, you can read the full research on VR and AR training statistics.

Augmented reality transforms safety from a reactive checklist into a proactive, intuitive system. By embedding critical information directly into a worker's line of sight, it reduces guesswork and human error where it matters most.

In the sections that follow, we'll provide a clear roadmap for maximizing the benefits of AR safety while managing the risks, creating a workplace that’s not just more efficient, but safer for everyone.

Managing the Risks of AR Distraction

Integrating augmented reality into the workplace introduces a critical challenge: cognitive overload. An AR display can be compared to a car's dashboard. A well-designed one provides just the vital information, cleanly, helping you focus on the road.

A cluttered, messy one does the exact opposite—it becomes a dangerous distraction. Human attention is a limited resource, and a poorly designed AR interface can quickly deplete it.

When that happens, it can lead to inattentional blindness. This is when a worker becomes so focused on the digital information in front of them that they completely miss real, physical hazards in their path.

The Psychology of Digital Distraction

The issue is rooted in how our brains process information. When an AR interface presents a constant stream of data, non-essential notifications, or confusing visuals, it forces the brain into overdrive just to filter out the noise. This mental fatigue is what compromises situational awareness.

Distraction is one of the biggest safety hurdles for AR, as it can pull a user’s attention away from their surroundings and increase the risk of accidents. For example, some studies have shown an increase in incidents related to AR-assisted navigation tools due to user distraction. The key to mitigating this is thoughtful, purpose-built interface design.

The goal of an AR safety interface isn't to show everything possible. It's to show only what's necessary, at the exact moment it's needed. Less is almost always more.

Ultimately, the line between a helpful tool and a genuine liability is drawn by its design. The amount of information shown, the placement of overlays, and the user's interaction methods all determine if AR sharpens focus or splits it dangerously.

Designing for Focus and Safety

To prevent cognitive overload, the user experience (UX) and user interface (UI) must be built from the ground up with a "safety-first" mentality. This requires a deep understanding of human-computer interaction, especially in loud, busy industrial settings.

A few key design principles are non-negotiable:

- Context is King: The system should only show information that’s relevant to the task at hand. A technician fixing a pump doesn’t need to see inventory levels for the entire warehouse popping up in their view.

- Keep it Simple: Use clean, universally understood icons and short, clear text. Avoid flashy animations or complicated graphics that steal focus from the real world.

- Put the User in Control: Let people easily turn information on and off. They need to be in charge of their digital view, able to clear away distractions with a simple voice command or gesture.

Getting the user interface right is a specialized skill. It’s worth learning from the leading augmented reality UI design agencies that specialize in this field. By making a clean, intuitive, and context-aware interface a top priority, companies can ensure their AR tools are true safety assets, not digital hazards.

Putting AR Safety to Work in High-Risk Industries

The practical value of AR safety is realized when it is in the hands of workers on the ground. In high-risk fields, AR isn’t a futuristic concept; it's a practical tool that's already preventing accidents by delivering the right information at the right time.

Consider a utility crew preparing for an excavation. Before a single shovel breaks ground, a worker can use an AR headset to see a full map of buried gas lines, water mains, and electrical cables layered directly over the physical worksite. This transforms a high-stakes task into a precise, safe operation.

This is the core value of AR in any industry where a mistake can have serious consequences. It gives workers the power to see the unseen and tackle complex jobs with greater confidence.

Real-Time Guidance for Complex Jobs

One of the most immediate benefits of AR safety is providing step-by-step digital instructions right in a worker's line of sight. Imagine a technician performing a complicated lockout-tagout procedure for the first time.

Instead of consulting a physical manual, they see digital arrows and notes projected directly onto the equipment, guiding them through each step. The system can even confirm that each action is completed in the correct sequence, making it nearly impossible to miss a critical safety check. This in-the-moment guidance is a game-changer, especially for newer employees or during non-routine tasks.

Guided workflows like these are already making an impact across many sectors. For a closer look at how this technology is being rolled out, check out our guide to augmented reality industrial applications.

Seeing the Whole Picture

On a busy construction site or a loud factory floor, maintaining situational awareness is a full-time job. AR helps cut through the noise by feeding workers a heads-up display of crucial data.

For instance, a site manager could glance at a steel frame and see real-time structural load data, or an electrician could see live voltage readings on a control panel without ever opening it. The ability to access this kind of information without looking away from the task at hand is a fundamental leap forward for safety.

By layering digital intelligence onto the physical world, AR gives frontline workers a kind of "x-ray vision," allowing them to spot and handle hazards that would otherwise be completely hidden.

How Different Industries Are Using AR

AR safety is not a one-size-fits-all solution; its applications are shaped by the unique risks of each industry. Whether it’s getting assistance from a remote expert or identifying a hazard before it becomes a problem, the technology provides a vital layer of operational awareness.

- Energy and Utilities: A field technician can connect with a senior engineer who sees exactly what they see. That expert can then draw instructions directly into the technician's view, guiding a complex repair on high-voltage equipment from a safe distance.

- Manufacturing: On an assembly line, AR can highlight pinch points, moving parts, or hot surfaces on machinery in real-time, acting as a constant, dynamic safety reminder for operators.

- Aerospace: Maintenance crews use AR to overlay complex wiring diagrams directly onto a plane's fuselage, ensuring 100% accuracy and compliance with incredibly strict safety protocols.

These are field-tested solutions proving that AR has become an essential part of the modern industrial safety toolkit. It removes guesswork from dangerous jobs, reinforces correct procedures, and ultimately builds a safer workplace for everyone.

Enhancing Safety Training with Immersive AR

Traditional safety training often involves reviewing slide decks or reading dense manuals. While the information is present, these passive methods often fail to prepare teams for the split-second decisions required during an actual incident.

This is where augmented reality safety training changes the entire approach by shifting learning from passive to active.

AR bridges the critical gap between theoretical knowledge and practical application. It allows teams to walk through hands-on training scenarios in a completely controlled, zero-risk environment. Instead of just reading about a chemical spill protocol, they can physically walk through the entire containment procedure with digital guides overlaid on their view, steering them every step of the way.

This type of immersive experience is excellent for building procedural muscle memory. When employees can physically practice responding to a hazard, the correct actions become second nature, which makes all the difference under pressure.

From Basic Operations to Crisis Simulation

One of the greatest advantages of AR training is its flexibility. A full curriculum can be developed that scales with a team's skill level, creating a learning path that is both manageable and effective. This allows an employee to progress from foundational tasks to complex emergency drills.

A well-designed AR program can cover a wide range of scenarios, each tailored to specific job roles and their unique risks. A new hire might start with a simple module on operating a piece of machinery, with AR highlighting key controls and safety features. A seasoned technician, on the other hand, could be placed in a complex simulation of a full-blown equipment failure.

The key benefit is the ability to practice high-stakes situations without any of the actual risk. This hands-on experience is crucial for building both competence and confidence. You can explore a variety of these applications in our detailed guide on augmented reality for training.

With AR, mistakes become invaluable learning opportunities, not costly accidents. Trainees can fail, reset the simulation, and try again until the correct procedure is mastered, all without endangering themselves, their colleagues, or company assets.

Achieving Measurable Safety Outcomes

The impact of AR-based safety training is not theoretical; it delivers real, measurable results that make the workplace safer. By moving beyond simple memorization, this approach ensures a deeper understanding and dramatically boosts information retention.

To see just how different the two approaches are, let's compare them side-by-side.

AR Safety Training vs Traditional Methods

| Metric | Traditional Training (e.g., Manuals, Classroom) | AR-Enhanced Training |

|---|---|---|

| Knowledge Retention | Low to moderate; often requires frequent refreshers. | Significantly higher due to active, hands-on learning. |

| Time to Competency | Slower; requires bridging the gap from theory to practice. | Up to 4x faster as skills are built in a practical context. |

| Engagement | Passive; can lead to disinterest and "check-the-box" mentality. | Highly engaging and interactive, promoting active participation. |

| Error Reduction | Limited; errors can only be discussed, not practiced. | Up to 90% reduction in on-the-job errors after training. |

| Safety | Requires on-the-job training, which carries inherent risks. | 100% safe environment for practicing high-risk scenarios. |

The data shows that organizations that embrace immersive training see clear improvements across key safety and performance metrics.

- Faster Competency: Employees get up to speed on new procedures much more quickly because they're learning in a realistic context from day one.

- Improved Performance Under Pressure: After rehearsing emergency scenarios, workers are far less likely to panic and more likely to follow the correct protocols when it counts.

- Fewer On-the-Job Incidents: This is the most important outcome—a real, measurable drop in workplace accidents and safety violations. Better training leads directly to safer behaviors.

Ultimately, AR elevates safety training from a simple compliance checkbox to a powerful tool for operational excellence. It gives the workforce the practical skills and confidence needed to handle any situation, creating a more resilient and secure environment for everyone.

A Framework for Implementing AR Safety Programs

Successfully rolling out an augmented reality safety program requires more than just purchasing new equipment. It takes a deliberate, structured approach that begins with understanding specific risks and ends with empowering the workforce. A thoughtful framework ensures the technology effectively makes your team safer and more efficient.

The entire process should be built on solid risk analysis. An effective AR safety program is grounded in comprehensive operational risk management, which focuses on identifying and neutralizing potential hazards before they cause problems. This first step is critical for pinpointing the exact operational areas where AR can make the biggest safety impact.

Starting with a Thorough Risk Assessment

Before any software is installed, a detailed assessment of the work environment is necessary. This is not just another safety audit; it's an opportunity analysis. Walk the factory floor, talk to frontline workers, and identify tasks that are complex, carry high-consequence risks, or frequently lead to errors.

Look for areas where information gaps are causing safety incidents. Are technicians struggling with unfamiliar machinery? Do assembly line workers need better situational awareness? Answering these questions helps define the problems AR is intended to solve, ensuring your investment addresses genuine needs.

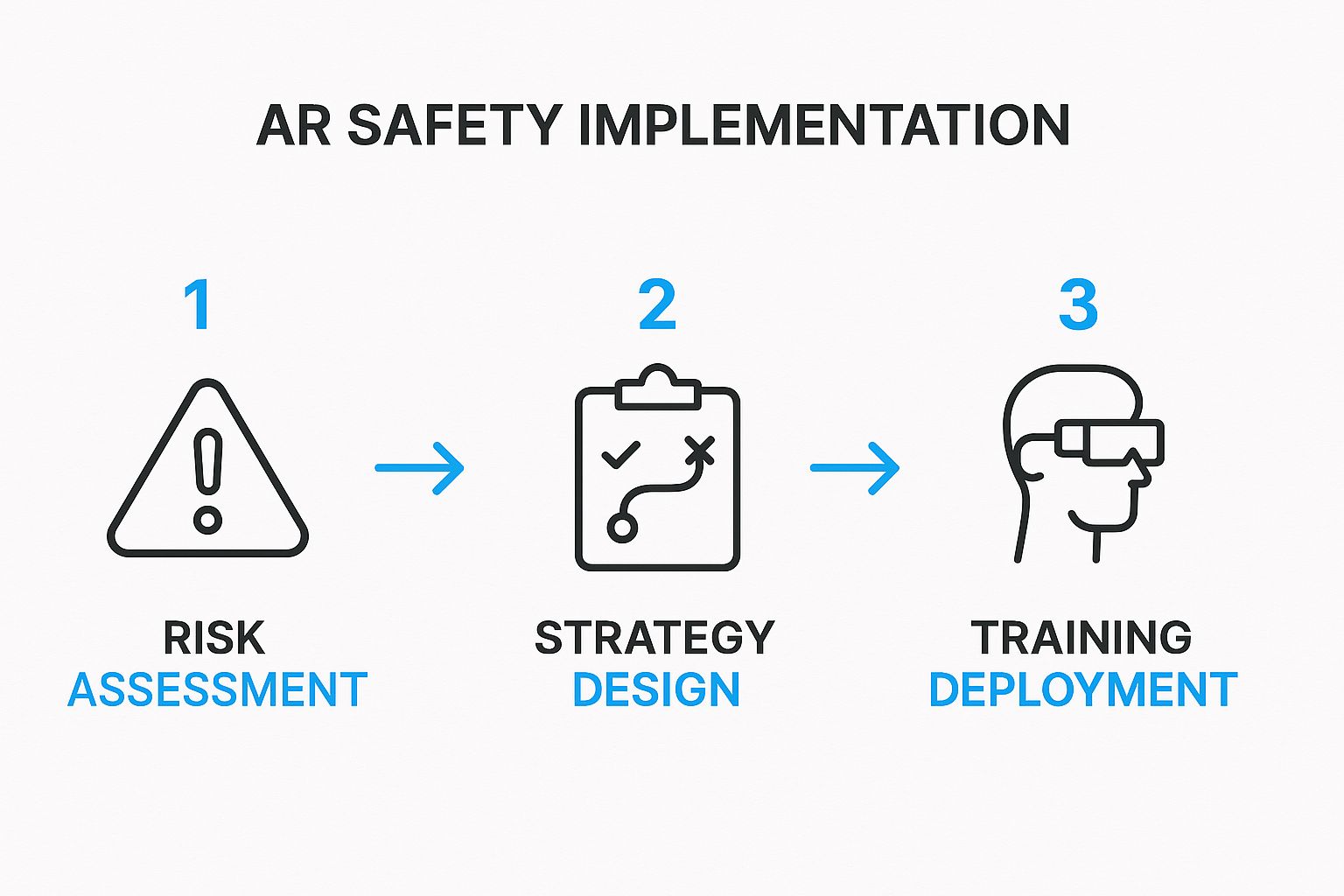

The infographic below breaks down the core stages of a successful AR safety implementation, from initial analysis to final deployment.

As you can see, a successful program flows logically from understanding risks to designing a targeted strategy and, finally, to effective training. Each step builds on the last, creating a solid foundation for your team to embrace the new tools.

Designing and Piloting the Solution

Once high-risk areas have been identified, it's time to design the AR solution itself. This involves selecting the right hardware—whether rugged smart glasses or tablets—and pairing it with software that delivers crucial safety information without causing cognitive overload. User-centric design is non-negotiable here.

The interface must be intuitive, showing only what is necessary for the task at hand. Before a full-scale deployment, launch a pilot program with a small, dedicated group of end-users.

A pilot program is your most valuable source of feedback. It allows you to identify and fix usability issues, hardware limitations, and workflow conflicts in a controlled setting before they impact your entire operation.

Getting direct input from the people who will actually use this technology every day is the key to long-term success. Their insights will help fine-tune the solution, ensuring it is a practical tool, not a frustrating gimmick. Our experts can provide more details on using augmented reality for industry to tackle specific operational challenges.

Establishing Clear Protocols for Deployment

The final stage is the full rollout, which must be guided by clear and comprehensive usage protocols. This framework should cover every aspect of the program's daily management and long-term health.

Your deployment plan must address several key areas:

- Standard Operating Procedures (SOPs): Document clear guidelines for how and when AR devices should be used for specific tasks. This eliminates guesswork and ensures safety protocols are applied consistently.

- Training and Onboarding: Develop a training module that not only teaches employees how to use the hardware but also explains the why behind the new procedures. This helps secure buy-in and encourages proper use.

- Device Management and Maintenance: Establish a system for charging, storing, updating, and servicing the AR devices. A well-maintained fleet of hardware is essential for reliability and building user trust.

- Data Security and Privacy: Define strict protocols for handling the data collected by AR devices. It is essential to ensure that both corporate information and employee privacy are protected at all times.

By following a structured framework—from assessment to deployment—you can integrate AR into your operations safely and effectively. This creates a more resilient safety culture built on better information and empowered workers.

Still Have Questions About AR Safety?

You're not alone. Even with a solid plan, adopting augmented reality for safety brings up specific, practical questions. Let's tackle some of the most common ones we hear from organizations making this move.

The goal here is to clear up any lingering doubts and provide the confidence needed to make the right decisions for your team.

What Are the Biggest Hardware Hurdles for AR Safety Right Now?

AR hardware has advanced significantly, but a few realities still need to be managed when selecting a device. Battery life is a major consideration. If teams work long shifts or in remote locations without easy access to charging, a device that fails mid-shift is not a viable solution.

Another key factor is the field of view (FOV). Some headsets have a narrow display, which can limit a worker's peripheral vision and reduce their awareness of their surroundings.

Finally, ergonomics are critical. A headset that is too heavy, bulky, or uncomfortable will cause fatigue and distraction, defeating the purpose of using technology to improve safety.

The most effective way to address these hurdles is to test the hardware in your actual work environment. Pilot programs and trials are the only way to confirm if a device can handle the physical demands and shift lengths your team faces every day.

How Do You Actually Measure the ROI of an AR Safety Program?

Measuring the return on an augmented reality safety program involves a combination of hard data and softer, but equally important, operational gains.

The direct, quantifiable metrics are typically used to justify the budget. These are factors with a clear dollar value:

- A reduction in workplace incidents and injuries.

- Lower insurance premiums resulting from an improved safety record.

- Reduced costs from accidents, such as damaged equipment or lost production time.

However, the indirect benefits are where AR demonstrates its long-term value. Consider improved training retention, faster task completion for complex jobs, and reduced cognitive strain on workers, which naturally leads to fewer errors. A comprehensive ROI calculation considers both the direct safety savings and the significant efficiency gains to show the full picture.

Can AR Replace All Existing Safety Training?

No, it is more effective to think of AR as a powerful tool to enhance your existing safety training, not replace it entirely. AR is brilliant for creating immersive, hands-on simulations and providing workers with real-time guidance on the job.

However, the human element cannot be replaced. Foundational knowledge, building a strong safety culture, and the mentorship provided by an experienced trainer are still absolutely critical. AR cannot replicate a nuanced conversation or the cultural buy-in that comes from great team leadership.

The best approach is a blended learning model. Use traditional methods to build a solid foundation of safety knowledge. Then, introduce AR to allow employees to practice high-risk tasks in a completely safe virtual space, reinforcing everything they’ve learned. This combination creates a truly effective and lasting safety mindset.

Ready to build a safer, more efficient workforce with immersive technology? AIDAR Solutions specializes in creating AR and VR applications that deliver measurable results. From virtual training that accelerates learning to remote support that empowers your frontline teams, we build solutions that fit your unique operational needs. Discover how we can help you implement a successful AR safety program.