Augmented Reality Industrial Applications Uncovered

Augmented reality is fundamentally changing how industrial businesses operate. By layering digital information directly onto the physical world, AR provides frontline workers with critical data and guidance exactly when they need it. This technology offers a direct solution to major challenges like operational inefficiencies, the widening skills gap, and the constant pressure to improve workplace safety.

Why Industrial Operations Are Embracing AR

Imagine a factory floor where a new technician sees complex assembly steps projected directly over the machine they are building, guiding them with precision. Or picture a field service professional arriving on-site, looking at a piece of equipment, and instantly seeing its entire repair history and live diagnostic data through their smart glasses. This is the new reality being built with industrial AR.

At its core, AR works by projecting digital content—schematics, step-by-step instructions, or live data feeds—onto a user's view of their actual surroundings. This seamless blend of digital and physical reduces the cognitive load on workers, allowing them to perform their tasks faster, more accurately, and with fewer mistakes.

Overcoming Modern Industrial Hurdles

Today's industrial sector is facing significant pressure. Seasoned experts are retiring, leaving a substantial skills gap that is difficult to fill. Simultaneously, global competition demands increased speed and efficiency. AR steps into this gap as a practical, powerful solution.

By providing on-demand visual guidance, AR essentially places an expert over the shoulder of every employee. It closes the experience gap by making institutional knowledge available to anyone, anywhere, at any time.

This instant access to information empowers workers to solve problems independently, which is critical for maintaining operational uptime and production flow. It is also transforming how companies train and support their teams.

A Rapidly Growing Market

The move toward augmented reality in industrial applications is a major market shift backed by significant investment. The technology is proving its value, and capital is flowing in accordingly.

By 2025, the AR industry is poised to reshape the industrial landscape. Projections show the AR market is expected to exceed $50 billion and continue climbing toward $88.4 billion by 2026. This explosive growth is driven by a compound annual growth rate of 31.5% between 2023 and 2026, signaling a massive vote of confidence from businesses worldwide. You can explore 2025 AR market trends on resources.imagine.io. This momentum is why forward-thinking companies are moving quickly to integrate AR into their core operations to maintain a competitive edge.

Transforming Manufacturing and Assembly with AR

On the factory floor, precision and speed are paramount. Even a minor mistake during a complex assembly can lead to costly rework, wasted materials, or a faulty product. This is where augmented reality becomes a practical, value-driving tool. AR overlays a digital layer of guidance onto the real world, helping workers perform tasks correctly the first time.

Consider a technician building a complex gearbox. Instead of frequently looking away from their work to consult a paper manual or a laptop, they wear smart glasses. These glasses project 3D instructions onto the physical gearbox, indicating which screw to tighten next, displaying the exact torque value, and confirming the correct orientation for each part. This technology is a game-changer for focus and accuracy.

This approach nearly eliminates "context switching"—the disruptive back-and-forth between a task and its instructions, which is a significant source of human error. By keeping the worker's eyes and attention on the task at hand, augmented reality for manufacturing makes the entire process more intuitive and efficient.

Boosting Assembly Accuracy and Speed

One of the most immediate benefits of AR in manufacturing is on complex assembly lines. When dealing with products that have hundreds or thousands of parts, the potential for error is massive. AR acts as an intelligent, interactive guide that moves at the worker's pace.

The economic impact is significant. Augmented reality is already making its mark, with projections showing it could add a $360 billion boost to the global GDP by 2030. Companies like Airbus utilize AR headsets to provide workers with visual, step-by-step guidance for assembling aircraft interiors, resulting in clear gains in efficiency, accuracy, and safety.

This digital guidance provides several key benefits:

- Error Reduction: By visually confirming each step, AR can reduce assembly errors by over 90%, particularly for new or less experienced team members.

- Increased Throughput: With instructions appearing exactly where needed, workers spend less time deciphering manuals and more time performing the work, resulting in faster production cycles.

- Standardization: AR ensures every worker follows the exact same procedure every time, creating consistent product quality across all shifts and facilities.

Reinventing Quality Control and Assurance

Beyond assembly, AR is also transforming quality control (QC) processes. Traditional methods often rely on manual inspections, which can be slow and inconsistent, especially when identifying minor defects or subtle deviations.

AR-powered quality checks work by overlaying a perfect 3D digital model of a part directly onto its real-world counterpart. Through an AR device’s camera, any misalignment, missing component, or structural flaw is instantly highlighted.

This digital overlay acts like a high-precision stencil, making even the smallest imperfections stand out immediately. It turns a subjective visual check into an objective, data-driven verification process, catching flaws that the human eye might otherwise miss.

This is invaluable in industries with tight tolerances, such as aerospace, automotive, and medical device manufacturing. On a broader scale, initiatives like Canada’s Critical Battery Materials Initiative demonstrate how deeply advanced technology is reshaping industrial processes.

Accelerating Workforce Training and Upskilling

Finally, AR offers a powerful solution to the industrial skills gap. Training new hires on complex machinery has traditionally been a slow, resource-intensive process, often requiring valuable equipment to be taken offline or tying up a senior mentor for weeks.

With AR, new employees can learn directly on the job in a safe, guided environment. An AR application can walk them through machine operations, routine maintenance, or tool changeovers with interactive, on-screen prompts. This hands-on, in-context learning is far more effective than traditional methods.

It dramatically shortens the learning curve, helping new workers become productive and confident in a fraction of the time. This not only reduces training costs but also minimizes the risk of beginner mistakes on the live production line, protecting both the employee and the equipment.

Empowering Field Service with Remote Expertise

The impact of augmented reality extends beyond the factory. It is fundamentally reshaping how businesses support their products and customers in the field, transforming complex logistical challenges into streamlined processes. This is where the true power of augmented reality industrial applications becomes evident—connecting teams and solving problems faster than ever.

At the heart of this shift is the "see-what-I-see" capability. A technician, potentially hundreds of miles from headquarters, can share their real-time point of view with a senior expert back at the office. This live feed, streamed through smart glasses or a mobile device, gives the expert a firsthand look at the problem as if they were physically present.

This immediate visual connection completely changes the troubleshooting process. The expert sees the exact situation, hears the machine’s performance, and can guide the on-site technician with precision. This eliminates the frustrating and error-prone back-and-forth communication over the phone, where critical details can be lost in translation.

Real-Time Guidance and Digital Annotation

Seeing the problem is one part of the solution; interacting with it is another. The real value emerges when the expert can digitally engage with the technician’s environment. Using AR, they can place digital notes, diagrams, and instructions directly into the technician's field of view.

Imagine an expert circling the exact valve that needs replacing, drawing an arrow to the correct diagnostic port, or displaying step-by-step instructions that appear to float in mid-air next to the component. It is more than a video call; it is a shared, interactive workspace.

This approach delivers significant benefits for field operations:

- Reduced Equipment Downtime: Problems are diagnosed and fixed in a fraction of the time, getting critical machinery back online quickly.

- Significant Travel Savings: Senior experts no longer need to travel for every complex issue, saving on flights, hotels, and related expenses.

- Higher First-Time Fix Rates: With expert guidance, technicians are far more likely to resolve the issue on the first visit, eliminating costly repeat trips.

By bringing the expert to the problem virtually, companies can dramatically reduce the time a machine is out of service. A repair that might have taken days while waiting for an expert to arrive can now be completed in a matter of hours.

This is not just about fixing things faster; it also serves as a powerful on-the-job training tool. Less experienced technicians learn directly from senior staff, building their skills and confidence with every guided repair.

Instant Access to Critical Information

In addition to remote assistance, AR gives technicians instant, hands-free access to a wealth of information. A technician can simply look at a machine’s serial number or QR code, and an AR application can instantly retrieve its entire history.

This on-demand data means no more searching through binders or using a laptop. Everything they need is right in front of their eyes. For companies looking to optimize their support operations, understanding the full scope of augmented reality for maintenance is the first step toward building a more responsive and effective team.

This instant data can include:

- Service History: A complete log of every past repair, maintenance check, and part replacement.

- Operational Data: Live sensor readings, performance statistics, and active error codes.

- Technical Manuals: Interactive 3D models and schematics overlaid directly onto the equipment.

By equipping field technicians with these tools, businesses can turn every service call into a faster, smarter, and more successful resolution. It elevates the technician from an instruction-follower to a highly capable problem-solver with all the necessary information in their line of sight.

The Measurable ROI of Industrial AR

Investing in any new technology must be justified by business value, and augmented reality is no different. While the immersive visuals are impressive, the real conversation begins when AR is connected to tangible, data-backed results.

This is where the discussion shifts from technology for its own sake to a strategic investment in bottom-line growth. It is about building a solid case for ROI by examining the key performance indicators (KPIs) that matter to industrial leaders.

The impact is evident in four critical areas: operational efficiency, error reduction, worker safety, and training effectiveness. These are measurable improvements that directly affect profitability and competitive advantage.

The market's explosive growth supports this. Valued at USD 3.48 billion in 2017, the global AR market grew to USD 5.91 billion by 2018. It is now projected to reach nearly USD 198.17 billion by 2025. This level of growth indicates that the technology is delivering real, concrete value. You can find more details on this trend from scoop.market.us.

Driving Operational Efficiency

One of the first areas to see a financial return is in pure efficiency. In manufacturing and field service, time is money. Any slowdown—whether it’s a technician searching for a manual or a machine sitting idle while waiting for an expert—directly impacts margins.

AR addresses this by delivering the right information at the right time, right where it’s needed.

AR remote assistance is a prime example. Instead of flying a senior expert to a site, which can take days, a local technician can connect with them instantly. The expert sees what the technician sees, guiding them through diagnosis and repair in real time. As a result, critical machinery is back online in hours, not days, saving significantly on production losses.

The financial impact is clear:

- Reduced Travel Costs: Companies report cutting expert travel budgets by over 75%, eliminating millions in transportation and accommodation costs.

- Improved First-Time Fix Rates: With expert guidance, technicians resolve issues correctly on the first visit, avoiding expensive repeat trips.

- Faster Task Completion: Hands-free access to schematics and step-by-step instructions helps workers complete complex tasks 30-50% faster.

Slashing Error Rates and Rework Costs

Mistakes in manufacturing or field service are incredibly expensive. They lead to wasted materials, hours of rework, and the risk of product recalls that can damage a brand's reputation.

AR-guided instructions act as a powerful safeguard against human error.

By overlaying digital guides directly onto a physical component, it becomes much more difficult to miss a step or use the wrong part. In complex assembly, companies have seen error rates drop by over 90% within the first week of implementation.

Think of AR as an interactive quality control system integrated directly into the workflow. It validates each step as it happens, catching potential issues before they become costly problems.

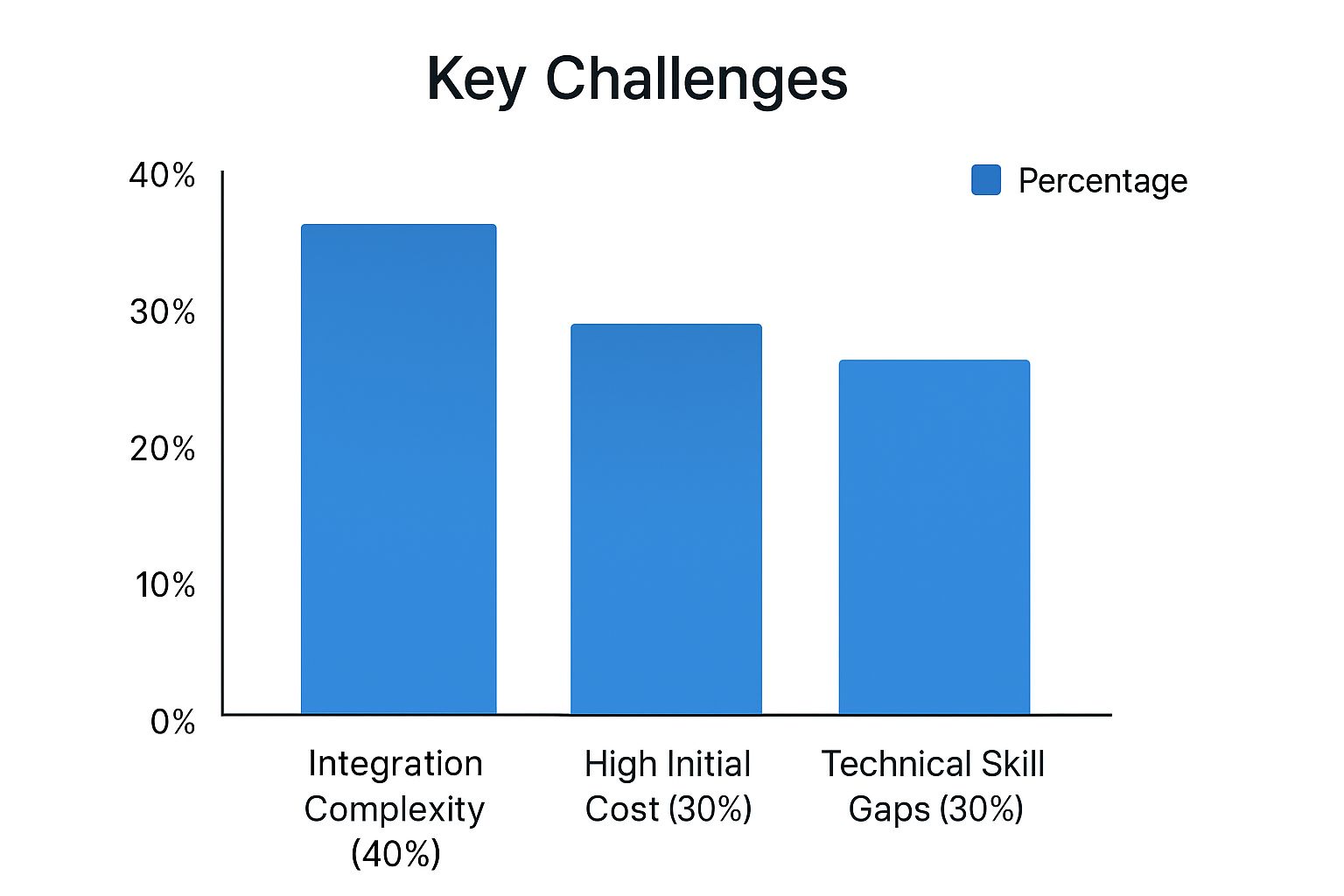

Of course, implementation has its challenges. Planning for these hurdles is key. This chart outlines the most common roadblocks businesses encounter when adopting AR.

As the data shows, the complexity of integrating AR with existing systems is the biggest barrier, which highlights the need for a well-planned, phased rollout strategy.

Accelerating Training and Improving Safety

The costs of training a new employee are substantial, including the instructor’s time, wasted materials, and potential production slowdowns. AR offers a faster, safer, and more effective way to bring new staff up to speed.

New hires can learn complex jobs in a guided, interactive environment, practicing on real equipment without the risk of making costly mistakes.

This approach not only reduces training time—by up to 75% in some cases—but also dramatically improves information retention. Furthermore, by providing clear visual warnings for safety procedures and highlighting potential hazards in real time, AR helps create a safer workplace, reducing accidents and their associated costs.

To maximize the benefits of these programs, it’s crucial to know how to measure training effectiveness with the right data.

Impact of AR on Key Industrial Metrics

To summarize, here is how AR directly impacts the metrics that matter most in an industrial setting.

| Operational Area | Challenge Without AR | Improvement with AR | Key Metric Impacted |

|---|---|---|---|

| Field Service | High travel costs, low first-time fix rates, long equipment downtime. | Instant remote expert assistance, guided digital work instructions. | Mean Time to Repair (MTTR), First-Time Fix Rate, Travel Costs. |

| Manufacturing Assembly | High error rates, costly rework, long assembly cycle times. | Step-by-step visual overlays, real-time quality validation. | Error Rate, Rework Percentage, Assembly Time. |

| Employee Training | Long ramp-up times, high material waste, safety risks. | "Learn-by-doing" simulations, on-demand procedural guidance. | Time to Competency, Training Costs, Incident Rate. |

| Maintenance | Inefficient procedures, reliance on paper manuals, machine downtime. | Hands-free access to schematics, IoT data visualization on equipment. | Overall Equipment Effectiveness (OEE), Maintenance Costs. |

Ultimately, the data shows that augmented reality is not a futuristic expense but a practical investment that delivers measurable returns by making operations smarter, faster, and safer.

Your Roadmap for a Successful AR Rollout

Embarking on an augmented reality initiative may seem like a massive undertaking, but with a strategic, phased approach, it is both manageable and highly effective. A well-planned rollout distinguishes a technology project from a genuine operational upgrade. This guide provides a practical roadmap for getting started with industrial AR applications.

The key is to start small and demonstrate value quickly. A large, company-wide deployment can lead to complexity, confusion, and resistance. Instead, begin with a targeted pilot program that solves one specific, high-impact problem.

Find a High-Impact Use Case

First, pinpoint a single, measurable problem that AR is well-suited to solve. Analyze your operations and ask: where are errors most frequent? What is causing the longest delays or driving up training costs? A complex assembly process that consistently requires rework is a classic—and highly effective—starting point.

Here are a few ideas for a first project:

- A single, complex assembly process: Select one station where mistakes are common and trigger expensive rework.

- A specific maintenance procedure: Focus on a piece of equipment that demands specialized knowledge and frequently causes downtime.

- A quality control checkpoint: Identify an inspection step that is slow, subjective, or prone to human error.

By narrowing your focus, you create a controlled environment to test the technology, gather hard data, and show a clear return on investment. This initial win builds the momentum needed for a broader rollout.

Pick the Right Hardware and Software

With a use case identified, it is time to choose your tools. Not all AR hardware is the same; the best choice depends entirely on the job and the environment. For an employee at a stationary assembly bench, a mounted tablet might be a perfect, cost-effective solution. For a technician on the move who needs their hands free, smart glasses are the more appropriate choice.

The software is just as critical. Your AR platform must integrate with your existing systems, whether an Enterprise Resource Planning (ERP) or a Manufacturing Execution System (MES). This integration is non-negotiable. It allows the AR application to pull live work orders, schematics, and operational data, making the information truly useful in the moment.

The goal is to make the technology fit the workflow, not the other way around. The right hardware and integrated software should feel like a natural extension of a worker's skills, making their job easier, not more complicated.

Prioritize Data Security and Integration

Introducing any new connected technology into an industrial setting requires a focus on data security. Your AR solution will handle sensitive information, from proprietary product designs to performance metrics. It is vital to partner with a provider who has robust security protocols.

Ensure all data transmission is encrypted and that the platform meets your industry's specific data privacy standards. A thorough security review before deployment will prevent major issues later and protect your intellectual property.

Win Over Your People for Enthusiastic Adoption

This may be the most important step. Technology is only as effective as the people willing to use it. Rolling out AR is as much about change management as it is about the technology itself. Start by clearly communicating the "why" behind the new tools.

Frame the technology as a way to empower your team—to make their jobs safer, less frustrating, and more efficient. It is a tool, not a replacement. Involve frontline workers in the pilot program from the beginning. Their feedback is invaluable for refining the process and helps build a sense of ownership. A well-designed onboarding program is essential, and you can learn more about how augmented reality for training can accelerate this process and build employee confidence. When you turn your team into champions for the technology, you help ensure its long-term success.

What's Next for the AR-Powered Workforce?

Looking ahead, augmented reality is set to become even more deeply integrated into the industrial fabric, often in conjunction with other powerful technologies. The future is not just about overlaying information; it is about creating intelligent, predictive systems that identify problems before they occur.

This is where AR’s full potential comes to light. Imagine an AR system that not only guides a technician through a repair but, powered by artificial intelligence, also predicts an imminent equipment failure. It alerts the technician, visually highlights the component at risk, and provides the exact proactive maintenance steps needed to prevent downtime.

A More Connected and Responsive Future

The rollout of 5G networking will accelerate this evolution. With ultra-fast, low-latency connectivity, complex and data-heavy remote collaborations will occur without lag. An expert could manipulate a high-fidelity 3D model in real-time for a technician thousands of miles away, making the experience feel as if they were in the same room.

This convergence of technologies creates a new reality on the factory floor:

- AR + IoT: A technician looks at a machine and sees live sensor data from the Internet of Things (IoT) overlaid directly on the equipment. They can visualize temperature, pressure, and vibration in real-time, getting an instant health check.

- AR + Digital Twins: A worker interacts with a digital twin—a perfect virtual replica of a physical asset. They can safely test new procedures or troubleshoot issues in the virtual world before interacting with the actual, high-value equipment.

This shift creates the 'connected worker'—an employee equipped with a constant stream of real-time data, predictive insights, and instant expert guidance. They are no longer just reacting to problems; they are becoming proactive problem-solvers.

To successfully integrate AR and prepare your team for this shift, it is crucial to explore effective workforce planning methods. This forward-looking vision makes it clear: businesses that want to build the competitive, resilient industrial operations of tomorrow need to begin their AR journey today.

Let’s Talk About Industrial AR: Your Questions Answered

Adopting any new technology raises questions. When it comes to industrial AR, leaders want to know about costs, compatibility with current systems, and how to measure return on investment. Let's address these key points.

What's the Real Cost of Getting Started?

The cost of AR implementation can be managed effectively. While a full-scale deployment is a significant investment, a pilot project can be surprisingly affordable.

The cost depends on three main factors: the hardware (ranging from tablets to high-end smart glasses), software licensing, and the integration services required to connect the solution to your existing systems. The most practical approach is to start small. Select a single, high-impact problem, prove AR’s value, and then scale up once a clear ROI is established.

Will AR Play Nicely with Our Existing Systems?

A common question is whether AR can integrate with existing software. The answer is yes. Modern AR platforms are not built in isolation; they are designed to connect to your operational backbone using APIs (Application Programming Interfaces).

This is where the real value is unlocked. AR can pull live data from your ERP, access service histories from your MES, or display the latest specifications from your PLM. It connects directly to the tools you already use.

The true power of AR is not in replacing your current systems, but in creating a visual window into your existing data streams, making information immediately accessible and useful for your teams on the floor.

How Do We Actually Measure the ROI?

The business case for AR is built on tracking hard numbers and clear metrics that tie directly to your bottom line.

You can measure success by monitoring improvements in these key indicators:

- First-Time Fix Rates: An increase in this metric is a direct sign of greater efficiency and customer satisfaction.

- Assembly Error Reduction: This provides a clear measure of savings from reduced rework and material waste.

- Training Time: Calculate how much faster new hires become fully productive.

- Expert Travel Costs: Track the reduction in your travel budget as you use remote assistance to solve problems.

Focusing on metrics like these provides a solid business case for moving forward with AR adoption.

Ready to see how AR can solve your biggest operational headaches? AIDAR Solutions provides the expert guidance and powerful tools you need to launch a successful AR program. Discover our solutions and let's get started.