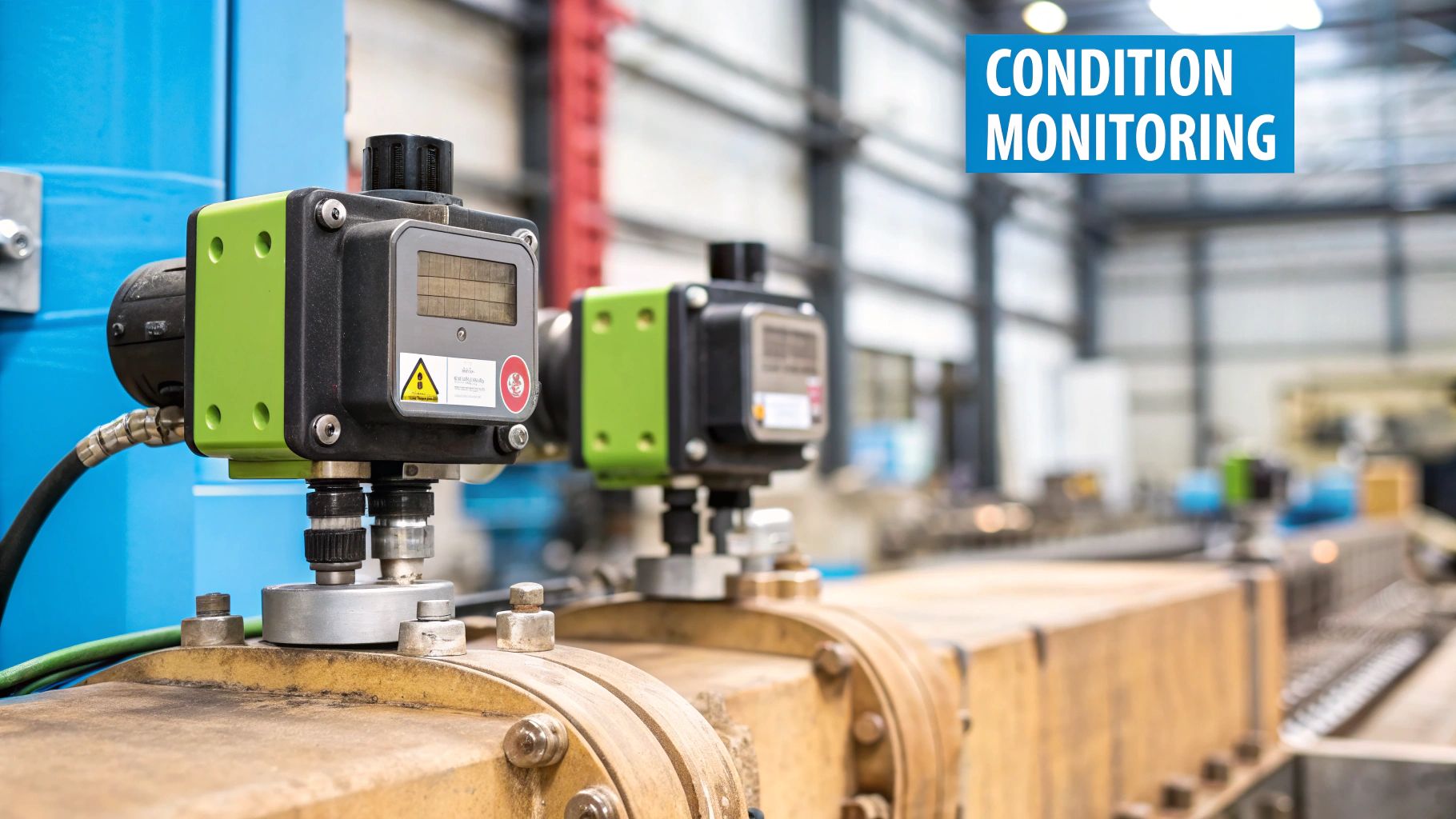

Condition Monitoring & Predictive Maintenance Guide

Consider the difference between your car's engine seizing up on the highway versus receiving a dashboard alert that a specific part requires attention next week. This is the fundamental difference between traditional reactive maintenance and the proactive strategy of condition monitoring and predictive maintenance. It represents a strategic shift from a "fix it when it breaks" mentality to a "prevent it from breaking" approach.

Moving From Reactive Fixes to Proactive Wins

For decades, industrial maintenance was largely reactive. A machine would fail unexpectedly, triggering a scramble to bring it back online. This model is inherently inefficient and costly, leading to unplanned production shutdowns, expensive emergency repairs, and potential safety risks. It operates on a simple but flawed principle: if it isn't broken, don't fix it.

Preventive maintenance, the next evolution, was a step forward. It operates on a fixed schedule, similar to changing a car's oil every 5,000 miles. However, this approach has limitations. It often leads to replacing parts that have significant operational life remaining or, conversely, fails to prevent a failure that occurs just before a scheduled check-up. It is an educated guess that doesn't fully account for actual equipment usage and condition.

To truly understand how these maintenance philosophies stack up, it's helpful to see them side-by-side.

Comparing Maintenance Strategies

| Maintenance Type | Core Principle | Typical Downtime | Cost Efficiency |

|---|---|---|---|

| Reactive | "Fix it when it breaks." | High & Unplanned | Very Low |

| Preventive | "Fix it on a schedule." | Planned, but can be excessive | Moderate |

| Predictive | "Fix it when data says it's needed." | Minimized & Planned | High |

The table clarifies why many organizations are moving towards a more intelligent, data-driven approach. Predictive maintenance is not just an incremental improvement; it is a fundamental change in asset management.

The Strategic Shift to Prediction

Condition monitoring and predictive maintenance introduce a new level of sophistication. Instead of relying on schedules or waiting for breakdowns, this strategy involves monitoring equipment in real time. Sensors are used to track key parameters—such as vibration, temperature, and acoustic signatures—providing a continuous, clear picture of asset health.

This stream of data is what makes prediction possible. Condition monitoring provides the current status of the machine, while predictive maintenance uses that information to forecast future needs.

This isn't just a technical upgrade; it's a completely different business strategy. It turns maintenance from a cost center that just reacts to problems into a value driver that actively boosts reliability, performance, and overall operational excellence.

This proactive approach allows teams to schedule repairs with surgical precision—right when they're needed to prevent both wasteful early replacements and catastrophic failures. It's a data-driven strategy that delivers real, measurable results.

Driving Tangible Business Outcomes

When you can anticipate equipment needs before they become emergencies, the benefits are felt across the entire organization. This foresight translates directly into better efficiency and a healthier bottom line.

Here are a few of the key advantages:

- Slash Operational Downtime: Scheduling maintenance before a failure hits means you can virtually eliminate unplanned shutdowns. Studies have shown this can reduce downtime by 35-45%.

- Lower Repair Costs: It's always cheaper to fix a small issue before it snowballs into a major breakdown. This approach has been shown to cut overall maintenance costs by 25-30%.

- Create a Safer Workplace: A machine that’s well-maintained is a safer machine. By predicting and preventing failures, you also prevent dangerous malfunctions that could put your team at risk.

The industry is taking notice. The global market for condition monitoring systems is on track to more than double, from USD 4.38 billion in 2025 to USD 9.20 billion by 2035. You can dig into more of the numbers and trends on Future Market Insights. This growth in manufacturing, energy, and transportation is a clear sign of just how critical this technology has become. Throughout this guide, we'll break down exactly how you can put this powerful strategy to work.

How Condition Monitoring Hears What Machines Are Saying

To understand a machine's health, one must interpret its operational signals. Condition monitoring is the process of translating the subtle indicators and vital signs of equipment into clear, actionable intelligence. It replaces guesswork with real data to understand an asset's present condition.

This process is analogous to a physician's check-up for critical machinery. Instead of waiting for a total breakdown, this method continuously tracks key performance indicators, offering a clear window into operational well-being. This ongoing assessment is the foundation for any powerful condition monitoring and predictive maintenance strategy.

The primary objective is to acquire the raw data needed to identify potential issues early. By establishing a baseline for normal operation, even the smallest deviation acts as an early warning, flagging an issue long before it becomes a crisis. The goal is simple: catch problems while they are still small, inexpensive, and easy to fix.

Vibration Analysis: The Stethoscope for Machines

One of the most powerful diagnostic tools is vibration analysis. Similar to how a physician uses a stethoscope to listen to a heartbeat, technicians use sensors to monitor the inner workings of rotating equipment like motors, pumps, and gearboxes. Every machine has a unique vibration "signature" during correct operation.

When a component like a bearing begins to wear or a shaft becomes misaligned, it disrupts this signature, creating detectable shifts in vibration. These shifts are often the earliest signs of trouble. Capturing and analyzing this data allows maintenance teams to pinpoint the exact location and nature of a developing fault—such as imbalance, looseness, or bearing wear—before it leads to a catastrophic failure.

Thermal Imaging: Finding Fevers in Your Equipment

Another crucial technique is thermal imaging, also known as thermography. This method uses infrared cameras to visualize heat, allowing technicians to see "fevers" or hot spots that are invisible to the naked eye. In an industrial setting, excess heat is almost always a sign of an anomaly.

This could be friction from a poorly lubricated part, a loose electrical connection creating resistance, or a blocked coolant line.

A routine thermal scan of an electrical control panel might reveal a connection that is 150°F hotter than identical ones next to it. This is a clear indicator of a failing component that could otherwise lead to a fire or an entire system shutdown. This non-contact method is incredibly safe and effective for both electrical and mechanical inspections.

Oil Analysis: A Blood Test for Engines

For equipment with internal combustion engines or large hydraulic systems, oil analysis functions like a blood test. A small sample of lubricant can reveal a tremendous amount about the health of the machine's internal components.

By analyzing the oil for microscopic metal particles, contaminants like dirt or water, or chemical changes in its viscosity, technicians can diagnose a wide range of issues. For example, detecting high levels of iron might point to gear wear, while the presence of coolant could indicate a cracked engine block. This insight allows for targeted repairs before major damage occurs.

Ultrasonic and Acoustic Analysis: Listening for the Unheard

Finally, ultrasonic analysis involves detecting high-frequency sounds that are far beyond the range of human hearing. These sound waves can identify problems like compressed air leaks—a significant source of wasted energy in manufacturing plants—or the early stages of electrical arcing in switchgear.

- Compressed Air Leaks: A small, inaudible leak can cost a facility thousands of dollars a year in wasted energy. Ultrasonic detectors can pinpoint these leaks with remarkable accuracy.

- Electrical Faults: Arcing and tracking in electrical equipment generate unique ultrasonic signatures, providing a warning of imminent failure.

- Bearing Lubrication: These tools can even "hear" when a bearing needs grease, preventing both over-lubrication and under-lubrication.

For large-scale assets or hazardous environments, advanced tools like drones for industrial inspection are increasingly used to gather this critical data safely. While the methods vary, the principle is the same: gather precise data to understand asset health. This data is the essential first step that separates reactive repairs from a truly proactive maintenance strategy.

Turning Data Into Predictions with AI

Collecting real-time equipment data is the first step, but its true value is unlocked when used to forecast future events. This is where artificial intelligence transforms condition monitoring and predictive maintenance from a simple alert system into a strategic forecasting tool. AI doesn't just identify a problem; it anticipates it, shifting the entire maintenance strategy from reactive to proactive.

The process begins with machine learning algorithms analyzing continuous streams of sensor data—vibrations, temperatures, pressures, and more. Over time, the AI learns the unique operational "fingerprint" of each machine, creating a highly detailed baseline of normal performance under various conditions. This digital signature is far more sophisticated than a simple, fixed threshold.

How Anomaly Detection Flags Trouble Early

AI-driven anomaly detection works by recognizing minute deviations from the established operational fingerprint. These subtle changes, such as a slight increase in motor temperature during a specific cycle or a fractional shift in vibration frequency, are often the earliest indicators of a potential failure.

By flagging these tiny irregularities, the AI gives your team a critical head start. It’s the difference between being told "your machine is overheating" and being warned "your machine is showing early signs of stress that will likely lead to overheating in three weeks."

This predictive capability is driving significant market growth. Currently valued at around USD 12.7 billion, the predictive maintenance market is projected to reach USD 80.6 billion by 2033, fueled by AI’s ability to provide this level of advanced, real-time insight.

From Raw Data to Actionable Foresight

Machine learning models do more than just signal that something is wrong; they help answer the critical questions of why it is happening and when it will become a problem. By correlating different data streams, AI can pinpoint the likely root cause and forecast a probable timeline for failure.

This enables maintenance teams to operate with surgical precision. Instead of reacting to emergencies or adhering to a rigid preventive schedule, they can plan interventions for the exact moment they are needed. This approach unlocks a powerful combination of benefits:

- Maximized Asset Life: Parts are replaced based on their actual condition, not a calendar, extending the operational life of each component.

- Optimized Resource Planning: Maintenance can be scheduled during planned downtime, ensuring technicians, tools, and spare parts are ready.

- Drastically Reduced Downtime: By pre-empting failures, organizations avoid the significant costs and disruptions of unplanned shutdowns.

To enhance prediction accuracy, advanced frameworks like Retrieval Augmented Generation (RAG) are continually advancing the capabilities of AI in handling complex industrial data.

Empowering Teams with Predictive Power

Ultimately, integrating AI into a condition monitoring and predictive maintenance program is about empowering personnel. It provides maintenance and reliability engineers with the data-driven foresight to make smarter, more strategic decisions.

This transforms the role of maintenance from a defensive, reactive function to a proactive, value-adding component of the business. By anticipating future events, organizations can keep their most critical assets running reliably, efficiently, and safely, turning maintenance into a true competitive advantage.

Using AR and VR for Smarter Maintenance Workflows

Identifying what needs fixing and when is only half the equation. The execution of maintenance tasks on the factory floor is where immersive technologies like Augmented Reality (AR) and Virtual Reality (VR) are bridging the gap between digital insights and physical action. These tools help technicians complete jobs faster, more safely, and with greater accuracy.

AR and VR are no longer futuristic concepts; they are practical tools delivering significant impact. They serve as the interface connecting the complex data from a condition monitoring and predictive maintenance program directly to the frontline technician. The objective is to deliver the right information to the right person at the precise point of need.

Augmented Reality for On-the-Spot Guidance

Augmented Reality overlays digital information onto a technician's view of the real world, typically through smart glasses or a tablet. This creates an intuitive, context-aware environment where data is no longer confined to a separate screen. Instead of juggling a laptop and tools, a technician can see all necessary information in their direct line of sight.

Consider a technician inspecting a complex pump assembly while wearing AR glasses. They could see:

- Live Data Overlays: Real-time temperature, pressure, or vibration readings displayed directly on the corresponding components.

- Digital Schematics: An interactive 3D model of the machine's internals superimposed onto the physical asset, simplifying part identification and wiring traces.

- Step-by-Step Instructions: Animated guides and checklists appearing in their field of view, guiding them through a complex repair sequentially.

This technology provides technicians with a form of "x-ray vision," allowing them to see the invisible data streams that define a machine’s health. By visualizing the problem directly on the asset, they reduce time spent consulting manuals and significantly lower the risk of error.

A powerful application is remote expert assistance. An on-site technician can share their exact point-of-view with a senior expert located anywhere in the world. The remote expert can then annotate the technician's view with virtual notes and diagrams, guiding them through the repair in real time. This capability can reduce expert travel costs by up to 75% and significantly shorten equipment downtime.

Virtual Reality for Risk-Free Training

While AR enhances the real world, Virtual Reality (VR) creates a fully immersive, simulated environment. For training, VR is transformative. It provides engineers and technicians with a safe, digital space to practice complex or hazardous procedures without real-world consequences. This is particularly effective when using a "digital twin"—a precise virtual replica—of actual machinery.

Within these VR simulations, trainees can:

- Practice High-Risk Repairs: Work on maintenance tasks involving high voltage or hazardous materials with zero physical risk.

- Simulate Rare Failures: Troubleshoot critical failures that are too dangerous or expensive to replicate on live production equipment.

- Learn Through Repetition: Rehearse a procedure multiple times until it becomes second nature, without causing wear and tear on parts or risking damage.

Studies indicate that hands-on virtual training can accelerate employee learning by up to 75% compared to traditional classroom methods. Technicians build muscle memory and confidence in a virtual setting, ensuring they are fully prepared when they step onto the factory floor. You can dive deeper into this shift by checking out our insights on how augmented reality changes maintenance workflows.

By integrating AR and VR, companies are not just refining their maintenance programs; they are building a more connected, skilled, and effective workforce equipped for the demands of modern industry.

Your Roadmap to Implementing Predictive Maintenance

Transitioning to a predictive maintenance strategy is a journey that requires careful planning. The most effective approach is to start small, demonstrate value, and then methodically expand the program across your operations. This roadmap outlines the essential stages for moving from concept to a fully operational system that delivers measurable results.

Adopting this model is less about a single, massive technological overhaul and more about a structured, phased rollout. Following a clear path helps avoid common pitfalls, secure management support, and build a program that provides lasting value.

Phase 1: Identify Critical Assets for a Pilot Program

The first step is not to monitor everything, but to monitor what matters most. Begin with a criticality analysis to identify which pieces of equipment would cause the most significant disruption if they failed unexpectedly. Focus on machines that are central to your production line, have a history of costly breakdowns, or pose a safety risk.

Select two or three high-impact assets for a pilot program. This allows you to demonstrate the value of condition monitoring and predictive maintenance without a large initial investment. A successful pilot provides a compelling business case for broader implementation.

Phase 2: Select and Deploy the Right Technology

Once you have identified what to monitor, the next step is to determine how. This involves selecting the appropriate tools, from the sensors that collect data to the platform that analyzes it.

- Sensor Selection: Match the sensor to the asset's most likely failure modes. For a high-speed motor, vibration sensors are ideal. For an electrical cabinet, thermal imaging is the best choice.

- Data Platform: Choose a platform that can manage the entire data lifecycle: collection, storage, and analysis. Many modern cloud solutions offer pre-built AI models that automate anomaly detection and failure prediction.

- System Integration: This is a critical step. The new platform must integrate with your existing Computerized Maintenance Management System (CMMS). This connection enables the automatic generation of work orders as soon as the system predicts a potential issue.

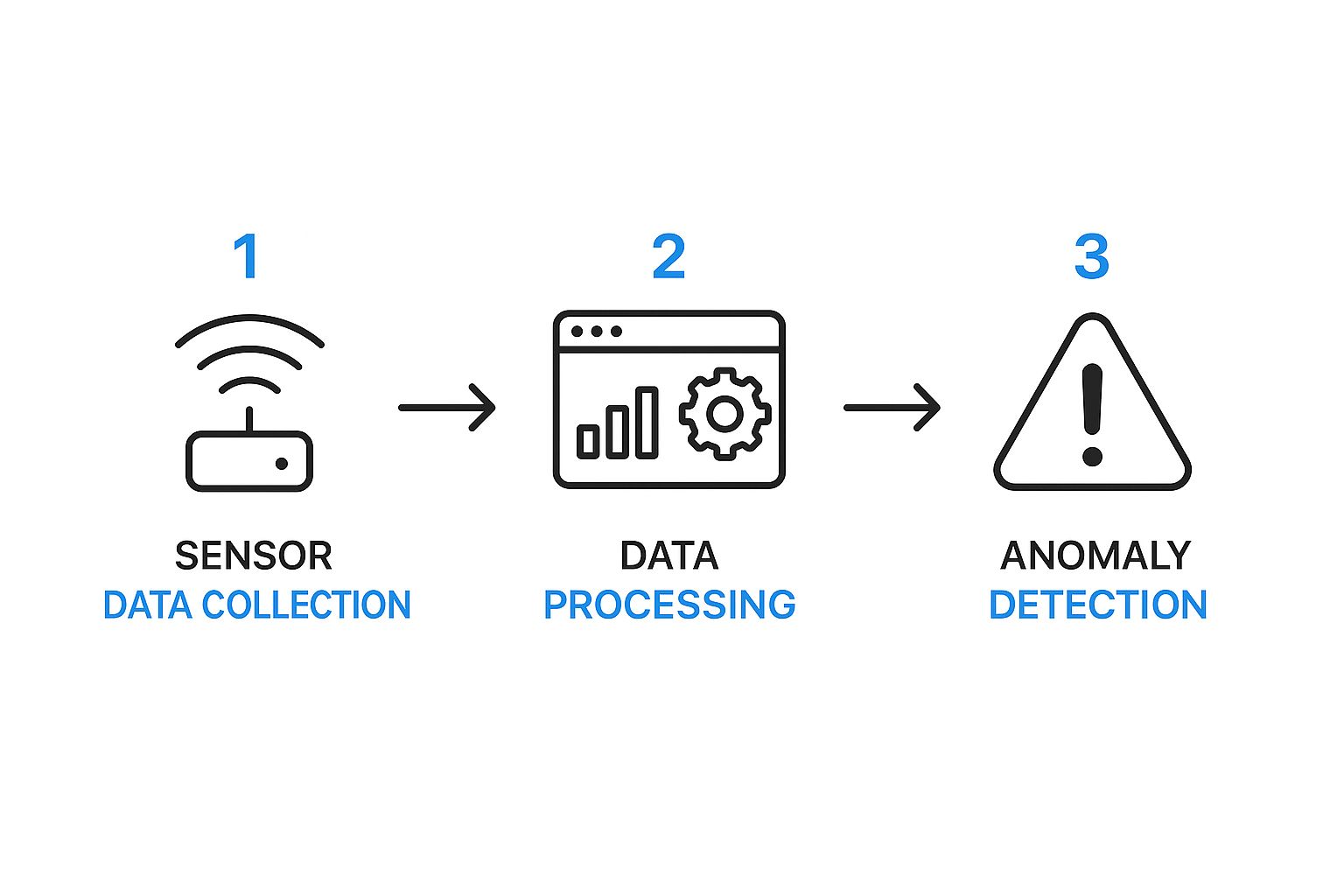

The data flows from sensors for collection, to the platform for processing, where algorithms detect anomalies.

This process transforms a stream of raw machine data into a clear, early warning that maintenance is required.

Phase 3: Establish Protocols and Train Your Team

Technology is only effective if the team knows how to use it. This phase focuses on the human element. You must create clear, documented procedures for responding to alerts. Define who verifies the alert, who creates the work order, and who performs the repair.

Training is equally important. Maintenance technicians, reliability engineers, and plant managers need to understand the 'why' behind the system. This represents a significant cultural shift from reacting to failures to proactively preventing them based on data-driven insights.

A clear troubleshooting process is invaluable when complex problems arise. For more on this, our guide on effective maintenance problem-solving offers valuable strategies. Investing in your team's skills is what transforms the system's insights into real-world action and savings.

Predictive Maintenance Implementation Roadmap

This table summarizes the journey from initial concept to a fully realized program, highlighting the objective, actions, and common challenges for each stage.

| Phase | Key Objective | Primary Action Items | Common Challenge |

|---|---|---|---|

| 1. Pilot Program | Prove the value and secure buy-in with a focused, small-scale project. | Conduct criticality analysis, select 2-3 high-impact assets, define success metrics. | Choosing assets that are too complex or don't fail often enough to show ROI quickly. |

| 2. Technology Deployment | Implement the necessary hardware and software to collect and analyze data. | Select appropriate sensors, choose a data analytics platform, integrate with CMMS. | Getting overwhelmed by technology choices or poor system integration. |

| 3. Process & Training | Build the human systems and skills needed to act on predictive insights. | Develop response protocols, train maintenance teams, create troubleshooting guides. | Team resistance to change or a lack of trust in the new data-driven process. |

| 4. Scale & Optimize | Expand the program to other critical assets and continuously refine the model. | Identify the next group of assets, analyze pilot program results, refine prediction models. | Scaling too quickly without learning from the pilot, leading to diluted results. |

Following a structured roadmap like this helps ensure that your investment in predictive maintenance pays off, not just in the short term, but for years to come.

Common Questions About Predictive Maintenance

Even with a detailed roadmap, practical implementation often raises questions. Addressing these common queries early can ensure team alignment and a smoother transition to a condition monitoring and predictive maintenance program.

What Is the Difference Between Condition Monitoring and Predictive Maintenance?

These two concepts are often confused because they are closely related, but they serve distinct functions.

Think of it as a medical analogy for your machinery. Condition monitoring is the diagnostic process—the act of taking vital signs like temperature, vibration, and pressure. It provides a real-time snapshot of the machine's current health.

Predictive maintenance, in contrast, is the prognosis. It uses the health data gathered through condition monitoring to forecast potential future problems. It answers the critical question: "Given this data, what is likely to fail, and when?"

In short, condition monitoring gathers the real-time data, and predictive maintenance uses that data to see into the future.

How Much Does It Cost to Implement a Program?

The cost of implementation varies significantly depending on the scope of the program. A large-scale deployment is not necessary from the outset.

A small pilot program focused on a few critical machines can be implemented with a modest investment in sensors and a subscription to a cloud-based analytics platform.

A full-scale, facility-wide deployment will require a more substantial budget for hardware, software integration, and comprehensive team training. The recommended approach is to start small, prove the ROI by tracking reductions in downtime and repair costs, and use these successes to justify scaling the program.

Can This Be Applied to Any Type of Equipment?

While it is technically possible to monitor almost any asset, it is not always cost-effective.

The best candidates for predictive maintenance are high-value, mission-critical assets. These are machines where an unexpected failure would halt production, create a safety hazard, or result in a significant financial loss.

It would not be practical to apply this to a low-cost, non-critical pump for which spare parts are readily available. The initial step of any program should be a criticality analysis to identify where condition monitoring and predictive maintenance will deliver the greatest and most immediate return on investment. To understand the underlying technology, it is helpful to grasp the predictive analytics definition that enables these forecasts.

Do I Need Data Scientists on My Team?

Not necessarily, especially in the initial stages. Many modern predictive maintenance platforms are designed for engineers, not data scientists. They feature user-friendly dashboards and pre-built AI models that handle most of the complex analysis.

While a data scientist can be a valuable asset for fine-tuning models or addressing unique challenges as the program matures, your existing maintenance and reliability engineers are fully capable of managing these systems and deriving significant value. The key is to provide them with the right training and demonstrate how to train staff to trust and act on the insights the system provides.

At AIDAR Solutions, we specialize in bridging the gap between digital insights and physical action with immersive AR and VR tools. Our solutions empower technicians to perform their work with greater speed, safety, and precision, turning predictive data into real-world results. Discover how we can enhance your maintenance workflows at https://aidarsolutions.com.