Preventive Maintenance vs Predictive: Which Strategy Wins?

When you stack up preventive vs predictive maintenance, the fundamental difference is straightforward: preventive is all about the calendar, while predictive is all about the machine's actual condition.

Think of preventive maintenance like your car's oil change schedule—you do it every 5,000 miles, no questions asked. Predictive maintenance, on the other hand, is like using sensors to tell you the oil is actually starting to degrade, so you change it at the perfect moment.

Choosing Your Maintenance Strategy

Picking the right strategy isn't about one being "better." It's about finding the right tool for the job. Your choice between preventive and predictive maintenance will come down to your operational goals, how critical your assets are, and the resources you have to work with.

A preventive approach is the traditional, reliable way. It's built on manufacturer recommendations and historical data to set up a regular schedule for checks and replacements. While this routine definitely catches some potential failures, it has its downsides. You might end up doing unnecessary work on perfectly healthy equipment, or worse, miss a surprise issue that pops up between inspections. This is why solid maintenance problem solving is so crucial for teams using this method.

Predictive maintenance is the more dynamic, tech-forward sibling. It uses sensors and data analytics to keep a constant watch on equipment health, letting teams jump in with surgical precision right before something goes wrong. This approach can drastically cut unplanned downtime and squeeze every last drop of life out of your assets, but it does require a bigger upfront investment in technology and the skills to analyze the data.

The real goal of any maintenance strategy is to get out of reactive chaos and into proactive control. Whether you choose preventive or predictive just determines how you get there—through disciplined scheduling or through data-driven foresight.

To make these differences crystal clear, let's break them down in a simple comparison.

Preventive vs Predictive Maintenance At a Glance

Here’s a high-level look at how these two strategies stack up side-by-side.

| Attribute | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Trigger | Time or Usage (e.g., every 6 months) | Asset Condition (e.g., a new vibration is detected) |

| Approach | Proactive, scheduled interventions | Proactive, data-driven interventions |

| Cost | Lower initial cost, but can lead to higher long-term spend | Higher initial investment, but lower long-term spend |

| Technology | Checklists, CMMS, calendars | IoT sensors, AI, machine learning, analytics platforms |

| Best For | Non-critical assets, predictable failure patterns | Critical assets, high cost of failure, complex machinery |

As you can see, the right choice really hinges on the specific asset and its role in your operations. A simple, non-critical pump might do just fine with a preventive plan, but a mission-critical, complex piece of machinery is a perfect candidate for a predictive approach.

The Case for Preventive Maintenance

Preventive maintenance (PM) is built on a simple, time-tested idea: fix it before it breaks. The whole strategy revolves around scheduled tasks triggered by a calendar date, operating hours, or production cycles. It’s a disciplined, systematic approach that gives maintenance teams a clear, predictable playbook.

The main draw of PM is its straightforward nature and predictability. Planning is direct, and it doesn't require the complex technology or heavy upfront investment that more data-intensive strategies demand. For assets with well-understood failure patterns—where you know components tend to wear out at a predictable rate—preventive maintenance is a remarkably effective and cost-efficient method.

Predictable Schedules and Lower Upfront Costs

The structured rhythm of PM makes budgeting and resource allocation so much easier for managers. You can schedule labor, order parts, and plan for downtime well in advance, which keeps operational disruptions to a minimum. This is a huge advantage in any environment where consistency is non-negotiable.

Take a commercial vehicle fleet, for instance. A solid preventive maintenance program is crucial for reducing common problems, like preventing air brake system leaks, which are a frequent cause of inspection violations. Regular, scheduled checks on brakes, tires, and fluids are predictable, manageable, and absolutely essential for safety and compliance.

But this reliance on a fixed schedule is also where the drawbacks start to surface. The core issue in the preventive maintenance vs predictive debate is the risk of doing too much, too soon. Maintenance is often performed on perfectly healthy equipment, wasting labor hours and perfectly good parts. A 2022 report even found that companies often over-maintain their assets, with up to 30% of preventive tasks being done unnecessarily.

Preventive maintenance creates a baseline of reliability through routine care. Its greatest strength is its structure, but its greatest weakness is its inability to account for the actual, real-time condition of an asset.

On the flip side, a fixed schedule can also fail to catch unexpected breakdowns that happen between your planned service intervals. If an asset is suddenly operating under harsher conditions, it might degrade faster than your schedule anticipates, leading to the exact downtime you were trying to avoid. This really highlights the inherent trade-off: PM offers simplicity and order, but it can lack the precision needed for complex or critical machinery where a failure would be catastrophic.

Ultimately, its value is highest for assets where the cost of routine servicing is a drop in the bucket compared to the cost of an unexpected failure.

The Power of Predictive Maintenance

If preventive maintenance is about sticking to a schedule, predictive maintenance (PdM) is about listening to your equipment. It ditches the rigid calendar and instead uses a dynamic, data-driven approach to figure out what needs fixing and when. Instead of servicing equipment "just in case," PdM allows you to act "just in time."

This strategy uses a network of IoT sensors to constantly monitor the real-time health of your machinery. We're talking about tracking everything from vibration and temperature to fluid dynamics. This stream of data is fed into AI and machine learning algorithms that can spot tiny anomalies and forecast potential failures with stunning accuracy. The result? Maintenance only happens when it's truly needed—right before a small problem escalates into a full-blown crisis.

From Data Insights to Actionable Interventions

The real value of predictive maintenance is its ability for turning complex data into clear, actionable marching orders. When an algorithm flags a potential fault, it doesn't just sound a generic alarm. It sends technicians a precise alert detailing the problem and its exact location. This completely removes the guesswork, making maintenance efforts hyper-targeted and efficient.

It’s no surprise that PdM has become the standard in high-stakes industries like aviation and energy, where a single equipment failure can have catastrophic financial and safety consequences. By using technologies like the Internet of Things (IoT) and artificial intelligence (AI), these sectors can keep a constant pulse on asset health and step in only when necessary. This targeted approach cuts down on needless maintenance, squeezes more life out of every asset, and dramatically reduces accidents.

The core difference in the preventive maintenance vs predictive debate is that PdM doesn't just prevent failure; it optimizes asset performance. It's about maximizing the useful life of every component, ensuring you never waste resources on premature replacements.

This precision gets even more powerful when you bring AR and VR into the mix. Imagine a field technician wearing AR glasses that overlay real-time sensor data directly onto a machine, instantly showing them the source of a vibration anomaly. This kind of immersive context leads to faster diagnostics and more accurate repairs, streamlining the entire maintenance workflow from start to finish. To get a better handle on how this works, check out our guide on the synergy between condition monitoring and predictive maintenance.

Of course, jumping into a PdM program isn't a small step. It requires a serious upfront investment in technology and, just as importantly, a cultural shift toward data-driven decision-making. Your team will need new skills to manage and interpret the constant flow of information from sensors. While the initial costs are higher, the long-term ROI—driven by minimized downtime, lower maintenance expenses, and longer asset life—almost always makes a powerful business case.

A Head-to-Head Strategic Comparison

Once you get past the textbook definitions, the real differences between preventive and predictive maintenance show up in your operations and on your balance sheet. Putting them side-by-side reveals some clear trade-offs in technology, cost, and the skills your team needs. It’s not about finding a single "best" strategy, but about picking the right tool for the right asset at the right time.

The most obvious split is in what it takes to get started. Preventive maintenance runs on calendars, checklists, and a solid Computerized Maintenance Management System (CMMS). It's a low-tech, process-first approach that just about any organization can adopt without a massive overhaul.

Predictive maintenance, on the other hand, is a different beast entirely. It’s built on a whole ecosystem of modern tech—IoT sensors to gather data, a reliable network to transmit it, and powerful AI to make sense of it all. This creates a much steeper hill to climb, both in terms of technology and budget.

Technology and Data Demands

The kind of data each strategy needs couldn't be more different. Preventive maintenance works off historical averages and OEM recommendations. This is static, straightforward information that fuels a fixed schedule. The data is simple, easy to manage, and doesn't require any real-time number crunching.

Predictive maintenance is the polar opposite; it thrives on a constant, live feed of dynamic data. It sifts through terabytes of information on vibration, temperature, and acoustics to catch the tiny, almost invisible patterns that signal an upcoming failure. This data-heavy model demands specialized platforms and sharp analytical tools to turn raw numbers into "fix this now" directives.

Preventive maintenance asks, "When is the next scheduled check-up?" Predictive maintenance asks, "What is this asset telling me right now?" This shift from a calendar-based to a condition-based mindset is the core strategic differentiator.

Cost Structure and Return on Investment

From a financial perspective, this is a classic short-term spend versus long-term investment decision. While they operate differently, both aim to boost asset reliability and slash downtime. Preventive maintenance, being time-based, is much easier to get off the ground, with lower upfront costs typically falling between €25,000 and €200,000. You'll often see a return on that investment within 6 to 12 months.

Predictive maintenance, powered by real-time data, requires a much bigger initial investment—somewhere between €50,000 and €500,000. But the payoff is huge: it can cut downtime by 70-75% and reduce maintenance costs by 25-30%, delivering major long-term savings. You can explore more about these financial comparisons to get a complete picture of the costs and benefits involved.

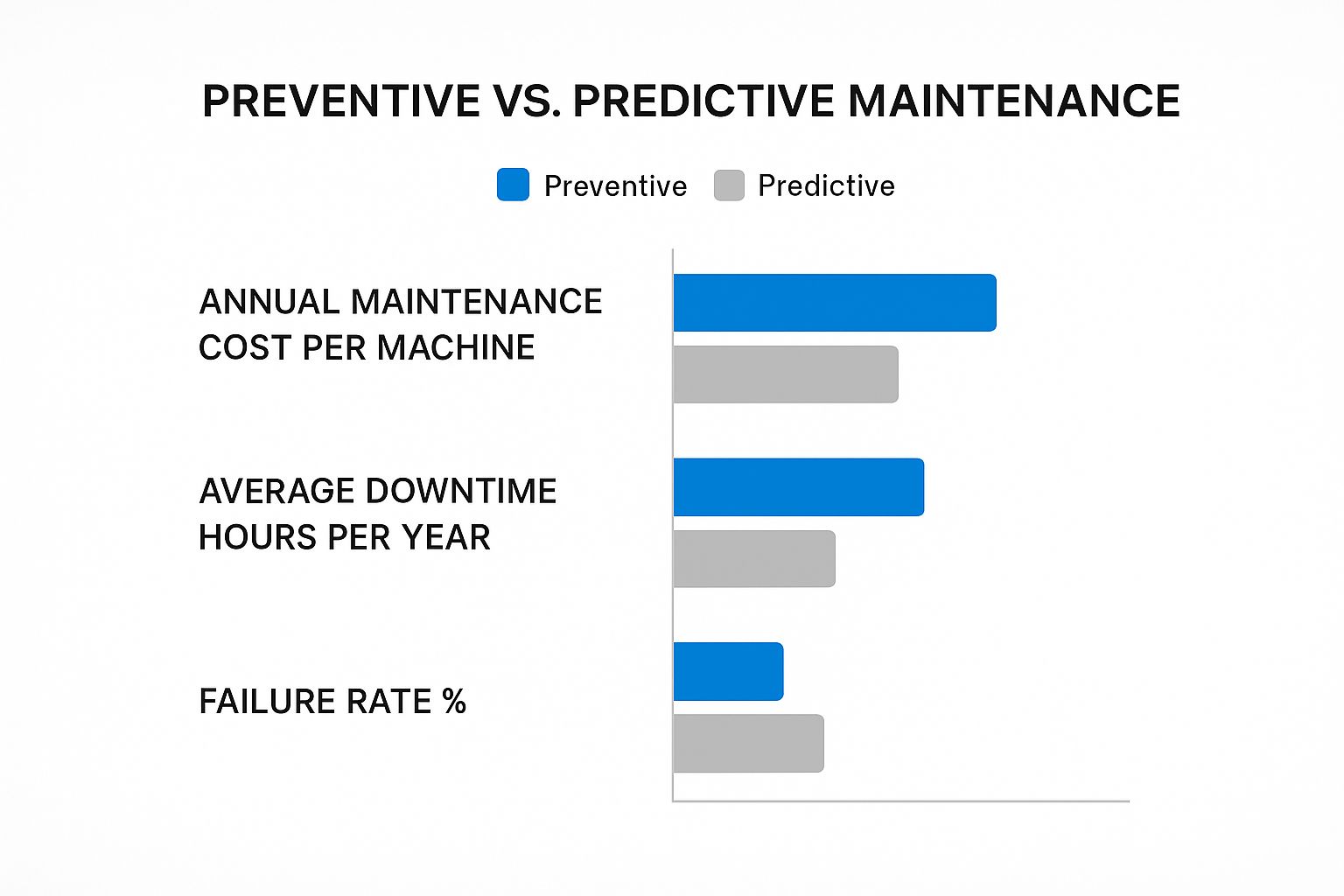

This infographic breaks down the practical results of these different cost structures, comparing the average annual maintenance costs, downtime, and failure rates for each approach.

As the data shows, predictive maintenance asks for more capital upfront, but its knack for stopping failures before they happen leads to dramatically lower operating costs and far less downtime over the long run.

To help clarify the decision-making process, here's a direct comparison of the key factors you'll need to weigh.

Comparative Analysis: Preventive vs. Predictive Maintenance

| Comparison Criteria | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Foundational Approach | Time-based (fixed schedules) | Condition-based (real-time data) |

| Technology Required | CMMS, checklists, basic tools | IoT sensors, AI platforms, data analytics |

| Initial Investment | Lower (€25,000 – €200,000) | Higher (€50,000 – €500,000) |

| ROI Timeline | Faster (6-12 months) | Slower (12-24 months) |

| Data Requirements | Static, historical, OEM specs | Dynamic, real-time sensor data |

| Required Skills | General technicians, planners | Data scientists, reliability engineers |

| Downtime Impact | Reduces unplanned but adds planned downtime | Minimizes both planned & unplanned downtime |

| Best For | Standard assets, predictable wear patterns | Critical, complex machinery, high-failure costs |

This table lays out the fundamental trade-offs. Your choice will ultimately depend on your organization's specific assets, risk tolerance, and long-term strategic goals.

Skill Requirements and Impact on Uptime

Finally, you can't ignore the human element. Preventive maintenance tasks can be handled by general technicians who are trained to follow a set of standardized procedures. The skillset is all about mechanical execution and sticking to the schedule.

Predictive maintenance, however, creates entirely new roles. It requires data analysts and reliability engineers who can navigate complex datasets and make critical calls based on what the algorithms are forecasting. This means a serious investment in either upskilling your current team or hiring new, specialized talent.

The ultimate measure of success, of course, is uptime.

- Preventive Maintenance: It definitely helps reduce surprise breakdowns, but it also introduces planned downtime for service that might not even be necessary.

- Predictive Maintenance: The goal here is to get as close to zero unplanned downtime as possible by scheduling repairs with surgical precision, keeping assets online and productive.

By integrating technologies like AR/VR, teams can push these benefits even further. An AR headset can guide a technician through a complex repair flagged by the predictive system by overlaying data and schematics right onto the machine. This dramatically cuts down on repair time and the chance of human error, boosting the overall effectiveness of a PdM strategy.

Real-World Scenarios and Industry Applications

The real value of any maintenance strategy snaps into focus when you see it in action. In the real-world debate of preventive maintenance vs predictive, there’s no universal right answer. The best choice is always dictated by the asset’s role, the cost of its failure, and how predictably it wears down.

For many businesses, preventive maintenance is the sensible, cost-effective backbone for a huge range of assets. It’s the perfect fit where failure patterns are well-understood and the consequences of downtime are manageable, not catastrophic.

Where Preventive Maintenance Shines

Think about the routine, scheduled jobs that keep a facility ticking over smoothly. These are the sweet spots for a time-based approach, giving you structure and reliability without needing a massive tech investment.

You see it everywhere:

- Commercial HVAC Systems: Annual inspections and filter swaps are based on seasonal use and what the manufacturer recommends. This simple schedule is incredibly effective at preventing common breakdowns.

- Building Maintenance: Scheduled checks on fire safety systems, elevators, and plumbing are non-negotiable for compliance and safety, all following a predictable calendar.

- Fleet Vehicle Servicing: For a delivery fleet, regular oil changes, tire rotations, and brake inspections are straightforward, usage-based tasks that keep trucks on the road and out of the shop unexpectedly.

In these situations, the cost of doing the scheduled work is a tiny fraction of what an unexpected failure would cause in disruption. A preventive plan is just a logical, smart choice.

High-Stakes Environments Demand Predictive Precision

Predictive maintenance, on the other hand, finds its home in high-stakes environments where unplanned downtime can set off a financial and operational nosedive. This is where the investment in sensors and data analytics pays for itself many times over by catching failures before they ever happen. When you're looking at practical implementation, understanding specific Hydratrek service options can be a game-changer for keeping specialized equipment running.

The core idea is simple: the more critical the asset, the stronger the case for predictive maintenance. When failure is not an option, you need the foresight that only real-time data can give you.

This approach is absolutely essential in industries where machinery is complex and the price of failure is astronomical.

- Advanced Manufacturing: Robotics on an automotive assembly line are monitored with vibration analysis to detect the faintest signs of motor or gearbox fatigue. This prevents a line-stopping breakdown that could cost millions per hour.

- Data Centers: Thermal imaging constantly scans servers and electrical panels for hot spots. This helps foresee potential electrical faults that might lead to catastrophic data loss and service outages.

- Heavy Industry: Mining and energy companies rig their critical equipment—like crushers and turbines—with sensor networks. This lets them predict component failures and schedule repairs during planned shutdowns, pushing operational availability to the max.

Technologies like AR and VR take this even further. A technician wearing an AR headset can see real-time thermal data overlaid directly onto a piece of machinery, allowing them to instantly spot an overheating part that the predictive system flagged. This integration turns a complex diagnostic puzzle into a simple "look and fix" task, slashing repair times and minimizing human error. You can see this concept in action in these real-world digital twin examples, which show how virtual models fed by real-time data are completely changing the asset management game.

Building Your Hybrid Maintenance Model

The whole preventive vs. predictive debate often misses the point. It frames the decision as an either-or choice, but the smartest, most cost-effective programs rarely stick to just one strategy. They build a blended, hybrid model that applies the right approach to the right asset. Think of it as creating a maintenance program that’s as dynamic and varied as the equipment it’s meant to protect.

A good hybrid model doesn’t just happen. It’s designed by asking some tough, practical questions about every piece of equipment in your facility. The answers will point you toward the right mix of preventive and predictive tasks, making sure you put your resources where they’ll actually make a difference.

Key Questions to Guide Your Strategy

Before you can strike that balance, you need to get brutally honest about your assets. Start by creating a clear hierarchy based on how critical they are to your operation and how likely they are to fail.

- What’s the real cost of this asset going down? That mission-critical machine that can bring your entire production line to a screeching halt? It demands the highest level of attention. On the other hand, a redundant pump with a spare sitting on the shelf carries a much lower financial risk.

- What’s the equipment's failure profile? Does this asset have a predictable wear-and-tear cycle that fits perfectly with scheduled maintenance? Or are you dealing with a complex system with a dozen unpredictable ways it could fail, making continuous monitoring a necessity?

- Do we actually have the team for a PdM rollout? Kicking off a predictive maintenance program takes more than just cool tech; it requires the right skills. You need to assess if your team has the data analysis chops to make sense of it all, or if you need to budget for training and maybe even a new hire. Answering this honestly keeps you from sinking money into a system you can’t fully use.

A hybrid model is the most pragmatic solution for most organizations. It recognizes that not all assets are created equal and that your maintenance budget is best spent protecting your most valuable and vulnerable equipment with the most advanced tools.

Once you have these answers, you can start sorting your assets into different strategic tiers. This asset-first perspective is the bedrock of any intelligent, cost-effective maintenance program.

Crafting a Pragmatic and Resilient Program

The recommendation here is simple and practical: apply cost-effective preventive maintenance to your less critical assets and strategically deploy predictive maintenance for the high-value, can’t-fail equipment. This tiered approach creates a system that’s resilient, efficient, and financially responsible.

- Tier 1 Critical Assets: For your most important machinery—the stuff that directly impacts revenue and safety—invest in a robust predictive maintenance program. Use IoT sensors and AI to monitor its health in real time, catching problems long before they cause a catastrophic shutdown.

- Tier 2 Important Assets: These are the assets that matter but won’t stop production entirely if they go down. A rigorous preventive maintenance schedule, maybe beefed up with periodic condition monitoring (like quarterly vibration analysis), is usually more than enough.

- Tier 3 Non-Critical Assets: For low-risk, easily replaceable equipment, a basic preventive maintenance checklist or even a run-to-failure approach might be the most economical choice. There’s no sense in over-engineering it.

This layered strategy lets you get the most out of every dollar without gambling on reliability. You get the powerful foresight of predictive maintenance where it counts and the simple, structured security of preventive maintenance everywhere else. This balanced approach is significantly enhanced with modern tools. For example, augmented reality for maintenance empowers technicians to execute both predictive and preventive tasks with greater speed and accuracy by delivering critical information directly into their line of sight.

At AIDAR Solutions, we specialize in creating immersive AR and VR solutions that enhance maintenance workflows, reduce downtime, and accelerate technician training. See how our technology can help you build a smarter, more efficient maintenance program by visiting https://aidarsolutions.com.