Augmented Reality Repair: Boost Industrial Maintenance Efficiency

Augmented reality repair is no longer a concept of the future; it is a practical tool actively solving critical business challenges on the factory floor today. The technology overlays digital information—like 3D diagrams, live data, or step-by-step instructions—directly onto a technician's view of the equipment. It provides immediate, on-the-job expertise for every task.

The True Impact of Augmented Reality on Maintenance

Moving beyond the hype, augmented reality repair is delivering real, measurable value. Companies have advanced past pilot programs and are now integrating AR to tackle persistent operational challenges, from an aging workforce to the high cost of equipment downtime.

At its core, the value proposition is straightforward: AR empowers technicians with the exact information they need, precisely when they need it. It transforms a complex, multi-step procedure into a manageable, guided workflow. Instead of searching through a paper manual or consulting a senior expert, a technician can use a tablet or smart glasses to see exactly which part to adjust or which component to connect.

Closing the Skills Gap

One of the primary drivers for AR adoption is the widening skills gap. As experienced technicians approach retirement, the institutional knowledge they have accumulated over decades is at risk of being lost. Augmented reality offers a direct solution to this challenge.

AR acts as a digital mentor, capturing the expertise of seasoned professionals and converting it into interactive, on-the-job training guides. This enables less experienced team members to perform complex tasks correctly and safely, often on their first attempt. The learning curve is significantly reduced, and new hires become productive much faster. For more information, explore the benefits of augmented reality for maintenance.

Driving Measurable Performance Gains

The business case for AR repair is built on tangible improvements to key performance indicators (KPIs). When this technology is implemented, it has a direct and positive impact on the bottom line.

Key benefits include:

- Reduced Mean Time to Repair (MTTR): With instant access to correct procedures and remote expert support, technicians diagnose and resolve issues faster, getting critical machinery back online with minimal delay.

- Higher First-Time Fix Rates: Step-by-step visual guidance minimizes guesswork, reducing human error and increasing the likelihood that a repair is completed correctly the first time. This cuts down on costly repeat visits.

- Lowered Travel Costs: A senior expert can visually guide an on-site technician from any location in the world, eliminating the travel expenses and delays associated with dispatching a specialist to a remote site.

The core value of AR in a repair context is its ability to deliver the right information to the right person at the exact moment of need. This simple principle unlocks significant gains in productivity and accuracy.

Market growth reflects this value. The global AR market is projected to reach approximately USD 149.57 billion in 2025 and is on track to grow to USD 2,804.82 billion by 2034, representing a compound annual growth rate of about 38.5%. This demonstrates how vital the technology is becoming across industries.

The impact of AR is amplified when integrated with other smart technologies, such as machine learning for predictive maintenance. A system can flag a potential failure before it occurs, and AR can then guide a technician through the preventive fix. This facilitates a shift from a reactive to a proactive maintenance strategy—a key element in the future of industrial efficiency.

How to Build Your AR Integration Strategy

A successful augmented reality repair program is built on a solid strategy, not just technology. Without a clear plan, even the most promising tools can go unused. The key is to move beyond experimentation and build a practical framework that targets high-impact problems and establishes a foundation for long-term success.

The most effective approach is to start small and aim for a measurable win. Instead of a large-scale, company-wide rollout, identify one specific, recurring problem that is currently costing time and money. A targeted pilot project allows you to prove the value of augmented reality repair in a controlled environment, making it easier to gain buy-in for future expansion.

Identify Your Highest-Impact Use Cases

First, identify the operational pain points where AR can make an immediate, tangible difference. It is a common mistake to start with the technology and then search for a problem. Instead, start with the problem. Ask your team to identify the biggest bottlenecks in current maintenance and repair workflows.

Opportunities are often found in a few key areas:

- Complex Assembly or Disassembly: For machinery requiring intricate, multi-step procedures, AR can overlay digital instructions directly onto the equipment, reducing errors and accelerating task completion.

- Remote Equipment Diagnostics: If you frequently send senior experts to remote sites for troubleshooting, a remote assistance AR solution can cut associated travel costs by 75% or more, delivering immediate and significant savings.

- New Hire Onboarding and Training: AR can function as a digital mentor, guiding new technicians through their initial repairs. This shortens their learning curve and helps them achieve full productivity in record time.

The most successful AR strategies share a common trait: they focus on solving a single, high-value problem first. A quick win from a well-defined pilot project builds momentum and provides a powerful business case for leadership.

Choosing the right pilot is crucial. It should address a common issue with clear, quantifiable metrics for success. This focus ensures your initial investment delivers a demonstrable return.

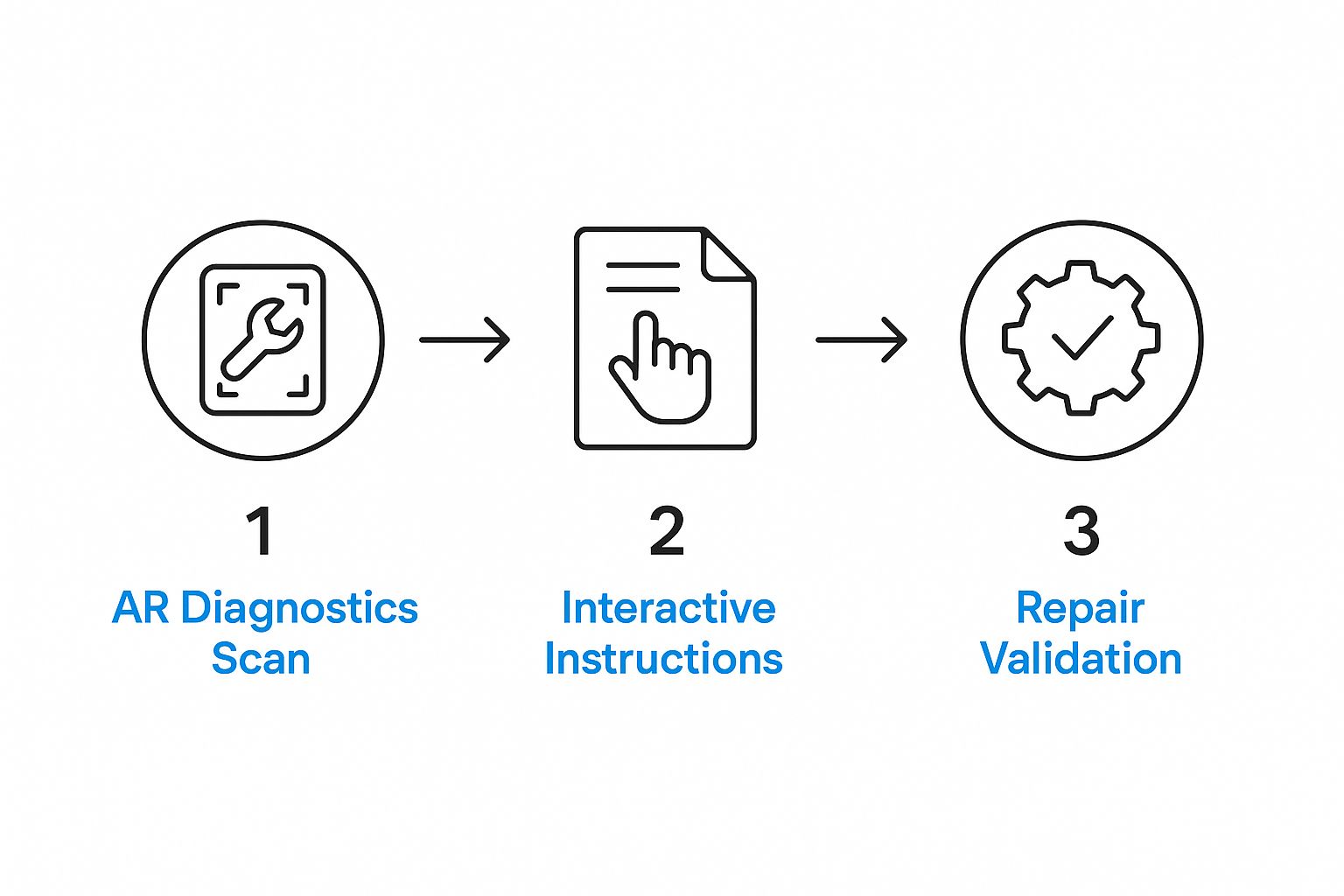

This flow illustrates the core augmented reality repair process, from issue identification to final confirmation of the fix.

As shown, AR streamlines the entire workflow by providing guided diagnostics, interactive instructions, and a final validation step to ensure quality control.

Define What Success Looks Like

Once a use case has been selected, you must define what a successful outcome looks like. Vague goals like "improving efficiency" are insufficient. Your objectives must be specific, measurable, achievable, relevant, and time-bound (SMART).

For instance, set a precise target. Is the main objective to reduce expert travel costs by 50% in the next six months? Or perhaps you are aiming to increase your first-time fix rate by 15% on a specific piece of equipment within one quarter. Tying your AR implementation to concrete business KPIs is essential to proving its value.

This clarity serves two purposes: it helps you select the right AR solution for the job and gives you a clear benchmark for measuring your return on investment. It transforms the project from a technology experiment into a strategic business initiative.

Assemble Your Project Team and Timeline

A successful deployment is not just an IT project; it requires a dedicated, cross-functional team with champions from across the business.

Key team members should include:

- An Operations Lead: This is your on-the-ground contact—a maintenance manager or plant supervisor who deeply understands daily workflows and can identify the best use cases.

- An IT Specialist: They will handle the technical aspects, from hardware setup and software integration to ensuring network capability.

- Technician Champions: Involving a few frontline technicians from day one is critical. Their feedback is invaluable for ensuring the tool is practical and user-friendly. They will become your most effective advocates.

With your team in place, map out a realistic timeline. A typical pilot project might take three to six months, from initial planning to final review. Break it down into clear phases: planning, vendor selection, implementation and training, execution, and results analysis. This keeps the project on track and ensures all stakeholders understand expectations and deadlines.

Choosing the Right AR Hardware and Software

Navigating the AR hardware and software market can feel overwhelming. The market is filled with options, and every vendor promotes their product as the ideal solution. The key is to focus on what best fits your operation, budget, and long-term vision for augmented reality repair.

Consider your hardware choice as the physical link between your technicians and the digital information they need. The goal is not to find the "best" device on the market but to find the best fit for your unique work environment and the specific tasks your team performs daily.

Selecting the Right Hardware for the Job

The hardware discussion typically revolves around a few key categories, each with distinct advantages for different repair scenarios. There is no one-size-fits-all answer; you must consider how and where your technicians perform their work.

Hands-Free Smart Glasses

Devices like the Microsoft HoloLens or RealWear Navigator are designed for demanding industrial environments. Their primary benefit is allowing technicians to keep their hands on their tools, not on a screen. This is a significant advantage for any task requiring two hands, such as adjusting delicate components or working in confined spaces.

- Best for: Complex, hands-on repairs where safety requires full situational awareness and the use of both hands.

- Consideration: These devices represent a larger upfront investment and may require more dedicated training for team adoption.

Tablets and Smartphones

Most technicians already own a smartphone, making this the most accessible entry point for AR. Using familiar tablets or phones for digital work instructions or remote expert calls significantly lowers the initial barrier to entry.

- Best for: Diagnostic work, referencing schematics, or situations where a technician can easily spare a hand to hold a device.

- Consideration: They are not truly hands-free, which can be a significant limitation—and a potential safety hazard—in many repair situations.

Your hardware choice should be dictated by the technician’s workflow, not the other way around. If the job requires two hands, hands-free smart glasses are the only practical solution. For less intensive tasks, the accessibility of tablets can be a great starting point.

The technology is advancing rapidly. Innovations like microLED displays with pixel densities over 6,000 PPI are on the horizon and expected to be standard by 2026. Combined with the rollout of 5G for seamless data streaming, the capabilities of augmented reality repair will only continue to grow. Exploring global market trends can provide a clearer picture of future developments.

Must-Have AR Software Features

If hardware is the body, software is the brain. The platform you choose determines your system's capabilities and how smoothly it integrates with your existing workflows. You need a solution built for practicality, not just impressive demonstrations.

A robust software platform should deliver a core set of features designed to make a technician's job less stressful and more effective.

Key features to look for include:

- Seamless Remote Assistance: This is the core of AR repair. An expert in an office needs to see exactly what the technician in the field sees and provide real-time guidance. The connection must be stable, with low latency and clear communication.

- Intuitive Digital Work Instruction Authoring: The system must be usable by non-developers. Your subject matter experts should be able to create step-by-step digital guides easily. Look for a no-code or low-code authoring tool that allows you to convert institutional knowledge into standardized procedures.

- Robust System Integration: Your AR platform must integrate with other systems, such as your CMMS or ERP. Proper integration means a work order can automatically trigger an AR workflow, and upon completion, the data flows back into your system of record, creating a unified loop.

Selecting the right hardware and software is a strategic decision that will directly influence the success of your augmented reality initiative. By focusing on real-world use cases and prioritizing features that assist your technicians, you can build a solution that delivers measurable value from day one.

Getting Your Technicians On Board with AR

New technology is only effective if people use it. A successful augmented reality repair program depends less on advanced hardware and more on the human element. The true measure of success is when your technicians not only accept the new tools but fully embrace them.

The goal is to introduce AR not as another top-down mandate, but as a powerful ally that makes their jobs easier, safer, and faster. Once a technician sees the technology as the most efficient way to solve a difficult problem, initial skepticism will diminish.

From "Not Another Gadget" to "How Did I Work Without This?"

It is normal for seasoned technicians to be wary of new tools. They have established methods that have served them well. Overcoming this initial hesitation requires demonstrating a clear and immediate benefit from day one.

Focus training on the real-world challenges they face daily rather than on technical specifications. Select a common, frustrating repair and show them how augmented reality repair offers a more efficient solution.

- Show, Don't Just Tell: Allow them to experience a remote expert call immediately. When they see for themselves how quickly they can get a senior specialist’s eyes on a problem—without delays—the value becomes clear.

- Pick a "Hero" Use Case: Focus the first training session on a single, high-impact workflow, such as a notoriously difficult diagnostic procedure or a task that frequently requires a second opinion. A quick, decisive win builds confidence.

- Find Your Champion: Identify a well-respected technician to be an early adopter. Peer-to-peer endorsement is far more powerful than a management directive. When others see a trusted colleague using the tool successfully, they are more likely to adopt it.

Building Workflows That Actually Flow

The effectiveness of an AR system lies in its digital work instructions. These step-by-step guides provide your frontline team with expert-level knowledge. If these instructions are clunky or confusing, technicians will revert to their old methods.

Creating intuitive workflows involves translating dense technical manuals into simple, visual, and actionable steps. Your subject matter experts should be able to build these guides without needing coding skills. The best AR platforms are designed for this, allowing senior technicians to simply "record" a procedure and add clear instructions, photos, and 3D guides.

An augmented reality tool should reduce a technician's cognitive load, not add to it. The system needs to handle the complexity, so the user can focus completely on the physical task. When they barely notice the technology is even there, you know you've succeeded.

Setting Clear Rules for Collaboration

Remote assistance is one of the most powerful features of any augmented reality repair solution, but it requires clear guidelines to be effective. Without a defined process, these calls can become disorganized and inefficient.

Establish a simple, standard procedure for initiating and conducting remote support sessions.

- Define When to Call for Help: Create a clear trigger for requesting remote support, such as after 15 minutes of troubleshooting or when a specific error code appears. This prevents unnecessary calls while ensuring experts are engaged when needed.

- Standardize How You Talk: Coach both the on-site technician and the remote expert on effective communication. The person in the field should clearly state the problem and what they have already tried. The expert should provide concise, direct guidance.

- Create a Feedback Loop: After each call, gather quick feedback from both participants. Was the connection stable? Were the instructions clear? This continuous improvement cycle helps refine the process over time.

Ultimately, you must track how well your training translates to real-world performance. For a deeper look into this critical step, review our guide on how to measure training effectiveness to ensure your program is delivering results. By focusing on the user experience and demonstrating tangible benefits, you can transform an AR rollout from a technology project into an operational game-changer.

Measuring Success and Scaling Your AR Program

You have completed a successful pilot, which is a significant first step. However, transforming that initial success into a company-wide asset requires demonstrating its value with hard data. To gain the necessary buy-in for expansion, you must move beyond anecdotal wins and focus on concrete metrics that are meaningful to the business.

Your goal is to build a powerful business case showing a clear return on investment (ROI). This data not only justifies the pilot but also supports the argument for scaling the augmented reality repair program to other departments or facilities. Without this evidence, even the most effective tool can fail to gain traction.

Key Performance Indicators to Track

To build that business case, you must track the right key performance indicators (KPIs). These metrics should directly correlate with the operational pain points you initially set out to solve. Vague claims of "improved efficiency" are insufficient—you need numbers that resonate with business leaders.

Focus your data collection on these high-impact areas:

- First-Time Fix Rate (FTFR): This is one of the most powerful metrics to track. A rising FTFR means fewer repeat technician visits, less wasted material, and higher asset availability. Track this for specific equipment before and after implementing AR to show a clear improvement.

- Mean Time to Repair (MTTR): How long does it take your team to diagnose and complete a repair? With AR's guided workflows and instant access to experts, this number should decrease significantly, directly translating to less downtime.

- Expert Travel Costs: This is often the easiest win to quantify and one of the most compelling. Calculate the savings on flights, hotels, and per diems by using remote assistance instead of sending a specialist to a site. A 75% reduction in travel is a realistic and persuasive figure.

- Technician Training Time: How quickly can a new hire become proficient on complex machinery? Compare the onboarding time for technicians using AR versus traditional manuals and shadowing. Faster ramp-up time is a direct productivity gain.

The strongest business cases are built on a foundation of clear, quantifiable data. When you can present findings like, "Our pilot program reduced machine downtime by 22% and cut expert travel by $50,000 in three months," you are no longer discussing technology—you are discussing profit.

Collecting this data requires a disciplined approach. Use your CMMS or work order system to log these metrics consistently. This historical data provides the baseline needed to demonstrate the true impact of your augmented reality repair solution. For teams looking to improve their diagnostic skills, understanding the core principles of effective maintenance problem solving is also a critical component.

From Successful Pilot to Enterprise-Wide Asset

With proven results from your pilot, the next step is to develop a strategic plan for scaling. A haphazard expansion can dilute the impact and create new challenges. A structured approach ensures that each new deployment builds on the success of the last.

Market trends support this strategy. The AR remote maintenance tools market, a core component of augmented reality repair, is projected to grow from USD 2.8 billion in 2025 to USD 6.4 billion by 2035. This growth highlights the immense value companies are finding in remote expert guidance, which reduces travel costs and accelerates critical repairs in sectors like industrial machinery and energy. You can explore more insights on these AR remote maintenance tool market trends.

To scale effectively, standardize your approach. Document the best practices and workflows developed during the pilot. This creates a repeatable model that can be deployed at other sites with predictable, positive results.

Next, identify the highest-impact use cases by analyzing maintenance data from across the organization. Look for the same bottlenecks you solved in the pilot—high MTTR, low FTFR, frequent expert travel—and prioritize those areas for the next phase of your rollout. This data-driven expansion is how you transform your AR program from a single-point solution into a strategic, company-wide competitive advantage.

Got Questions About Augmented Reality Repair? We've Got Answers

When exploring augmented reality for your repair teams, several key questions typically arise. Answering these practical, real-world concerns is the first step toward making an informed decision and ensuring a successful rollout.

Let's address the operational questions that technicians and leaders often ask before committing to a new way of working.

How Hard Is It for Technicians to Actually Use This Stuff?

This is a primary concern: "What is the learning curve for my team?" Modern AR platforms are designed to be intuitive. The objective is to empower technicians, not burden them with complicated technology.

Most solutions operate on familiar hardware, like tablets, or use simple voice commands for hands-free smart glasses. While a brief orientation is necessary, technicians typically adapt very quickly. The system is designed to deliver expertise through guided instructions, allowing the user to focus on the physical task rather than on operating the tool.

A well-designed AR repair system should feel almost invisible. It's there to reduce cognitive load, seamlessly guiding the technician to the fix without adding another layer of complexity to their job.

Can AR Solutions Play Nicely with Our Current Software?

Yes. Integration is not just a feature; it is a fundamental requirement for any enterprise-grade AR platform. Leading solutions are built to connect with existing systems, whether it's a Computerized Maintenance Management System (CMMS) or an Enterprise Resource Planning (ERP) tool.

This is critical to prevent the AR tool from becoming an isolated data silo. With proper integration, information flows automatically and smoothly between systems. For instance:

- A new work order in your CMMS can instantly trigger the correct AR-guided workflow for the assigned technician.

- When the repair is complete, critical data—such as completion time, technician notes, and photos—is automatically pushed back into the original work order.

- This creates a closed-loop system that enriches the data in both your AR platform and your maintenance software.

This connectivity makes your augmented reality repair tool an amplifier for your existing software, not a replacement.

What’s the Real Return on Investment Here?

While the exact ROI depends on your specific operations, many organizations see a positive return within 12 to 18 months. The most immediate payback often comes from reducing expert travel costs through remote assistance, which is easy to measure.

However, the largest long-term savings accumulate from other improvements. Consider the reduction in equipment downtime, which directly impacts production output. Or consider higher first-time fix rates, which cut down on wasted labor and materials from repeat visits. For a deeper look at the numbers, our guide on augmented reality for training shows how AR also accelerates onboarding, further contributing to your bottom line.

Our recommendation is to start with a focused pilot project. Target a high-frequency, high-cost problem you are currently facing. This approach allows you to demonstrate a clear and rapid ROI, building a solid business case for future expansion. Start small, prove the value, and build the momentum to transform your entire maintenance operation.

Ready to see how AIDAR Solutions can cut your service times and boost technician efficiency? Explore our immersive AR and VR solutions and book a demo to build your custom action plan.