Augmented Reality Maintenance Explained

Augmented reality maintenance is a technology that overlays digital information—such as step-by-step instructions, 3D diagrams, or real-time performance data—directly onto a technician's real-world view of equipment. This approach provides interactive, hands-free guidance precisely when and where it is needed most.

Seeing Maintenance in a New Light

Consider a field technician arriving at a site with a complex piece of industrial equipment. Instead of referencing a bulky manual or consulting a senior expert by phone, the technician puts on a pair of smart glasses.

Instantly, their view of the machine is enhanced with digital guides that highlight the exact components needing attention and display animated procedures for the repair. This is the core of augmented reality maintenance. It bridges the gap between digital knowledge and the physical reality of the factory floor, functioning like a digital mentor that guides technicians with confidence.

From Reactive to Proactive Operations

Traditional maintenance has often been reactive, relying on paper-based instructions and the institutional knowledge of a few seasoned experts. This method can lead to costly downtime and errors. AR technology transforms this model by equipping every technician with the data they need, directly in their line of sight.

- Visual Guidance: Overlays animated, step-by-step instructions directly onto the equipment.

- Data on Demand: Displays real-time sensor data, schematics, and work orders, all hands-free.

- Expert Collaboration: Enables remote experts to see exactly what the on-site technician sees and provide live guidance.

By putting information into context and placing it directly in a technician’s view, AR reduces their mental workload. It allows them to focus completely on the task at hand, which improves both their speed and accuracy.

This technology transforms maintenance from a reactive process into a precise, data-driven operation. It effectively turns every team member into a more capable and efficient problem-solver.

The result is a more resilient and productive workforce, prepared to tackle challenges with greater skill and less delay. This translates to fewer operational disruptions and a healthier bottom line.

The Business Case for AR-Powered Maintenance

It is no surprise that industrial leaders are shifting more of their maintenance budgets toward augmented reality. This is not about adopting the latest technology trend; it is a strategic move driven by compelling financial and operational benefits that offer a clear return on investment.

At its core, augmented reality maintenance converts a traditional cost center into a powerful tool for building industrial resilience.

This shift directly addresses problems that have challenged the industry for decades. Every minute a critical machine is offline, revenue is lost. Simultaneously, a simple human error during a complex repair can cause safety incidents, require additional repair work, and waste expensive parts. AR tackles these issues by giving technicians the exact information they need, precisely when and where they need it.

Boosting First-Time Fix Rates

One of the most significant benefits is a dramatic increase in first-time fix rates. When a technician arrives at a job with an AR device, they have immediate access to schematics, repair histories, and visual step-by-step guides—all overlaid directly onto the physical equipment.

This immediate access to information eliminates guesswork. Instead of spending hours diagnosing the problem, technicians can pinpoint the root cause and complete the repair correctly on the first attempt. This is a critical advantage as machinery becomes increasingly complex.

By delivering real-time, contextual guidance, augmented reality gives technicians the power to solve problems faster and more accurately. This directly slashes costly machine downtime and eliminates the need for repeat service calls.

Improving first-time fix rates also strengthens an entire maintenance strategy. To understand how this fits into a broader context, you can learn more about the differences between predictive vs preventive maintenance in our detailed guide.

Closing the Skills Gap with On-Demand Expertise

The industrial sector is also facing a significant skills gap, with seasoned experts retiring and an insufficient number of new technicians to replace them. AR offers a practical solution by acting as a virtual mentor for the next generation of talent.

A junior technician can use an AR headset to connect instantly with a senior expert located anywhere in the world. That expert sees exactly what the person on-site sees, allowing them to provide real-time instructions, draw annotations in the technician's field of view, and guide them through the most complex procedures. This on-demand support system accelerates learning and builds confidence.

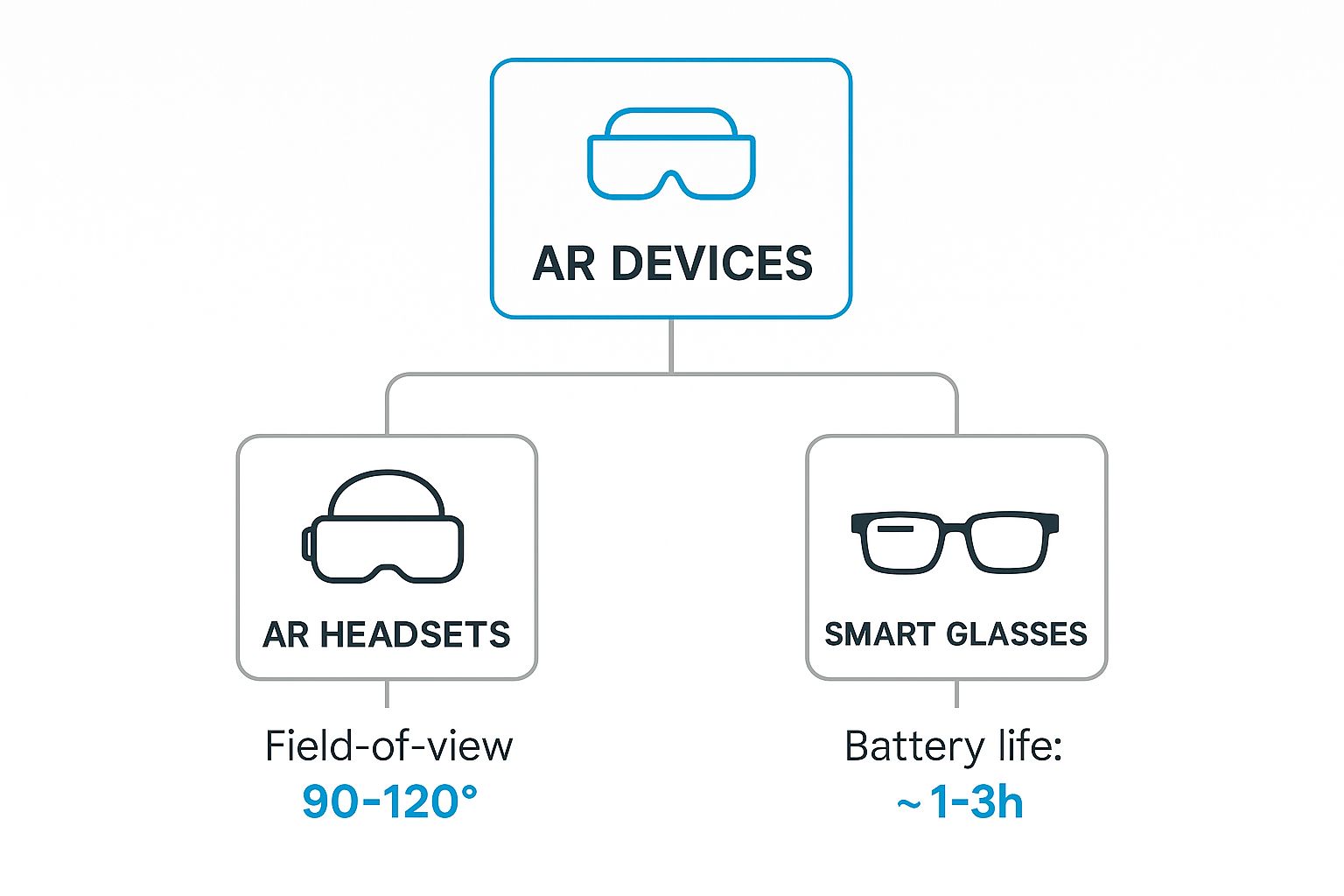

The industrial and manufacturing sectors have become primary adopters of AR, driven by the need for higher productivity. This is supported by market data, which shows that hardware like smart glasses accounted for over 58% of the market, highlighting the crucial role of these devices for maintenance professionals.

Companies using AR report reductions in maintenance times by up to 40% and error rates by approximately 25%. These figures demonstrate that AR is a strategic investment that delivers tangible returns.

Key Capabilities of AR Maintenance Platforms

To fully appreciate the power of augmented reality maintenance, one must look beyond the hardware to the capabilities of the platforms themselves. These are not merely digital displays; they are intelligent support systems designed around core functions that simplify complex jobs and empower technicians on the ground.

Each function is built to solve a specific, real-world challenge, from connecting with an expert instantly to visualizing a machine's inner workings without physical disassembly.

First, let's consider the hardware that enables these capabilities.

As shown, there is no one-size-fits-all solution. AR headsets are well-suited for deeply immersive, complex jobs where a wide field of view is critical. In contrast, smart glasses are designed for mobility and extended use, making them ideal for technicians who require a lightweight device with all-day battery life.

Remote Assistance and Expert Guidance

Imagine a junior technician facing a critical equipment failure while the nearest senior expert is hundreds of miles away. Previously, this meant waiting for assistance to arrive. With AR, that delay is eliminated. The technician simply dons a device and streams their exact point-of-view to the expert in real time.

This is the essence of remote assistance. The off-site expert sees the problem as if they were physically present. They can then draw, place digital notes, or overlay diagrams directly onto the technician's view, guiding them through the repair. A high-stakes problem becomes a collaborative, guided solution, reducing travel costs and bringing machines back online in a fraction of the time. You can explore the benefits of augmented reality remote assistance in field service to see how this changes operations.

This capability essentially teleports your most skilled experts to any job site in the world, instantly. It ensures that every technician, regardless of their experience level, has access to the best possible support when they need it most.

Digital Step-by-Step Work Instructions

Another transformative feature is the ability to project digital work instructions directly onto equipment. This creates an interactive, intelligent manual that comes to life where it is needed most.

Instead of consulting a paper manual or looking back and forth at a tablet, technicians see clear, animated steps overlaid on the machine they are servicing.

- Guided Procedures: Arrows can point to the exact bolt that needs turning, while animations show the correct method for removing a component.

- Contextual Data: Information such as torque specifications or live sensor readings can appear next to the relevant component.

- Task Verification: The system can confirm a step was completed correctly before allowing the technician to proceed, enhancing safety and compliance.

Interactive 3D Visualization

Finally, AR maintenance platforms allow technicians to perform a virtual teardown of a machine. By projecting a detailed 3D model over the physical equipment, they can peel back layers and explore internal components without touching the asset.

This is an invaluable tool for training and complex diagnostic work. A technician can see how different parts fit together and function, helping them build a deeper understanding of the system. It enables them to identify root causes of failures that would otherwise be hidden from view.

To summarize, here is a quick overview of the core functionalities found in most AR maintenance solutions and their direct impact on daily operations.

Key Features of Augmented Reality Maintenance Platforms

| AR Capability | Primary Function | Key Operational Benefit |

|---|---|---|

| Remote Expert Assistance | Live video/audio stream with shared annotations. | Reduces travel costs and downtime by providing instant expert access. |

| Digital Workflows | Overlays step-by-step instructions onto equipment. | Improves first-time fix rates and ensures procedural compliance. |

| 3D Model Visualization | Projects digital twins over physical assets. | Accelerates training and simplifies complex diagnostic procedures. |

| Knowledge Capture | Records expert-led sessions for future use. | Builds a searchable, video-based knowledge library for the entire team. |

| Data Integration | Displays real-time IoT data on components. | Enables technicians to make faster, more informed decisions on-site. |

These capabilities transform AR from a futuristic concept into a practical, indispensable tool for modern industrial maintenance, providing teams with the information and support they need, when and where they need it.

How Industries Win with AR Maintenance

The true value of augmented reality maintenance becomes evident when it is applied to solve real-world problems. The technology has moved beyond pilot programs; across various industries, companies are integrating AR into their workflows and achieving tangible, bottom-line results. These are not minor adjustments but fundamental shifts in how work is performed.

Consider an aerospace engineer inspecting the highly complex wiring inside a jet engine. Instead of managing a tablet or referencing a laptop, they wear smart glasses. The correct wiring diagrams are overlaid directly onto the engine in their line of sight. The process is hands-free, faster, and dramatically reduces the risk of human error in a zero-tolerance environment.

This type of powerful, practical application is driving AR adoption. The global market's explosive growth is a testament to this, with projections showing it could reach USD 198.17 billion in the near future. Manufacturing and service industries are leading this expansion, accounting for over 23% of that revenue—a clear indication that maintenance is a key application.

Real-World Scenarios and Measurable Outcomes

On the factory floor, an unexpected shutdown of a critical production line is a plant manager's primary concern. With AR-enabled devices, technicians can approach a machine and instantly see a live feed of performance data from its IoT sensors overlaid on the physical equipment.

They can spot a minor temperature increase or a subtle vibration that signals an impending part failure. This foresight allows them to schedule maintenance before a breakdown occurs, transforming a potential crisis into a planned repair. This is especially true for manufacturers, who are using data from AR systems to power advanced analytics for manufacturers and turn operational data into profit.

The core benefit is transforming maintenance from a reactive, break-fix model into a proactive, predictive strategy. AR empowers teams to act on data, not just intuition, preventing downtime before it ever occurs.

The results are compelling. Companies that have implemented these solutions are seeing clear returns:

- Reduced Downtime: One chemical company reduced machine downtime from days to just a few hours by using AR to connect on-site technicians with remote experts between plants.

- Faster Service: An equipment manufacturer saved an average of two hours on every service case after implementing AR for training and live guidance.

- Lower Costs: By troubleshooting issues on ships remotely with AR, a marine equipment company cut its technician travel costs by 80%.

Field Service Transformed

Now, consider a field service agent dispatched to a hospital to repair a highly specialized piece of medical equipment. Previously, if they encountered a problem, it would mean scheduling a second visit with a senior specialist, leaving critical equipment offline and delaying patient care.

With augmented reality maintenance, that same agent can stream their point-of-view directly to a remote expert. The expert sees exactly what the agent sees and can guide them through the repair with visual instructions and annotations drawn onto their screen. The problem is solved on the first visit, improving customer satisfaction and making every field agent more capable and efficient.

Your Roadmap to Implementing AR Maintenance

Transitioning to augmented reality maintenance requires a strategic plan. The most successful implementations follow a phased approach, starting with a pilot program to prove the concept before scaling it across the entire operation.

The first step is to establish specific, measurable goals. What problem are you trying to solve? Perhaps you want to reduce machine downtime by 20%, boost first-time fix rates, or accelerate the onboarding of new technicians. Clear objectives will guide every decision, from hardware selection to software integration.

Building Your Foundation

With your goals defined, focus on the core elements of your AR system. This begins with selecting the right hardware for your specific work environment. Technicians needing their hands free for complex repairs will benefit most from smart glasses, while tasks allowing for more mobility might be better suited for ruggedized tablets.

Next is software integration. For an AR platform to deliver maximum value, it must integrate seamlessly with your existing enterprise systems, such as a Computerized Maintenance Management System (CMMS) or Enterprise Resource Planning (ERP) software. This connection ensures that work orders, asset data, and repair histories flow smoothly between systems, creating a single source of truth for your maintenance teams. To see how this technology works in a real-world setting, review our guide on augmented reality for maintenance.

Driving User Adoption and Success

Even the most advanced technology is ineffective if the team does not use it. User adoption depends on two factors: intuitive content and thorough training. The digital work instructions you create must be clear, visual, and easy for technicians to follow in real time.

The goal is to make the technology feel like a natural extension of a technician's skills, not another hurdle. A thoughtful training program that demonstrates practical, day-to-day benefits is essential for gaining team buy-in and ensuring long-term success.

Finally, address practical challenges like data security and on-site connectivity from the outset. As you map out your AR implementation, it is wise to adopt robust IT procurement best practices. This ensures your hardware and software acquisitions are secure, scalable, and aligned with your long-term goals. A proactive approach to these common hurdles will facilitate a smooth, successful AR maintenance program.

The Future of Augmented Reality in Maintenance

Augmented reality in maintenance is more than a tool; it is a cornerstone for the next generation of smart industrial operations. As it integrates with other transformative technologies, its role will evolve from simple assistance to become the predictive, intelligent core of the factory floor.

The true potential is unlocked when augmented reality is combined with Artificial Intelligence (AI) and the Internet of Things (IoT). Imagine a technician looking at a piece of equipment and seeing a predictive maintenance alert appear in their line of sight, triggered by an AI algorithm analyzing real-time data from IoT sensors. This shifts the system from being a helper to a proactive solution that prevents failures before they occur.

The Rise of the Industrial Metaverse

Another significant development on the horizon is the industrial metaverse, which involves creating hyper-realistic, persistent digital spaces for training and collaboration.

- Hyper-Realistic Simulations: A new technician can practice a complex repair on a perfect digital copy of a machine, allowing them to make mistakes, learn the process, and build confidence in a safe, consequence-free environment.

- Collaborative Design and Planning: Engineers from different locations can meet inside a virtual factory to walk the floor, plan new maintenance schedules, or troubleshoot a new equipment layout without leaving their offices.

This transforms AR from an information overlay into an immersive, collaborative platform, enabling the development of a more skilled, prepared, and connected industrial workforce.

Unprecedented Diagnostic Power

The final component is pairing AR with digital twins—exact virtual replicas of physical assets. A technician can use an AR headset to overlay a machine's digital twin directly onto the real asset. This allows them to "see" inside the machine, watch it operate virtually, and diagnose problems with an unprecedented level of accuracy.

The market growth reflects this potential. The global augmented reality market is expected to expand from approximately USD 149.57 billion to nearly USD 2,804.82 billion in the next decade. This growth is driven by the very innovations creating the resilient, efficient, and intelligent factories of tomorrow. You can explore more AR market growth insights at Precedence Research.

Got Questions About AR Maintenance? Let's Answer Them.

Adopting any new technology is a significant step, and it is natural to have questions before committing. Leaders need to understand the practical aspects first. Here are straightforward answers to common questions about costs, hardware, and integration challenges.

What’s a Realistic ROI for an AR Maintenance Project?

While results vary depending on the specific application, most companies see a return on their investment within 12 to 24 months. The value is derived from measurable improvements, such as reduced machine downtime, lower travel costs for expert support, and a significant decrease in preventable errors.

The largest financial benefit often comes from the increase in first-time fix rates.

The most effective way to determine your ROI is to run a pilot project. This allows you to benchmark your current operations, calculate a precise return, and build a strong business case before a full-scale implementation.

What Kind of Hardware Do We Actually Need?

There is no single answer; the right equipment depends on the job. You must match the device to your work environment and the complexity of your technicians' tasks.

- AR Smart Glasses: For jobs where technicians need their hands free, devices like the Microsoft HoloLens or the RealWear Navigator are ideal. They place critical information directly in the user’s line of sight without obstructing their work.

- Tablets and Smartphones: For mobile technicians or simpler tasks, a rugged tablet or smartphone is effective. They are excellent for displaying 3D models or walking through digital work instructions.

How Does AR Fit in with the Software We Already Use?

Modern AR maintenance platforms are designed for interoperability. They use APIs (Application Programming Interfaces) to connect directly with existing enterprise systems, whether it’s a CMMS, EAM, or ERP.

This connection ensures that information flows seamlessly in both directions. For example, a new work order logged in your CMMS can automatically trigger an AR-guided workflow for a technician. Upon completion, the AR system sends an update back to the CMMS, maintaining data integrity and improving efficiency.

Ready to see how AR can completely change your maintenance and training game? The team at AIDAR Solutions specializes in this field. We build immersive AR and VR applications that deliver real results, from cutting service times in half to quadrupling training throughput. Discover our tailored solutions and start building a more efficient, resilient workforce today.