Augmented Reality in Manufacturing: A Practical Guide

Augmented reality in manufacturing acts as a digital co-pilot for frontline workers. It overlays critical information—such as interactive instructions, 3D models, or live performance data—directly onto their view of the factory floor.

This creates a powerful, real-time guide that transforms even the most complex jobs into simple, step-by-step processes. It functions as a GPS for industrial operations, showing personnel exactly where to go and what to do next.

What Is Augmented Reality in Manufacturing?

Imagine a technician preparing to repair a complex piece of machinery. Instead of consulting a paper manual or juggling a tablet, they put on a pair of smart glasses.

Through the lenses, they see the actual machine, but it is enhanced with digital information. Arrows point to the exact bolts that need loosening. Text labels pop up to identify specific parts. Animated instructions play out in their field of view, showing the correct sequence of actions.

This is the practical application of augmented reality in manufacturing. It is not about replacing human skill; it is about amplifying it. By blending digital information with the physical world, AR delivers immediate, context-aware guidance right when and where it's needed most. This reduces cognitive load and eliminates guesswork.

The Core Function of AR on the Factory Floor

At its heart, AR provides an intuitive way to deliver information to personnel. It fundamentally changes how workers interact with their environment by providing crucial data without requiring them to look away from their work.

To fully appreciate the significance of this, it is helpful to understand the daily pressures and dynamics of the manufacturing sector itself. The primary goal is always to make operations safer, faster, and more accurate—and that is precisely what AR helps achieve.

Here are a few of the key functions AR performs on the factory floor:

- Guided Workflows: Projects step-by-step instructions for assembly, maintenance, or repairs directly onto the equipment.

- Real-Time Data Visualization: Displays live data from sensors—such as temperature, pressure, or speed—as a digital overlay.

- Remote Expert Assistance: Allows an off-site expert to see what a technician sees and provide real-time audio and visual guidance, annotating directly into their view.

- Digital Quality Checks: Overlays a correct 3D model of a finished part onto the physical product to instantly flag any defects or deviations.

Augmented reality bridges the gap between the digital blueprint and the physical product. It gives workers a direct line of sight into the information they need to perform their jobs with greater precision and confidence.

A Growing Industrial Standard

This technology is no longer a futuristic concept; it is quickly becoming a standard operational tool. The market growth illustrates this trend.

Projected AR hardware revenue is expected to increase from $1.85 billion in 2021 to over $35 billion by 2026. This explosive growth shows how seriously industries are taking AR, integrating it into their most critical tasks to boost efficiency and empower their people with instant access to information.

How AR Transforms Core Manufacturing Operations

Augmented reality ceases to be a buzzword and becomes a practical tool the moment it is brought to the factory floor. By layering digital information over the physical world, AR addresses some of the most persistent challenges in manufacturing: human error, production delays, and knowledge gaps. It creates a guided, more accurate, and more efficient production environment.

The technology fundamentally changes how people interact with complex machinery. Instead of glancing back and forth between a manual or a screen, your team receives instructions directly in their line of sight. This allows them to work faster and with more confidence.

Streamlining Complex Assembly

One of the first areas to see a massive impact is on the assembly line. Traditionally, a worker juggles printed schematics or static work instructions, constantly breaking focus to check the next step. This cognitive load slows down processes and is a classic recipe for mistakes.

AR eliminates that friction. An assembler using smart glasses or a tablet sees a 3D, step-by-step guide projected directly onto their workstation.

- Digital Overlays: Animated graphics show exactly where a part goes or which bolt to tighten, eliminating guesswork.

- Tool Guidance: The system can highlight the correct tool for each step, ensuring the right equipment is used every time.

- Sequence Validation: AR can even confirm a step is completed correctly before allowing the worker to proceed, building quality control directly into the assembly process.

This visual guidance transforms a complex job into a simple follow-along task, a key benefit found in resources on augmented reality in manufacturing. The payoff is a significant reduction in assembly errors and a substantial increase in production speed.

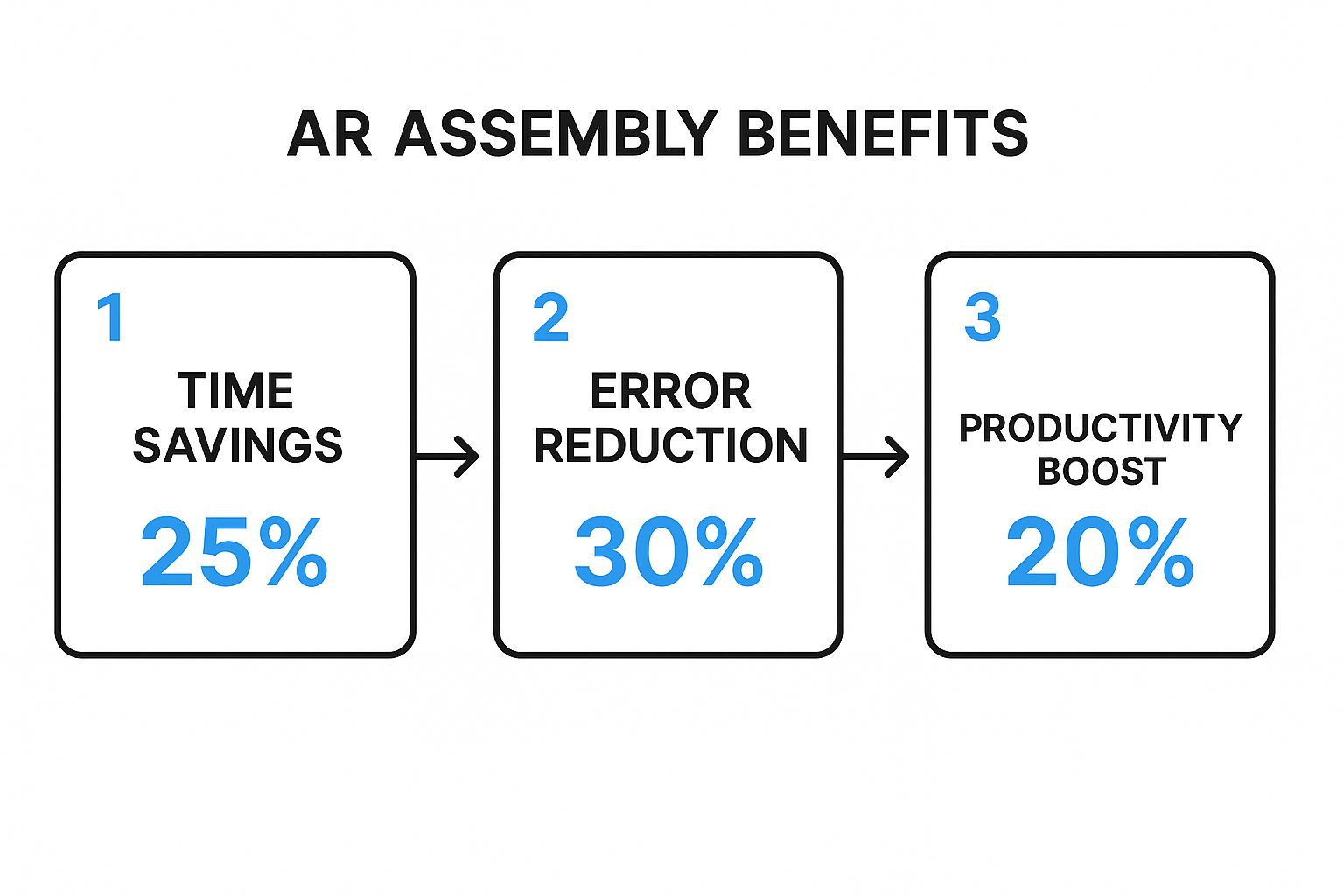

The image below illustrates how AR's benefits compound, from time savings to higher factory output.

It is a clear chain reaction: saving time upfront leads directly to fewer errors, which ultimately drives a major increase in overall productivity.

To put this into perspective, let's compare the traditional method with the new. The table below shows the significant changes when AR is introduced.

Comparing Traditional and AR-Enhanced Workflows

| Manufacturing Process | Traditional Method | AR-Enhanced Method | Key Improvement |

|---|---|---|---|

| Assembly | Printed manuals or static screen instructions. | Step-by-step 3D overlays projected onto the workspace. | Reduced errors and faster assembly times. |

| Quality Control | Manual visual inspection against a checklist or spec sheet. | Real-time overlay of a perfect CAD model on the physical part. | Faster, more accurate defect detection. |

| Maintenance & Repair | Waiting for an expert to travel to the site for complex issues. | On-site technician streams POV to a remote expert for live guidance. | Dramatically lower machine downtime. |

| Training | Classroom sessions and shadowing experienced workers. | Hands-on, guided training on actual equipment with simulated tasks. | Faster onboarding and improved knowledge retention. |

As you can see, AR is not just a minor tweak—it is a fundamental upgrade to how work gets done, making processes more intuitive and less prone to error.

Improving Quality Assurance Accuracy

Quality assurance is another area that receives a major upgrade. Manual inspections are often slow and prone to human error. It is easy to miss a tiny deviation from the design specification, especially after inspecting hundreds of parts.

AR provides inspectors with a tool to spot issues with incredible speed and precision. An AR application can overlay a correct CAD model directly onto a finished product. Instantly, any misalignment, missing component, or surface flaw is highlighted for the inspector. This approach strengthens many modern strategies for quality assurance in manufacturing by making defect detection less subjective and significantly faster.

By comparing the physical product against its digital twin in real time, AR empowers inspectors to catch defects that the human eye might miss, ensuring higher quality standards and reducing rework costs.

This is a game-changer for parts with complex geometries or extremely tight tolerances, where even a microscopic error can cause a major failure down the line.

Enabling Real-Time Remote Assistance

Equipment downtime is a manufacturer's greatest operational risk. When a key machine goes down, the entire line can grind to a halt. The clock is ticking—and revenue is being lost—until a specialist can get on-site to diagnose the problem. This can take hours, or even days.

AR-powered remote assistance eliminates these geographic barriers. An on-site technician wearing smart glasses can stream their exact point-of-view to an expert located anywhere in the world.

The remote expert sees what the technician sees and can offer immediate, hands-on assistance. They can:

- Annotate the live video feed, drawing circles or arrows that "stick" to the physical machine to point out specific areas.

- Push technical documents or schematics directly into the technician's display.

- Walk them through the repair step-by-step, ensuring every action is performed correctly.

This "see-what-I-see" capability dramatically reduces the mean time to repair (MTTR). Problems that used to require expensive travel and lengthy delays can now be resolved in a fraction of the time, keeping the production line running.

The Measurable Business Impact of AR

While the technology itself is impressive, the real story of augmented reality in manufacturing is told through key performance indicators. This is not just about making the factory floor look futuristic; it is a strategic investment that delivers a clear, measurable return by improving critical KPIs.

Beyond the initial excitement, the hard data provides the information decision-makers need. AR translates directly into fewer mistakes, faster operations, and a more capable workforce. This is how you build a solid business case for integrating AR into your operations.

Slashing Errors and Boosting First-Time Quality

One of the most immediate impacts of AR is a dramatic reduction in human error. On a complex assembly line, even a small mistake can snowball into expensive rework, wasted materials, and significant delays. AR acts as a real-time guide, assisting workers and ensuring precision.

By overlaying digital templates and step-by-step instructions directly onto a physical component, it becomes much more difficult to place the wrong part in the wrong place. In fact, some companies have seen a 90% reduction in errors on complex tasks after implementing AR-guided workflows.

AR fundamentally changes quality control. Instead of catching mistakes at the end of the line, you prevent them from happening in the first place. This "first-time-right" approach is the bedrock of modern, efficient manufacturing.

This has a massive impact on first-time quality (FTQ) rates, a metric that directly affects profitability. Better FTQ means less capital wasted on fixes and more time spent on production. Improving these core metrics is fundamental to any effort to improve manufacturing productivity, and AR provides a direct path to achieving that.

Accelerating Maintenance and Repair Cycles

Downtime is a critical challenge. Every minute a key machine is offline, you are losing money. AR reduces the Mean Time to Repair (MTTR) by providing technicians with the exact information they need, right when and where they need it.

Instead of searching through a large manual or a tablet, a technician wearing AR glasses sees schematics and sensor data layered directly onto the machine they are repairing. Furthermore, they can use a "see-what-I-see" video link to bring in a remote expert who can guide them through the repair as if they were standing right there.

The results are immediate and tangible:

- Faster Diagnostics: Technicians pinpoint the root cause in a fraction of the time with live data and visual aids.

- Reduced Repair Time: Step-by-step visual guidance removes guesswork, cutting service times by as much as 50%.

- Lower Travel Costs: Remote assistance has helped some businesses reduce expert travel expenses by 75%.

Revolutionizing Workforce Training and Upskilling

The benefits of AR extend beyond daily production numbers; they reach the core of how you build your team. Traditional training methods like classroom sessions and shadowing are often slow and can lead to inconsistent results.

AR creates an immersive, hands-on learning environment. New hires can train on real equipment without any risk of causing damage or slowing down a live production line. Digital instructions guide them through the process, helping them build muscle memory and confidence from day one. Studies have shown AR-based training can reduce training time by up to 75% and improve information retention.

This is not just about onboarding new people faster. It is also a powerful way to upskill your existing team on the fly. When a new machine or process is introduced, AR delivers "just-in-time" training right on the factory floor. Your crew stays sharp and agile without having to stop production for a formal training day.

Building Your AR Implementation Roadmap

Implementing augmented reality in manufacturing requires a clear, methodical plan that solves genuine problems and demonstrates value quickly. A solid roadmap is what transforms an interesting technology into a powerful operational advantage.

The best approach is to start small. Instead of a massive, factory-wide rollout, launch a focused pilot project. This allows you to test the technology, learn what works, and build a solid business case in a controlled setting before committing to a larger-scale deployment.

Choosing Your First Pilot Project

Your first AR project should target a specific, high-impact pain point. Look for operations that are known for errors, slow cycle times, or require extensive training. The ideal pilot candidate has a clear problem to solve and metrics you can measure.

Consider where AR’s unique strengths can provide the most benefit on the factory floor:

- Complex Assembly: Identify a process plagued by a high error rate. This is where step-by-step visual guidance can make an immediate, game-changing difference.

- Maintenance Procedures: Target a piece of equipment that suffers from frequent downtime or requires a highly specialized technician for repairs.

- Quality Inspections: Select a component where manual checks are slow and subjective. Digital overlays can bring a new level of accuracy and consistency.

The primary goal of a pilot is not just to test the technology. It's to prove a clear return on investment. Choose a challenge where success will be obvious and meaningful to your bottom line.

Once you have selected your project, define what success looks like. You need to establish baseline metrics before you begin. If you're addressing assembly, track your current error rate, average time per unit, and new hire training time. These numbers will be your proof of concept.

Evaluating Hardware and Software Solutions

The AR market offers a wide range of options—from smart glasses and headsets to rugged tablets and smartphones. The right choice depends entirely on the task and the environment. A maintenance technician who needs their hands free will benefit from smart glasses. A quality inspector at a fixed station may be more efficient with a tablet.

Do not overlook ergonomics and comfort, which are critical for adoption. Involve your frontline workers in the selection process. Let them try different devices to see what feels natural and does not interfere with their work. A device that is clunky or uncomfortable will go unused, regardless of its features.

Looking forward, the industry is moving toward greater hardware flexibility, allowing a switch between devices like smart glasses and projection systems. This adaptability not only makes AR more cost-effective and scalable but also caters to different worker preferences. You can explore these 2025 trends for augmented reality in manufacturing to see what's next.

Integrating and Scaling Your AR Program

To truly unlock its power, AR cannot exist in a silo. It must communicate with your other systems. Seamless integration with your Manufacturing Execution System (MES) and Product Lifecycle Management (PLM) software is essential. This connection allows AR tools to pull the latest work instructions, 3D models, and real-time data automatically, ensuring your team always has the correct information.

Data security is another critical component. When overlaying digital information onto your physical operations, you must protect your sensitive IP and operational data. Involve your IT department early to establish robust security protocols for the devices and the data they access.

Once your pilot project has proven successful, it is time to plan the scale-up. Use the lessons learned to refine your approach, then begin replicating your success in other areas facing similar challenges. A well-executed roadmap transforms that first small win into the foundation for a full-scale operational upgrade.

The Tech Making AR on the Factory Floor Possible

The recent growth of augmented reality in manufacturing is not an overnight phenomenon. It is the result of years of software and hardware development finally aligning with industrial needs. This progress has transformed AR from an interesting concept into a practical tool for the factory floor.

At its core is a powerful combination of smart software and capable hardware. Early AR equipment was bulky, expensive, and had limited functionality. Today's technology is a different story, featuring sleek, lightweight smart glasses and the powerful mobile devices we all use, making it easier than ever for manufacturers to get started.

AI and Computer Vision: The Brains of the Operation

Modern AR derives its intelligence from artificial intelligence (AI), particularly a field called computer vision. You can think of computer vision as the "eyes" of the system. It gives the software the ability to recognize and understand real-world objects, from a small machine part to an entire assembly line.

This is what makes AR genuinely interactive and context-aware. An AR application with robust computer vision can:

- Identify Equipment: Instantly recognize a machine and overlay its maintenance history or live performance data.

- Track Components: Follow a technician's hands and the parts they are working with to ensure they follow the correct assembly steps.

- Spot Defects: Compare a finished product against its digital blueprint to automatically flag any deviations.

AI gives AR the ability not just to display information, but to understand what it is seeing and provide the right guidance at the right time. This is the core technology behind many of the augmented reality industrial applications that are making a real difference in operations.

AR Hardware That People Actually Want to Wear

Of course, software is only half the battle. The physical hardware has improved significantly. The evolution from heavy, cumbersome headsets tethered by wires to the ergonomic devices available today has been crucial for user adoption. A tool is useless if it is too uncomfortable or awkward to wear for a full shift.

It is this parallel progress in both AI and specialized hardware that is driving AR forward in manufacturing. By 2025, AI skills like computer vision, object tracking, and spatial mapping are making AR applications incredibly precise and context-aware. At the same time, hardware breakthroughs like highly efficient MicroLED displays and dedicated AR chips from leading technology companies are making devices more powerful and comfortable, creating a healthy, competitive market that benefits users.

The ideal AR device for a factory worker should feel like a natural extension of themselves—unobtrusive, intuitive, and durable enough for the environment. Comfort and ease of use are just as critical as raw processing power.

This focus on the user ensures that AR technology assists workers instead of hindering them, making all-day use a real possibility. AR is not the only technology changing the factory floor; it is also being reshaped by innovations like advancements in additive manufacturing, which opens up entirely new ways to design and build.

What's Next for AR in Smart Factories?

The augmented reality applications we are seeing in manufacturing today are just the beginning. Looking ahead, AR is poised to become less of a standalone gadget and more of an intelligent, essential partner for the industrial workforce. The next wave will be defined by deep system integration, proactive guidance, and seamless collaboration.

As AR integrates with other key technologies, it is paving the way for a factory floor that is more connected and predictive than ever before. We are moving beyond simple instruction overlays to create a living, responsive operational ecosystem.

Deeper Connections with Digital Twins

One of the biggest future developments is linking AR directly to Digital Twins. A Digital Twin is a perfect virtual replica of a physical asset—a single machine, or even an entire production line—that is constantly updated with real-time data from sensors. By connecting AR to these live digital models, we create a powerful bond between the physical and virtual worlds.

Imagine a maintenance technician pointing their AR headset at a complex piece of machinery. They would see more than just a static repair manual; they would see a live, interactive X-ray of the machine's inner workings.

- Predictive Maintenance Alerts: The AR display could highlight a component that the Digital Twin predicts is about to fail, enabling a proactive repair before a catastrophic breakdown halts production.

- Advanced Simulations: Before physically altering a machine, engineers could use AR to simulate a proposed change on the virtual model, seeing the impact instantly. This de-risks modifications and helps optimize equipment performance.

This seamless link transforms AR into a window, showing not just what is happening now, but what is likely to happen next.

The Rise of Context-Aware AR

Future AR systems will feel less like a tool you command and more like an intelligent assistant that anticipates your needs. By using AI to analyze a worker’s actions, their location, and the task at hand, these systems will offer "just-in-time" guidance, often before the user even asks for it.

Instead of just reacting to voice commands, the next generation of AR will act like a perceptive partner, offering unsolicited advice and flagging potential issues in real time.

For example, an AR system might notice an assembly worker reaching for the wrong size bolt and immediately flash a visual warning. Or it could automatically display the relevant safety protocol the moment a technician enters a high-voltage zone. This shift from reactive to proactive assistance is a game-changer for making operations safer and more efficient.

Collaborative AR for Supercharged Teamwork

Finally, the future is about collaborative AR. This allows multiple people to see and interact with the same digital information in a shared physical space, completely changing how teams solve complex problems.

Engineers, technicians, and designers—even if they are in different locations—can gather around and manipulate the same 3D model of a new product prototype. This shared digital workspace removes communication barriers and makes design reviews, troubleshooting sessions, and group training feel as if everyone is in the same room. This level of connection will be a defining feature of the smart factory of tomorrow.

Answering the Tough Questions About AR in Manufacturing

Any time you introduce a new technology to the factory floor, questions arise. It is only natural. Decision-makers need to understand the practical implications before making a significant investment. Getting clear, direct answers is what moves the conversation from "what if?" to "how do we begin?"

Let's address some of the most common questions to provide a full picture—the challenges, the potential, and the real-world impact.

What Are the Biggest Implementation Hurdles?

While the benefits are significant, deploying AR in a live factory setting has its challenges. The biggest hurdles often involve people and existing processes, not just the technology itself.

- System Integration: An AR platform that cannot communicate with your existing systems, like an MES or PLM, has limited value. The real power comes when it can pull live data from your core operations. Seamless integration is essential.

- User Adoption and Training: A tool is only as good as the people who use it. Gaining buy-in from your frontline crew means the hardware must be comfortable, the software intuitive, and the training effective. It is critical to frame AR as a tool that makes their jobs easier, not another complex system to learn.

- Content Creation: Building the initial library of AR work instructions and 3D models can seem daunting. The key is to choose a platform that simplifies this process—ideally one that can streamline or automate content creation directly from your existing CAD files.

How Do You Actually Calculate the ROI?

Calculating the return on investment for an AR project goes beyond the cost of headsets and software. The real value is measured by its impact on the KPIs you are already tracking.

First, you need a baseline. Know your numbers before you start. Then, once your pilot project is running, measure those same metrics again to see what has changed.

The formula for AR ROI is relatively simple. It’s the total cost savings from fewer errors, the productivity gains from faster work, and the money saved from less downtime and travel—all weighed against the investment in the solution.

This data-driven proof not only justifies the pilot but also builds a compelling business case for rolling out the technology across your entire operation.

Is AR Going to Replace Our Skilled Workers?

This is perhaps the most important question, and the answer is a firm no. AR is not about replacing skilled people; it is about making them even better at what they do. It is a digital tool that amplifies their expertise.

Think of it as a force multiplier for the talent you already have. By providing real-time information and visual guidance, AR reduces the cognitive load on your veterans, freeing them to focus on complex problem-solving. At the same time, it radically shortens the learning curve for new hires. Our guide on using augmented reality for training dives deeper into how this technology builds a more capable and confident team.

At AIDAR Solutions, we specialize in using AR and VR to solve real-world industrial problems. If you're ready to see how immersive technology can reduce errors, slash downtime, and build a more powerful workforce, explore our solutions at https://aidarsolutions.com.