Augmented Reality for Maintenance: A Practical Guide

Traditional maintenance methods are often inefficient. Technicians frequently search through bulky manuals, rely on the institutional knowledge of veteran employees, or make multiple calls to off-site experts. This approach leads to costly downtime, human error, and a significant skills gap that widens with every experienced technician's retirement.

For years, these were accepted costs of doing business. Now, a more effective approach is available. Augmented reality (AR) is transforming the industry by fundamentally changing how technicians see, understand, and interact with the equipment they service.

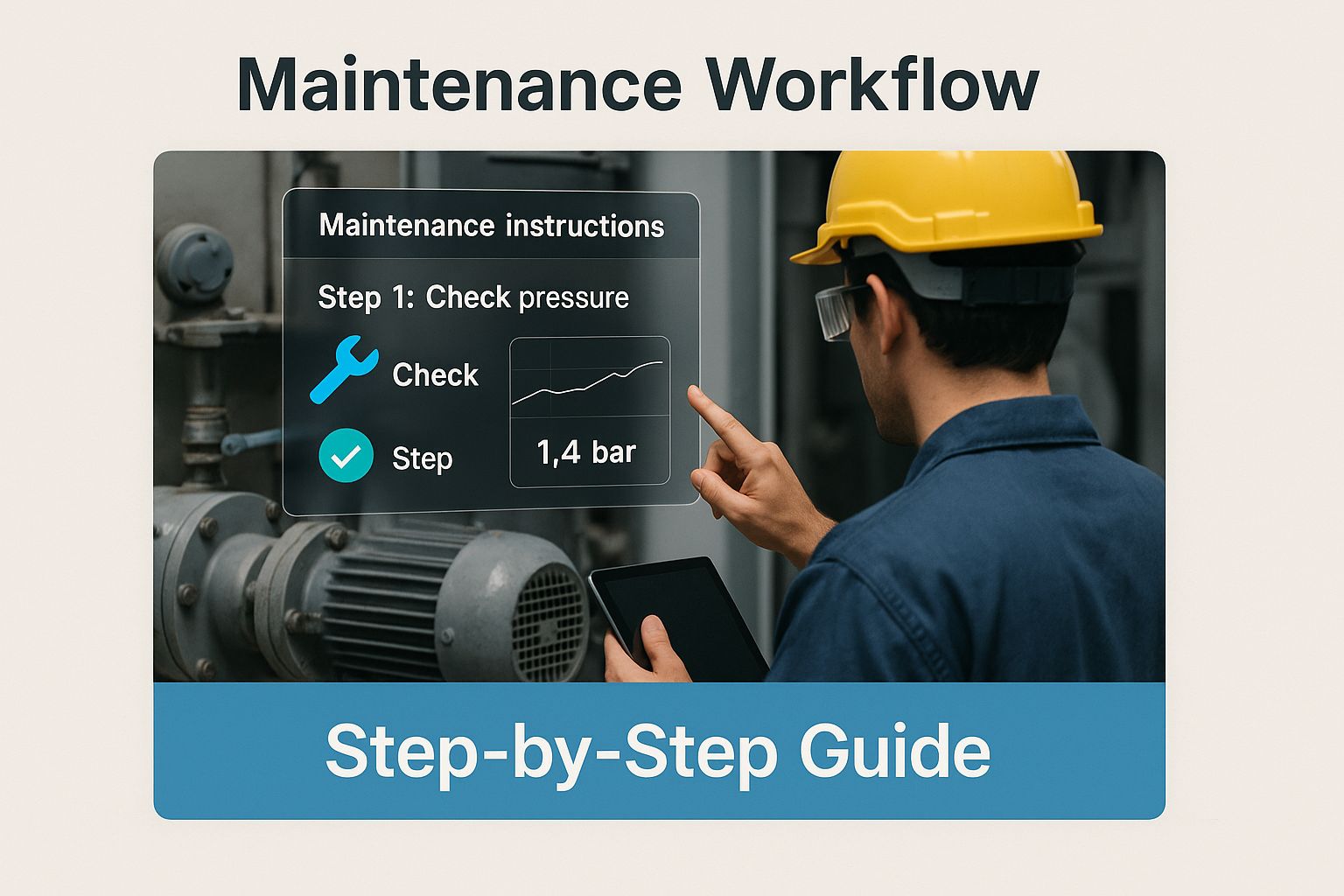

Imagine a technician looking at a machine through a tablet or smart glasses. Instead of searching for a schematic, they instantly see live operational data, safety warnings, or animated instructions showing them precisely which component to adjust. That is the practical power of AR.

A New Reality for Industrial Maintenance

At its core, augmented reality for maintenance bridges the gap between a physical piece of equipment and its corresponding digital information—manuals, sensor data, and repair histories. This connection provides frontline workers with the exact knowledge they need, at the moment they need it, solving some of the industry's most persistent challenges.

Bridging the Physical and Digital Worlds

This technology provides teams with industrial-grade insight. This new capability directly tackles the biggest pain points in the field:

- Slash Downtime: When repair guides and expert assistance are available instantly, troubleshooting that previously took hours can be completed in minutes.

- Boost Accuracy: Clear, visual, step-by-step instructions eliminate guesswork from complex repairs. This results in higher first-time fix rates and fewer mistakes.

- Improve Safety: Using smart glasses, technicians can keep their hands on their tools and their eyes on the job, all while viewing critical data and safety alerts in their line of sight.

- Close the Skills Gap: A senior expert can be anywhere in the world and still guide a junior technician on-site through a repair in real-time. It's effective, on-the-job training.

By layering digital intelligence over the physical workspace, AR does more than simplify maintenance—it makes the entire operation smarter. It turns every technician, from novice to seasoned professional, into a more capable and efficient problem-solver. This is a practical tool solving real-world industrial problems today.

How Augmented Reality Actually Works in a Maintenance Setting

Augmented reality in a maintenance workflow functions like a high-tech GPS for repairing complex machinery. Instead of guiding you through city streets, it guides a technician step-by-step through a repair. AR overlays digital instructions, diagrams, and crucial data directly onto their real-world view of the equipment. This blend of the digital and physical worlds removes guesswork from complex jobs, arming technicians with the exact information they need, right when they need it.

An AR maintenance solution is an ecosystem of different components working in harmony. These pieces come together to translate raw data into clear, actionable steps for the person on the ground, making even the most complicated tasks feel intuitive.

The Core Components of an AR Solution

The true value of augmented reality for maintenance is realized when hardware, software, and your existing company data integrate seamlessly. Each piece of this puzzle has a critical role.

-

AR Hardware: This is the device a technician uses to see the augmented world. It could be a familiar tool like a tablet or smartphone, or specialized, rugged smart glasses built for demanding industrial environments. The right choice depends on the job. For hands-free work, smart glasses are the logical choice. For reviewing detailed schematics, a tablet's larger screen is often preferable.

-

Software Platforms: The software is the brain of the operation. It processes data, creates digital overlays, and runs the user interface. These platforms are used to build AR-guided work instructions, initiate remote support calls with experts, and develop training modules for new hires.

-

System Integration: This is where the full power is unlocked. AR tools become exponentially more valuable when connected to a company's existing systems, like a Computerized Maintenance Management System (CMMS) or an Enterprise Resource Planning (ERP) platform. This connection allows a technician's AR headset to automatically pull up the correct work order, review an asset's repair history, and see live performance data—all without returning to a computer.

Turning Complex Data Into Something You Can Use

Beyond showing step-by-step instructions, AR acts as a bridge to other powerful industrial concepts like the Industrial Internet of Things (IoT) and digital twins. These technologies produce a large volume of data, which can be overwhelming without an effective way to visualize it.

A digital twin, for instance, is a complete virtual model of a physical piece of equipment. With AR, a technician can look at a real-world motor and instantly see its digital twin overlaid on top, showing live data from IoT sensors like its current temperature, vibration levels, and expected output.

This transforms abstract data points into a practical tool. Instead of digging through a report, a technician can literally see a component glowing red on their screen, instantly flagging an overheating problem that needs immediate attention.

This capability is becoming increasingly common. The global AR market is growing rapidly and significantly impacting maintenance. The number of active mobile AR users is expected to surpass 2 billion people, with 75% of the global population projected to be active AR users by 2025. For industries, this presents a massive opportunity to use the technology for immersive training simulations and on-the-spot expert support, which directly reduces errors and costly downtime.

This on-demand access to information is especially powerful for closing the skills gap. By providing rich, visual context, you can see how augmented reality for training helps a new technician tackle a complex job with the confidence of a seasoned pro, bridging years of experience, one guided repair at a time.

Core Business Benefits of AR Maintenance Solutions

Integrating augmented reality into your maintenance workflow is more than a technology upgrade. It’s a fundamental shift in how work is performed, delivering measurable value by tackling some of the most stubborn and expensive challenges in the industrial sector.

When you layer digital information directly onto a technician's view of the real world, you empower them to solve problems faster, more accurately, and with greater confidence, regardless of their experience level. The impact is reflected in the bottom line.

This is not theoretical. It results in a more resilient, efficient, and capable maintenance team from day one.

This image captures the essence of AR: step-by-step guidance appears exactly where the work is happening. That simple visual overlay is the key to unlocking major improvements in both speed and accuracy.

Slashing Repair Times and Boosting Uptime

Let's discuss Mean Time to Repair (MTTR). In any industrial setting, this metric is a key concern for managers. Traditional methods—searching through manuals or locating a senior technician for advice—consume hours and reduce productivity. AR eliminates these delays.

Imagine a technician wearing AR glasses or holding a tablet. They look at a machine, and interactive work instructions are instantly overlaid onto the equipment. There is no guesswork and no flipping through pages. They see the problem, follow the digital steps, and complete the fix.

This is not just about faster repairs; it's about getting equipment back online sooner. When a critical asset is operational hours or even days earlier than it would have been, the value of that reclaimed production time is enormous.

And if they encounter an issue? Remote assistance lets an on-site technician share their view with an expert anywhere in the world. That expert can see what they see, draw annotations in their field of vision, and walk them through the solution live. This feature alone eliminates costly travel and turns a potential crisis into a quick, collaborative fix.

Improving First-Time Fix Rates

Getting the job done right the first time is a massive driver of efficiency. First-Time Fix Rate (FTFR) is a direct reflection of maintenance quality, and AR is one of the most powerful tools for improving it.

By showing technicians exactly what to do and in what order, AR minimizes the human error that leads to rework. Imagine seeing an animated overlay showing the precise disassembly sequence or the exact torque setting for a bolt displayed on your screen. The probability of a mistake drops dramatically.

This focus on accuracy has positive effects throughout the operation:

- Less Waste: Fewer incorrect repairs mean you're not using spare parts unnecessarily.

- Better Reliability: When maintenance is performed correctly every time, equipment runs better for longer.

- More Confident Techs: Newer technicians can tackle complex jobs with the confidence of a seasoned veteran.

Enhancing Workplace Safety and Training

Safety is non-negotiable. With augmented reality for maintenance, you're building a safer environment by design. Smart glasses enable hands-free work, meaning technicians can keep their eyes on the task and their hands on their tools, not fumbling with a tablet or manual.

AR can also act as a digital safety system, overlaying warnings on high-voltage areas or dangerously hot surfaces. This real-time situational awareness is invaluable for preventing accidents.

Beyond the immediate safety benefits, AR is an excellent training tool. A new hire can learn a complex procedure on actual equipment with digital guidance, freeing up senior technicians to focus on their own critical tasks. It’s effective, on-the-job training that brings new team members up to speed faster and at a lower cost.

Data supports these claims. Over 60% of companies link AR-powered maintenance to better productivity, less downtime, and improved safety. And when you consider that nearly 50% of maintenance costs are often attributed to inefficient practices, the business case becomes clear. Immersive tech is a powerful solution, which is why it's worth exploring how virtual reality can save businesses time and money in related areas like simulation-based training.

Impact of AR on Key Maintenance Metrics

To summarize, let’s look at a direct comparison of how AR transforms traditional maintenance challenges into tangible wins across key metrics.

| Maintenance Metric | Traditional Challenge | Improvement with AR |

|---|---|---|

| Mean Time to Repair (MTTR) | Technicians waste time searching for manuals or waiting for expert help, leading to extended downtime. | Instant access to digital work instructions and remote expert guidance dramatically reduces repair time. |

| First-Time Fix Rate (FTFR) | High rates of human error and inconsistent procedures lead to repeat work and wasted parts. | Step-by-step visual guidance ensures procedures are followed correctly, significantly increasing accuracy. |

| Workplace Safety | Juggling manuals and tools increases cognitive load and risk; hidden dangers are not always apparent. | Hands-free operation and digital hazard warnings create a safer, more focused work environment. |

| Technician Training | Training is time-consuming, expensive, and often requires pulling senior staff away from their duties. | On-the-job, guided learning accelerates skill acquisition and reduces the burden on experienced mentors. |

This table shows a clear pattern: AR directly addresses the friction points in conventional maintenance, replacing ambiguity and delay with clarity and speed.

Where the Rubber Meets the Road: AR in Action

This is where augmented reality transitions from a concept to a problem-solving tool for technicians in the field. The technology is a practical solution that delivers measurable results, whether on a factory floor, an offshore oil rig, or an aircraft hangar.

Across these different fields, AR tackles the same core challenges: complexity, distance, and the need to deliver knowledge where it's needed most. Let's look at a few scenarios that show how AR is already being used today, proving its worth in industries where uptime and precision are critical. You'll often find AR making its biggest splash in demanding manufacturing and industrial environments.

Remote Expert Assistance in the Energy Sector

Consider a junior technician on a remote wind turbine. A critical gearbox sensor fails. The nearest senior engineer is hundreds of miles away at the main office. Before AR, this situation meant significant downtime while waiting for the expert to travel, or a risky repair attempt guided by phone calls and low-resolution photos.

With AR, the scenario changes completely. The field technician puts on a pair of smart glasses and starts a video call with the senior engineer. Instantly, the expert sees exactly what the technician sees, live.

Through this shared view, the expert can guide the repair with total precision. They can circle the exact component on the technician’s screen, freeze the video to point out a tricky connection, and even pull up the correct schematic and display it right in the technician's line of sight.

The problem is fixed in a fraction of the time, providing huge benefits:

- Drastically Reduced Downtime: The turbine is operational again in hours, not days.

- Zero Travel Costs: The expert provides guidance from their desk, saving thousands on travel and logistics.

- On-the-Job Training: The junior technician gains valuable hands-on experience with an expert guiding their every move.

Interactive Work Instructions for Aerospace Maintenance

When working on a jet engine, there is no room for error. Maintenance involves thousands of steps, and a single misplaced bolt could have catastrophic results. Technicians have traditionally relied on large, cumbersome paper manuals.

Augmented reality replaces these manuals. Now, a technician can look at an engine component, and the AR software immediately recognizes it. Dynamic, 3D animations appear directly on top of the equipment, walking them through the entire procedure.

The system shows them which tool to use, highlights the exact bolts to loosen (and in what order!), and displays the required torque values. As each step is completed, it’s automatically checked off and logged, creating a flawless digital audit trail. This approach is a perfect example of how augmented reality changes the way we handle complex, procedural work.

The result? Maintenance is not just faster; it's dramatically more accurate and reliable. This leads to better safety, easier compliance with strict aviation regulations, and a more confident, capable workforce.

Digital Twin Visualization in Manufacturing

Imagine a large automotive plant where a key robotic arm on the assembly line begins to malfunction. A plant manager needs to identify the problem before it shuts down the entire line, but the sensor data is located in a complex dashboard.

Instead, the manager uses an AR-enabled tablet and walks over to the robot. They point the camera at it, and a digital twin—a virtual replica—is overlaid onto the real machine. This isn't just a static 3D model; it's a live feed of the robot's health.

They can see real-time data like motor temperature, joint stress, and cycle times displayed directly on the corresponding physical parts. The AR interface instantly flags an actuator that's vibrating outside its normal range, pinpointing the likely source of a future failure. The manager can then schedule predictive maintenance with precision, replacing only the at-risk component.

This use of augmented reality for maintenance turns reactive data into a proactive, decision-making tool. It gives leaders the ability to "see" inside their machines, make smarter decisions faster, and prevent expensive, unplanned downtime before it happens.

Choosing the Right AR Hardware and Software

Selecting the right tools is a critical first step when integrating augmented reality into your maintenance operations. This process is not about adopting the newest technology, but about carefully matching the solution to the daily tasks of your technicians. The right choice empowers your team, while the wrong one can lead to an expensive and underutilized tool.

It all starts with the hardware. The most common options each play a specific role in an augmented reality for maintenance strategy.

Selecting the Best Hardware for the Job

Your hardware choice will determine user adoption and the success of your entire AR program. Each device type has clear advantages and disadvantages depending on the maintenance work being performed.

-

Smart Glasses (Monocular and Binocular): These are the standard for hands-free work. Binocular glasses provide a more immersive, two-eyed view, while monocular (single-eye) displays deliver information without completely obstructing the user's natural line of sight. They are ideal for complex assembly jobs or when a remote expert needs a first-person view.

-

Tablets and Smartphones: The main advantage is that most team members already own one, making them a low-barrier entry point for AR. Their large screens are well-suited for displaying detailed schematics or intricate 3D models. However, they require at least one hand to operate, which is not ideal for hands-on repairs.

When evaluating options, practicality is key. Durability is non-negotiable; devices must be rugged enough to withstand drops, dust, and moisture. Battery life is also crucial. A device must be able to last a full shift or have hot-swappable batteries to be effective.

Finding the Right Software Partner

If hardware is the vehicle, software is the engine and GPS. It's what makes the hardware useful. There are two main paths: building a custom solution or choosing an established, off-the-shelf platform. For most companies, a platform is the more scalable and practical choice.

A good software solution should serve as a central hub that integrates with your existing systems. Look for platforms that can connect with your CMMS or ERP to automatically pull work orders and asset data. That integration helps shift from a reactive "fix it when it breaks" model to a more data-driven approach. You can explore this philosophy in our breakdown of predictive vs. preventive maintenance.

A truly effective AR software platform doesn't just display information; it connects people and data. It should enable effortless remote collaboration, intuitive creation of digital work instructions, and provide analytics to track performance and identify areas for improvement.

The market for industrial AR hardware is expanding rapidly. In 2021, AR glasses revenue was $1.85 billion. Projections show that number increasing to $23.27 billion by 2025 and reaching $35.06 billion globally by 2026. This reflects widespread adoption in fields where hands-free work provides a significant advantage.

Finally, consider how your team will access information on the plant floor. It's wise to evaluate how well a potential solution can integrate QR codes into AR workflows. A quick scan can instantly pull up all necessary information, turning any piece of equipment into a gateway to its entire maintenance history. The right hardware and software pairing makes this process seamless.

Conclusion: The Future of Maintenance Is Already Here

Augmented reality for maintenance is not a futuristic concept; it is a practical tool solving major operational challenges for companies today. AR bridges the gap between a physical asset and its wealth of digital data, fundamentally changing how frontline teams operate.

We are moving technicians away from paper manuals and guesswork. Instead, we're providing them with instant access to the exact information they need, directly in their line of sight. This is a significant shift that leads to measurable improvements—drastically shorter repair times, higher first-time fix rates, and a safer work environment.

The core benefits are clear: improved efficiency, enhanced safety, and a powerful new method for knowledge transfer that directly addresses the skills gap.

AR Is Becoming the New Standard

The role of augmented reality for maintenance will continue to grow. When combined with other major technologies like the Internet of Things (IoT) and Artificial Intelligence (AI), it creates a truly proactive maintenance ecosystem. Imagine a system where an IoT sensor flags a potential failure, AI predicts the exact breakdown time, and AR guides a technician through the preventive repair before the machine ever goes offline.

This is not just about fixing things faster; it's about transforming maintenance into a strategic, data-led operation rather than a reactive task. AR becomes the user-friendly interface for this intelligent system, turning complex data into simple, actionable steps.

The question for business leaders is no longer if they should adopt AR, but how quickly they can integrate it to remain competitive. A "wait and see" approach is no longer viable. The tools are ready, and early adopters are already realizing a significant return on investment.

For any organization serious about boosting uptime, empowering its workforce, and building a more resilient operation, exploring augmented reality is the logical next step. It is an investment in a smarter, safer, and more productive future that is available now.

Got Questions About AR in Maintenance? We've Got Answers.

When organizations consider bringing augmented reality into their maintenance routines, several practical questions typically arise. It’s natural to wonder about the cost, the learning curve, and how it will integrate with existing systems. Clarifying these details is the first step toward making an informed decision.

Let's address the practical aspects of implementing AR in your maintenance workflow.

So, What's the Real Cost of an AR Maintenance Solution?

Costs can vary significantly depending on the scale of implementation. For a small pilot program using existing tablets or smartphones, the primary cost will be software licenses, which is a low-risk way to begin.

A full-scale rollout for a large team with industrial-grade, rugged smart glasses will require a more substantial investment. The main factors influencing cost are:

- The number of software users.

- The hardware itself. AR devices can range from a few hundred to several thousand dollars per unit.

- Software subscription fees, typically billed monthly or annually.

- Any one-time setup costs for integrating the AR platform with current systems like a CMMS or ERP.

Most companies start with a well-planned pilot project to prove the ROI before committing to a larger deployment.

How Much Training Will My Technicians Actually Need?

You might be surprised. Modern AR platforms are designed for simplicity, so training is usually straightforward. The purpose of AR is to make complex jobs easier, not to add another layer of technological complexity. Most technicians become proficient with a new AR application within a few hours.

The visual overlays and guided, step-by-step instructions create an incredibly short learning curve. Training primarily involves familiarization with the hardware—such as wearing smart glasses—and navigating a simple software interface.

Will AR for Maintenance Work with Our Existing Software?

Yes. Robust integration is a mandatory feature for any serious AR platform. Leading solutions are designed to connect seamlessly with the software you already use, whether that’s a Computerized Maintenance Management System (CMMS), Enterprise Asset Management (EAM), or an ERP system.

This connectivity is essential for the system to function effectively. It allows AR tools to access work orders, review an asset's maintenance history, or display real-time data directly to the technician on the floor. It ensures data consistency across all platforms and prevents your team from having to switch between different applications and devices.

At AIDAR Solutions, we specialize in this technology. We build AR and VR applications that solve real-world operational problems. Our experts can help you design and implement a solution that integrates perfectly with your current systems, empowering your team and delivering a fast return on your investment. Explore our tailored AR solutions today.

Comment(01)