Boost efficiency: reduce downtime in manufacturing today

Before you can begin to tackle downtime, you must gain a clear picture of its true cost. This isn't just about a paused production line; it's a financial drain that spreads through your entire operation, impacting profitability, straining teams, and eroding customer trust.

The True Cost of a Silent Factory Floor

When a machine goes down, the most immediate concern is lost output. While significant, that is only the beginning. The silence on the factory floor creates a ripple effect, and every minute that passes adds to a complex web of direct and indirect costs that many businesses fail to track.

These costs accumulate rapidly. A minor interruption can quickly become a major financial issue. For many industrial manufacturers, an unexpected halt can cost anywhere from $10,000 to $50,000 per hour. The broader perspective is even more significant. According to the Siemens Total Cost of Downtime 2024 report, Fortune Global 500 companies collectively lose an estimated $1.4 trillion every year to unplanned downtime.

Uncovering the Hidden Expenses

To build a solid business case for investing in downtime reduction, you must look beyond the obvious and account for hidden financial drains.

- Labor Inefficiencies: An idle line does not mean an idle payroll. Your skilled operators and technicians are still on the clock, leading to unproductive labor costs. When the line is back up, you are likely paying overtime to compensate for lost time.

- Supply Chain Disruptions: Downtime creates a domino effect. This can lead to contractual penalties for late shipments, premium payments for expedited freight, and strained relationships with suppliers and distributors.

- Reputational Damage: Consistently missing delivery dates erodes customer trust. This can lead to lost contracts and a damaged brand reputation that is difficult and expensive to repair.

The real challenge isn't just fixing the machine; it's containing the fallout. A single hour of downtime is never just sixty minutes lost—it's a multiplier of costs that echoes across the entire value chain.

To provide a clearer idea, here is a breakdown of how these costs accumulate.

Downtime Impact Analysis

This table breaks down the direct and indirect costs associated with unplanned manufacturing downtime, helping decision-makers understand the full scope of the financial impact.

| Impact Area | Description | Example Financial Consequence |

|---|---|---|

| Lost Production | The most direct cost: the value of goods that were not produced during the outage. | $20,000 in lost revenue for a 2-hour stoppage on a high-volume line. |

| Wasted Labor | Wages paid to idle employees who cannot perform their primary tasks. | $5,000 in unproductive payroll for operators and maintenance staff. |

| Overtime Costs | Extra hours required to catch up on production quotas after the line is restored. | $3,000 in overtime pay for a single shift to meet a deadline. |

| Scrap & Rework | Products that are damaged or out of spec during the shutdown or restart process. | $1,500 in scrapped materials and rework labor. |

| Expedited Shipping | Premium fees paid to rush delayed orders to customers to avoid penalties or loss of business. | $2,500 in additional freight charges for an urgent shipment. |

| Reputational Damage | The long-term, intangible cost of lost customer trust and potential future business. | Loss of a $100,000 annual contract due to unreliable delivery schedules. |

As you can see, the financial consequences extend far beyond the initial production halt.

From Cost Center to Strategic Priority

Viewing downtime solely as a maintenance problem is a significant oversight. It is a strategic business issue with a direct impact on profitability and competitiveness. When you add up all the direct and indirect costs, it becomes clear: investing in a smart downtime reduction strategy is not an expense—it is one of the highest-return investments you can make.

To manage these costs, you need to track the right KPIs. For a deeper dive, take a look at our guide on the most important operational efficiency metrics. By putting real numbers to the problem, you can shift the conversation from reactive repairs to proactive improvements that protect your bottom line. This data-driven foundation is exactly what you need to justify implementing advanced solutions that prevent failures before they happen.

Finding the Real Reasons Your Line Stops

To effectively reduce downtime, you must move beyond superficial observations. A machine stoppage is not the root cause; it is a symptom. Logging an event as "equipment failure" is akin to a doctor diagnosing a patient as "sick"—accurate, but unhelpful for treatment. You need a structured method to diagnose the real, often hidden, reasons your production line grinds to a halt.

It begins with a commitment to deeper investigation. Instead of accepting the first explanation, your team needs a framework to analyze the problem systematically. This is where proven root cause analysis methods become invaluable on the factory floor.

Going Beyond the Obvious with Practical Diagnostics

Two of the most effective methods for this are the '5 Whys' and Failure Mode and Effects Analysis (FMEA). While they may sound technical, in practice, they are straightforward and powerful.

The '5 Whys' is a simple yet effective questioning technique. When an issue occurs, you repeatedly ask "Why?" until you uncover the fundamental problem.

- Problem: The conveyor belt stopped.

- Why? The motor overheated.

- Why? The motor bearings weren't properly lubricated.

- Why? The scheduled lubrication was missed.

- Why? The new technician was not trained on that specific machine's lubrication schedule.

- Root Cause: The training process for new maintenance staff is inadequate.

The real problem was a training gap, not just a faulty motor. Fixing the motor resolves the immediate issue, but improving the training program prevents this from recurring on any machine that technician services.

Failure Mode and Effects Analysis (FMEA) is a more structured, proactive approach. It involves systematically reviewing your processes and equipment to identify all potential failure modes, their causes, and their consequences. By scoring each potential failure on its severity, likelihood, and detectability, you can prioritize the biggest risks and prevent downtime before it occurs.

Creating a Clear Downtime Diagnostic Map

A significant step forward is to accurately categorize every downtime event. This transforms raw data into actionable intelligence. Without clear categories, you are essentially guessing. You cannot spot trends or identify the most significant sources of disruption.

Start with some common downtime categories:

- Mechanical Failure: The classic breakdown of belts, motors, pumps, and other components.

- Operator Error: Mistakes made during setup, operation, or changeovers.

- Material Shortages: Production stops due to a lack of raw materials or components.

- Tooling Issues: Problems with jigs, fixtures, or other essential production tools.

- Planned Maintenance: Scheduled stops for upkeep. It is important to track these as well and work to make them more efficient.

To determine why your line stops, the data you collect must be reliable. It is worth exploring how improving data quality for business success can reveal the true culprits. Clean, consistent data is the foundation of any effective analysis.

By meticulously categorizing downtime, you move from a vague list of problems to a clear diagnostic map. This map doesn't just show you where the failures are; it shows you where to focus your resources for the greatest impact.

Establishing KPIs to Measure What Matters

Once you start investigating root causes, you need a way to track whether your solutions are effective. Key Performance Indicators (KPIs) provide the hard numbers to measure your progress. For downtime, the two most critical metrics are Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR).

Mean Time Between Failures (MTBF) indicates, on average, how long a piece of equipment operates before it fails again. A higher MTBF means your equipment is becoming more reliable.

- Formula: Total Uptime / Number of Breakdowns

- Goal: Increase it. A rising MTBF is proof that your reliability efforts are paying off.

Mean Time to Repair (MTTR) measures the average time it takes to restore a machine to operation after it fails. A lower MTTR means your maintenance team is becoming more efficient and effective.

- Formula: Total Downtime for Repairs / Number of Repairs

- Goal: Decrease it. A falling MTTR means you're restoring the line to operation faster.

Tracking these KPIs provides a clear, data-backed report card on your performance. They prove the ROI of new strategies and technologies, transforming your efforts against downtime from guesswork into a measurable, strategic win.

Moving From Reactive Fixes to Predictive Wins

Relying on a 'break-fix' maintenance model is a significant risk in manufacturing. It means you are always one unexpected failure away from a costly production halt. The most effective solution is to shift from reactive problem-solving to proactive prevention, which requires a data-driven approach to maintenance.

This shift is a gradual evolution. The first step is implementing smart preventive maintenance (PM) schedules. Similar to changing the oil in a car, you service equipment at regular, predetermined intervals to prevent known failure modes and extend asset life. It is a foundational step that immediately reduces unexpected breakdowns.

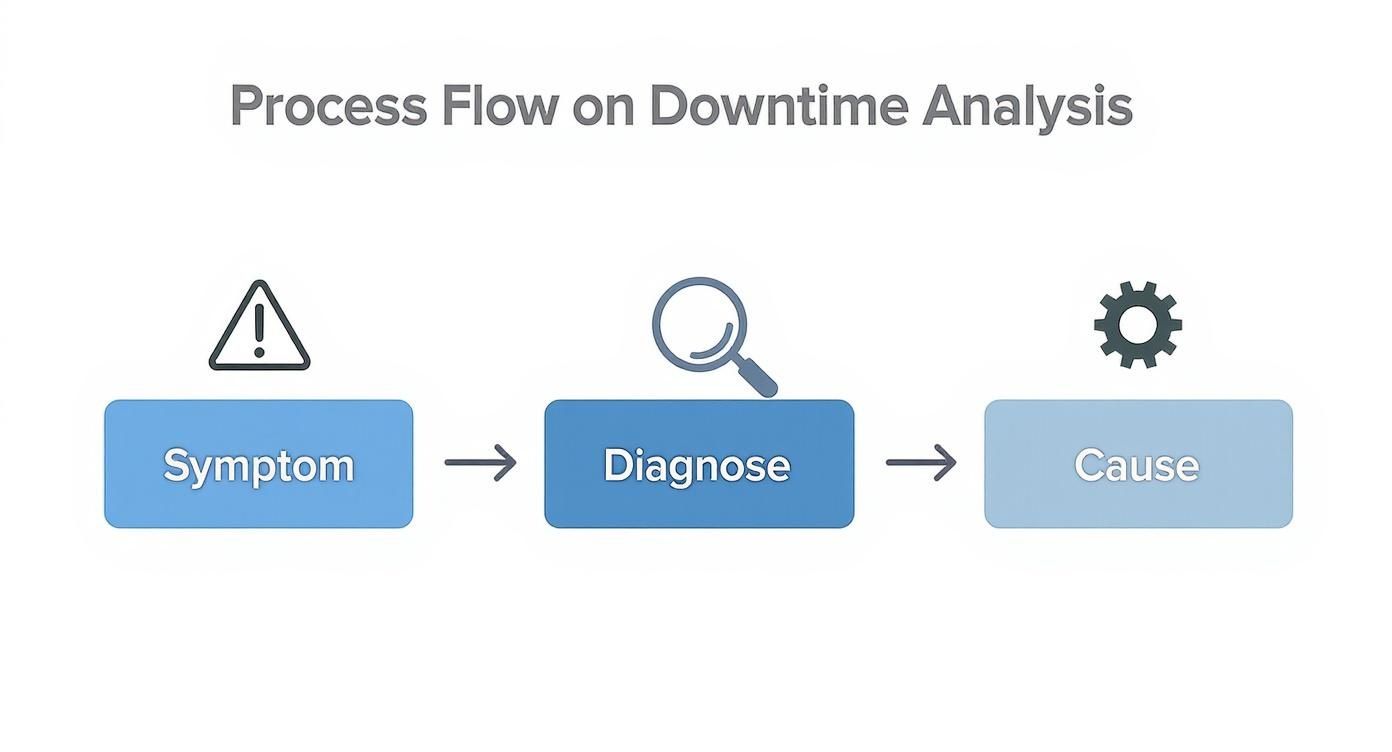

The diagram below shows the basic thought process for analyzing any downtime event. This is the starting point when building a proactive strategy.

Moving from symptom to diagnosis to root cause is critical. It is how you get beyond simple fixes and start understanding what truly needs to be prevented.

Embracing the Future with Predictive Maintenance

Preventive maintenance is a significant improvement over a reactive model, but the real competitive advantage comes from predictive maintenance (PdM). This is where you advance from fixing things on a schedule to fixing them precisely when needed, just before they fail.

PdM uses modern technology to monitor machine health in real time.

- IoT Sensors: These devices are attached to critical equipment, monitoring key health indicators like vibration, temperature, and power consumption.

- AI and Machine Learning: Intelligent algorithms analyze the constant stream of data from these sensors, spotting subtle patterns and anomalies that precede a failure.

For example, a slight increase in a motor's vibration might be unnoticeable to a human operator. However, an AI model can flag it as the earliest sign of bearing wear. This allows the system to schedule a replacement during the next planned stop, long before it can cause a catastrophic failure on the line.

This data-driven foresight transforms your maintenance team. They cease to be a cost center called in for emergencies and become a strategic asset, actively protecting uptime and optimizing production capacity. For a deeper dive, check out our complete guide on predictive maintenance in manufacturing.

The Powerful ROI of a Proactive Strategy

The business case for this transition is compelling. The difference between reactive and proactive maintenance is significant, especially on the bottom line. Research indicates that reactive maintenance costs 3 to 5 times more than a preventive approach when long-term asset damage and the price of downtime are considered. By implementing predictive technology, manufacturers are making real progress in reducing these expenses.

To truly progress from reactive fixes to predictive wins, integrated systems are necessary. This includes understanding the role of specialized ERP Software for Manufacturing Industries, which helps consolidate operational data for better analysis and decision-making.

By forecasting failures, you're not just preventing downtime; you're fundamentally changing the economics of your operation. You extend asset lifespan, optimize labor resources, and eliminate the cascading costs of unplanned stops.

Implementing this tiered approach—starting with solid preventive schedules and then layering on predictive capabilities—is how you make your factory floor more resilient, efficient, and profitable. It is how you stop taking risks with your production schedule and start winning with data.

Empowering Your Team with AR and VR

While predictive analytics and smart maintenance schedules are excellent for machine health, a significant portion of downtime stems from human factors. Human error is a reality on the factory floor. Inadequate training or knowledge gaps can lead to improper machine operation, slow changeovers, and incorrect repairs, all of which halt production.

This is where immersive technologies like Augmented Reality (AR) and Virtual Reality (VR) are making a substantial impact. These are powerful tools for upskilling your workforce, standardizing complex tasks, and bringing expertise directly to the shop floor. Ultimately, they help you reduce downtime in manufacturing by addressing the human element.

Accelerating Skills with Risk-Free VR Training

Training new hires on high-stakes machinery presents a classic challenge. Placing them on a live production line is risky, potentially causing equipment damage and costly mistakes. However, traditional classroom learning often fails to prepare them for the real pressures of the job.

Virtual Reality training bridges this gap. It creates realistic, interactive simulations of your actual equipment and workflows.

- Practice Without Penalty: New operators can run through startup sequences, troubleshoot common faults, and learn complex assembly tasks in a completely safe digital environment. A mistake in VR is a learning opportunity, not a production-halting disaster.

- Muscle Memory Development: Immersive simulations help employees build muscle memory far faster than reading a manual. This dramatically shortens the learning curve, enabling new team members to become productive and confident more quickly.

This approach directly reduces the common and preventable mistakes made by new employees that often cause downtime. A better-prepared team from day one leads to smoother operations.

Driving Accuracy with On-Demand AR Guidance

While VR is ideal for off-the-floor training, Augmented Reality brings digital intelligence directly to your frontline workers during their tasks. AR headsets or tablets overlay digital information—such as instructions, diagrams, or live data—onto their view of the physical world.

This gives technicians hands-free access to the exact information they need, right when they need it, eliminating the need to consult manuals or return to a terminal. A technician can see step-by-step repair instructions displayed directly beside the component they are fixing.

By putting the right information in the right place at the right time, AR removes guesswork and ensures procedures are followed correctly every single time. That consistency is a cornerstone of any effective strategy to reduce downtime in manufacturing.

Consider a technician performing a complex calibration. With AR, they could see digital markers highlighting the correct adjustment points and a real-time data feed showing if the machine is within tolerance. This not only speeds up the repair but also significantly improves the quality of the work, preventing the same issue from recurring. If you wish to explore this further, there are excellent resources covering the benefits of augmented reality for training and on-the-job support.

The Impact on Key Maintenance Metrics

Adopting AR and VR is about driving measurable improvements to the KPIs that matter.

The most significant benefit is a lower Mean Time to Repair (MTTR). By providing technicians with clear, visual guidance, AR helps them diagnose and fix issues much faster. This directly reduces the time your critical assets are offline, providing a substantial boost to your overall equipment effectiveness (OEE). Empowering your people in this way is a critical, and often overlooked, component in building a more resilient and efficient operation.

Connecting Experts Instantly with AR Support

Even with the best training, some problems are too complex for the on-site technician. A critical piece of specialized equipment might fail in a way that only one or two senior experts in the entire company fully understand.

Historically, this situation meant a costly and time-consuming delay.

The expert would need to travel to the site, resulting in hours or even days of lost production time. Meanwhile, the production line remains idle, and the costs of downtime continue to accumulate. This travel delay is one of the most persistent and expensive challenges in manufacturing maintenance. AR-powered remote assistance offers a solution by enabling you to bring that expert's knowledge directly to the machine in seconds.

This is precisely where Augmented Reality-powered remote assistance changes the dynamics of expert support.

The Power of See-What-I-See Technology

AR remote support creates an immediate, interactive connection between an on-site technician and an off-site expert. Using AR smart glasses or a mobile device, the technician can share their real-time point of view with the specialist, regardless of their location.

This "see-what-I-see" technology allows the remote expert to do more than just verbally guide a technician. They can visually direct the entire repair process with high precision.

- Live Annotations: The expert can draw, circle, and place digital arrows directly onto the technician’s field of view, highlighting the exact button to press or the specific bolt to turn. This eliminates ambiguity.

- Document Sharing: If a schematic or manual is needed, the expert can instantly share and display it in the technician's view, providing critical context without diverting their attention from the task.

- Hands-Free Operation: When using smart glasses, the technician's hands remain free to work, which enhances both safety and efficiency during complex repairs.

This technology closes skill gaps instantly. A junior technician, with the real-time guidance of a seasoned expert, can perform tasks that would have previously been beyond their capabilities.

The core benefit is simple but profound: AR transforms a multi-day problem into a solution that can be found in minutes or hours. It completely eliminates travel time as a factor in your Mean Time to Repair (MTTR).

Traditional vs AR-Enabled Remote Support

To fully appreciate the impact, it helps to compare this new approach with traditional methods. The difference in efficiency, cost, and speed is stark.

| Metric | Traditional Support (Phone/Video Call) | AR-Enabled Remote Support |

|---|---|---|

| Resolution Time | Hours to days, heavily dependent on travel. | Minutes to hours, initiated almost instantly. |

| Communication | Purely verbal, prone to misunderstandings. | Visual and interactive, with precise annotations. |

| First-Time Fix Rate | Lower, as miscommunication can lead to errors. | Significantly higher due to clear visual guidance. |

| Expert Travel Costs | High, including flights, hotels, and expenses. | Eliminated, saving thousands per incident. |

| Technician Confidence | Moderate, relies on interpreting instructions. | High, as they receive direct, unambiguous support. |

By adopting this model, you are not just fixing machines faster; you are creating a more agile and knowledgeable workforce.

The ability to access instant expertise helps reduce downtime in manufacturing by ensuring the right person is on the job every time, even from a thousand miles away. For a closer look at the specifics, explore how augmented reality remote assistance is reshaping industrial maintenance workflows. This shift empowers your team, slashes operational costs, and gets your production line moving again with unprecedented speed.

Common Questions About Slashing Manufacturing Downtime

When exploring ways to minimize production stops, many questions arise. Leaders want to know where to begin, how to justify new tools, and what potential obstacles to anticipate. Here are direct answers to the most frequently asked questions, with practical advice to guide your strategy for reducing downtime in manufacturing.

What's the Very First Thing I Should Do?

Before taking any other action, you must get a handle on your data. You cannot fix what you cannot measure. The first and most critical step is to obtain an accurate, data-backed understanding of where your downtime originates.

Start by defining what "downtime" means for your operation. Is it a 5-minute jam? A 30-minute tool change? Be specific. Then, implement a system to track it. This could range from simple manual logs on the factory floor to a comprehensive Manufacturing Execution System (MES). The objective is to capture and categorize every downtime event so you can identify which problems are the most costly.

This baseline data becomes the foundation of your entire improvement strategy. It provides the evidence needed to focus your time and resources where they will have the greatest impact.

How Do I Justify Spending on AR and VR?

Making the case for technologies like Augmented and Virtual Reality depends on demonstrating a clear, quantifiable Return on Investment (ROI). The conversation must shift from technology features to tangible financial outcomes.

Build your business case by first calculating the true costs of your current downtime—lost production value, labor hours for repairs, expert travel expenses, and more. Then, you can project the potential savings.

- For AR remote support: Start with the most obvious benefit—eliminating travel costs for experts. However, the greatest value lies in reducing your Mean Time to Repair (MTTR). Show how much production revenue is recovered for every hour of downtime saved.

- For VR training: You can measure the reduction in training hours for new hires, which is a direct cost saving. Additionally, track the decrease in costly errors made by new employees on the live production line and improvements in safety incidents.

When you can present hard numbers in a meeting—such as a 30% reduction in repair time or a 50% drop in training-related errors—the technology is no longer a "nice-to-have." It becomes a clear financial win that is difficult to dispute.

What Are the Biggest Hurdles in Shifting to Predictive Maintenance?

Transitioning from a routine, schedule-based maintenance plan to a truly data-driven, predictive model is a significant change. It is a powerful move, but it comes with common challenges: technology integration, data quality, and—most importantly—cultural change.

First, integrating new IoT sensors with older, legacy equipment can be technically complex. Do not underestimate the groundwork required to ensure system compatibility and proper data flow.

Second, the effectiveness of any predictive model is determined by the quality of the data it receives. Feeding it incomplete, inconsistent, or irrelevant information will result in unreliable predictions. Ensuring clean data is essential.

Finally, the human element is often the most challenging aspect. You need to shift your maintenance team's mindset from a reactive, "firefighting" culture to a proactive, analytical one. This requires strong leadership, effective training, and clear evidence that the new system makes their jobs easier and more effective. Gaining buy-in from the technicians who will use it daily is crucial.

Should I Start with a Pilot Project or Go All-In?

It is almost always better to start with a pilot project. Attempting a massive, company-wide rollout from the start is risky, expensive, and difficult to manage. A pilot project offers a smarter, more strategic approach.

Select one production line or a specific set of critical machines that are known problem areas. This provides a controlled environment to test your new strategy, technology, and processes on a smaller, more manageable scale, keeping the initial investment and risk low.

A successful pilot does more than just prove the concept; it creates a powerful internal case study. It builds momentum, provides invaluable lessons for a wider rollout, and helps you secure the broad support and budget needed to scale the program across the entire facility.

Ready to empower your team and dramatically cut downtime? AIDAR Solutions provides immersive AR and VR tools that deliver faster training, instant remote expert support, and measurable improvements to your bottom line. Discover how our solutions can transform your operations.