Preventive Maintenance vs Predictive Maintenance: Which Is Better?

The real difference between preventive and predictive maintenance comes down to one thing: timing. Preventive maintenance is time-based, tied to a fixed calendar. Predictive maintenance, on the other hand, is condition-based, triggered only when real-time data says there’s a problem brewing. The right choice for you boils down to a simple question: do you prefer the certainty of a schedule or the precision of data?

Understanding the Core Maintenance Strategies

Picking the right maintenance approach is a huge operational decision. It directly impacts your equipment uptime, how you spend your budget, and your overall efficiency. While both preventive and predictive strategies are designed to keep you out of costly, reactive fire-fighting mode, they are built on entirely different philosophies. Getting a handle on these differences is the first step toward building a maintenance program that actually works for your bottom line.

Preventive Maintenance: The Scheduled Approach

Preventive maintenance (PM) is all about the calendar. It’s a proactive strategy where technicians perform routine checks, lubrications, and part swaps at predetermined intervals—say, every three months or after 500 hours of operation. This happens regardless of how the asset is actually performing.

The beauty of this method is its simplicity. It’s straightforward to implement and budget for, making it a solid choice for less critical equipment or assets with very predictable failure rates. But this scheduled approach has its own built-in waste. PM often means you’re performing maintenance on perfectly healthy equipment, which can be a serious drain on resources. In fact, some studies show that 15-20% of maintenance activities under a purely preventive model can be completely unnecessary.

Predictive Maintenance: The Data-Driven Approach

Predictive maintenance (PdM) is a much smarter, condition-based strategy. Instead of a schedule, PdM uses sensors and data analytics to keep an eye on equipment health in real-time. It’s constantly analyzing variables like vibration, temperature, and acoustics to catch the tiny, subtle signs that signal a future failure. Maintenance only gets scheduled when the data shows it’s actually needed—just before a breakdown.

By focusing on an asset's actual condition, predictive maintenance shifts the conversation from "what might fail" to "what will fail and when." This precision allows organizations to maximize asset lifespan and minimize unnecessary interventions.

This data-first approach allows for surgical precision in your maintenance planning, which in turn optimizes how you use your labor and parts. The goal is to act at the perfect moment—after the first hint of trouble but well before a catastrophic failure. This is absolutely essential when you are looking for ways to reduce operational costs.

Preventive vs Predictive Maintenance At a Glance

To make the choice clearer, it helps to see the two strategies side-by-side. Each has its place, and the best fit depends entirely on your assets, budget, and operational goals.

| Criterion | Preventive Maintenance (PM) | Predictive Maintenance (PdM) |

|---|---|---|

| Trigger | Time or Usage (e.g., every 6 months) | Asset Condition (e.g., vibration spikes) |

| Approach | Proactive but scheduled | Proactive and data-driven |

| Initial Cost | Lower | Higher (sensors, software) |

| Technology | Checklists, basic management software | IoT sensors, AI, machine learning |

| Ideal Use Case | Non-critical, predictable assets | Business-critical, complex machinery |

Ultimately, this table shows a trade-off. PM offers simplicity and lower upfront costs, while PdM provides higher efficiency and long-term savings at the cost of a greater initial investment in technology.

The Proactive Approach of Preventive Maintenance

Preventive maintenance (PM) is all about a simple but powerful idea: fix things before they break. It’s a proactive strategy built on a foundation of scheduled, routine actions—think inspections, cleaning, lubrication, and parts swaps—all done at predetermined times. This calendar-based system replaces guesswork with predictability.

Unlike the reactive “run-to-failure” method, PM is designed to extend an asset's lifespan and drastically cut down on unexpected breakdowns. The core logic is that consistent, scheduled care is far more cost-effective than cleaning up the mess from a catastrophic equipment failure.

Crafting a PM Schedule

The real magic of a solid PM program is in its schedule. These aren't just dates pulled out of a hat; they’re typically built from a mix of reliable sources that give you a solid baseline for how often to perform maintenance.

- Manufacturer Recommendations: Your first stop should always be the Original Equipment Manufacturer (OEM) manuals. They provide crucial guidance on service intervals based on the equipment's design and their own testing.

- Historical Data: Your organization’s own maintenance records are a goldmine. Digging into past failures helps you tailor schedules to your actual operating conditions, not just what the manual says.

- Fixed Intervals: Triggers can be time-based (like inspecting an HVAC unit every three months) or usage-based (like servicing a vehicle every 5,000 miles). The key is to pick the one that most directly correlates with wear and tear on that specific asset.

By weaving these inputs together, organizations create a structured framework that brings order to their maintenance operations. This is a huge differentiator in the preventive maintenance vs predictive maintenance debate.

The biggest advantage of preventive maintenance is how straightforward it is to implement. It gives you a clear, actionable plan that reduces operational chaos without needing complex tech or heavy data analysis.

Benefits and Practical Applications

The practical upsides of PM make it a lasting and popular strategy, especially for certain types of equipment and work environments. Its simplicity makes budgeting, planning, and execution much easier, putting it within reach for companies of all sizes.

A classic use case is fleet management. Commercial trucking companies live and die by their strict PM schedules for oil changes, brake inspections, and tire rotations. It's about ensuring vehicle reliability and meeting safety compliance. A single missed check-up can lead to a costly roadside breakdown and blown delivery deadlines, making the consistency of PM non-negotiable.

Facilities management is another area that leans heavily on preventive schedules. Regularly inspecting fire suppression systems, elevators, and HVAC units isn't just about efficiency—it's about regulatory compliance and keeping people safe. These assets tend to have predictable failure patterns, making them perfect candidates for a time-based approach. Of course, even with a great PM plan, complex issues can still pop up, which is why strong maintenance problem-solving skills are always essential.

The Inherent Drawbacks of a Scheduled System

For all its strengths, the rigidity of preventive maintenance is also its biggest weakness. Because tasks are triggered by a schedule rather than the actual condition of the equipment, it often creates two significant problems.

First, there's the very real risk of over-maintenance. Technicians can spend valuable time and money replacing parts that are still in perfectly good shape, all because the calendar said it was time. This isn’t just a waste of labor and inventory; it also introduces the risk of human error, potentially causing an "induced failure" on an otherwise healthy machine. This inefficiency is a critical point to consider when comparing preventive maintenance vs predictive maintenance strategies for your most important assets.

The Data-Driven Future of Predictive Maintenance

While preventive maintenance runs on a schedule, predictive maintenance (PdM) lives in the world of real-time data and smart forecasting. It’s a massive leap forward, ditching calendar-based checkups for condition-based action. Repairs only happen when an asset’s health actually starts to dip, allowing teams to intercept failures with surgical precision.

At its core, PdM uses a network of sensors and advanced tech to paint a live picture of equipment health. Instead of waiting for a reminder, it’s always listening for the subtle whispers of impending trouble. This lets teams act at the perfect moment—right after a problem is detected but long before it can cause a catastrophic breakdown.

The Technology Powering Prediction

Predictive maintenance isn't just one tool; it's a whole ecosystem of technologies working in sync. This synergy is what turns raw data into smart, actionable maintenance plans, making the entire operation more intelligent and responsive.

It all starts with Internet of Things (IoT) sensors embedded right into the machinery. These sensors are the system's eyes and ears, constantly collecting huge streams of operational data. Some of the most common types include:

- Vibration Analysis: Catches imbalances, misalignments, or bearing wear in any rotating equipment.

- Thermal Imaging: Spots overheating in electrical parts or friction points before they can fail.

- Acoustic Analysis: Listens for abnormal sounds—like grinding or clicking—that point to internal damage.

- Oil Analysis: Measures contaminants or chemical changes in lubricants to get a clear read on engine health.

This steady flow of information is fed into sophisticated machine learning (ML) and artificial intelligence (AI) algorithms. These algorithms chew through historical and real-time data to find the hidden patterns that precede failures. They effectively learn what "normal" looks like and immediately flag any deviation. But collecting data is only half the battle. The real power comes from turning it into clear insights through robust analytics and data visualization.

Maximizing Uptime and Asset Lifespan

The biggest win from a well-run PdM program is the massive drop in unplanned downtime. By forecasting failures, companies can schedule repairs during planned shutdowns, keeping production humming. For asset-heavy industries like manufacturing and aerospace, this is a total game-changer.

Think about it: an airline can use vibration sensors on a jet engine to predict a bearing failure weeks in advance. This allows them to schedule the replacement during routine overnight maintenance. In the same way, a smart factory can use thermal imaging to catch a motor that's starting to overheat, letting them fix the issue before it grinds the entire production line to a halt. This approach to https://aidarsolutions.com/condition-monitoring-and-predictive-maintenance/ keeps critical assets online when they’re needed most.

The core shift with predictive maintenance is moving from asking 'what might fail?' to definitively answering 'what will fail, and when?' This level of foresight allows organizations to manage critical assets with unparalleled confidence and efficiency.

Emerging in the 2000s alongside better sensor technology, PdM has more than proven its worth. Data from top industrial firms shows that adopting this strategy can slash unplanned downtime by up to 50% and cut maintenance costs by 25-30%. Better yet, because repairs are timed perfectly to prevent severe damage, asset lifespans can be extended by 20%. Many early adopters report seeing a full return on their investment in just one to two years. This data-driven precision is what truly sets it apart in the preventive maintenance vs predictive maintenance debate, offering a clear path to optimizing both performance and profit.

Comparing Key Operational and Financial Metrics

When you're weighing preventive maintenance against predictive maintenance, the decision often boils down to the numbers. Both strategies are designed to get you out of the reactive repair cycle, but they hit your operational and financial metrics in fundamentally different ways. This isn't just a tech choice—it's about balancing upfront investment with long-term gains.

To get a true picture, you absolutely need efficient job and cost tracking solutions. Without solid data on labor hours, parts, and the real cost of downtime, you're just guessing.

Initial Investment and Implementation Complexity

Preventive maintenance (PM) is the easier path to get started. The barrier to entry is low, with minimal initial investment. You're mostly looking at the cost of creating maintenance schedules, training staff on routine checks, and maybe a basic management software. Implementation is pretty straightforward since it's built on OEM guidelines and historical data.

Predictive maintenance (PdM), on the other hand, requires a serious upfront capital commitment. The shopping list is long: IoT sensors, data acquisition hardware, advanced analytics software, and significant team training. The implementation is also far more complex, involving data integration, algorithm development, and a major cultural shift toward trusting the data.

While the initial price tag for PdM is high, the long-term financial payoff often justifies the cost, especially for your most critical assets. The trick is to look at the total cost of ownership, not just the upfront expense.

Impact on Downtime and Labor Requirements

How each approach handles equipment downtime is where you'll see a massive difference. PM certainly cuts down on unexpected breakdowns compared to just fixing things when they break, but it also brings planned downtime for scheduled maintenance. This can mean taking perfectly good machines offline, which feels like a waste and disrupts production.

PdM is built to slash both unplanned and unnecessary planned downtime. By forecasting failures, you schedule maintenance only when it's truly needed, often during off-peak hours. This targeted approach means your labor and resources are used with maximum efficiency—technicians are only working on equipment that genuinely needs attention.

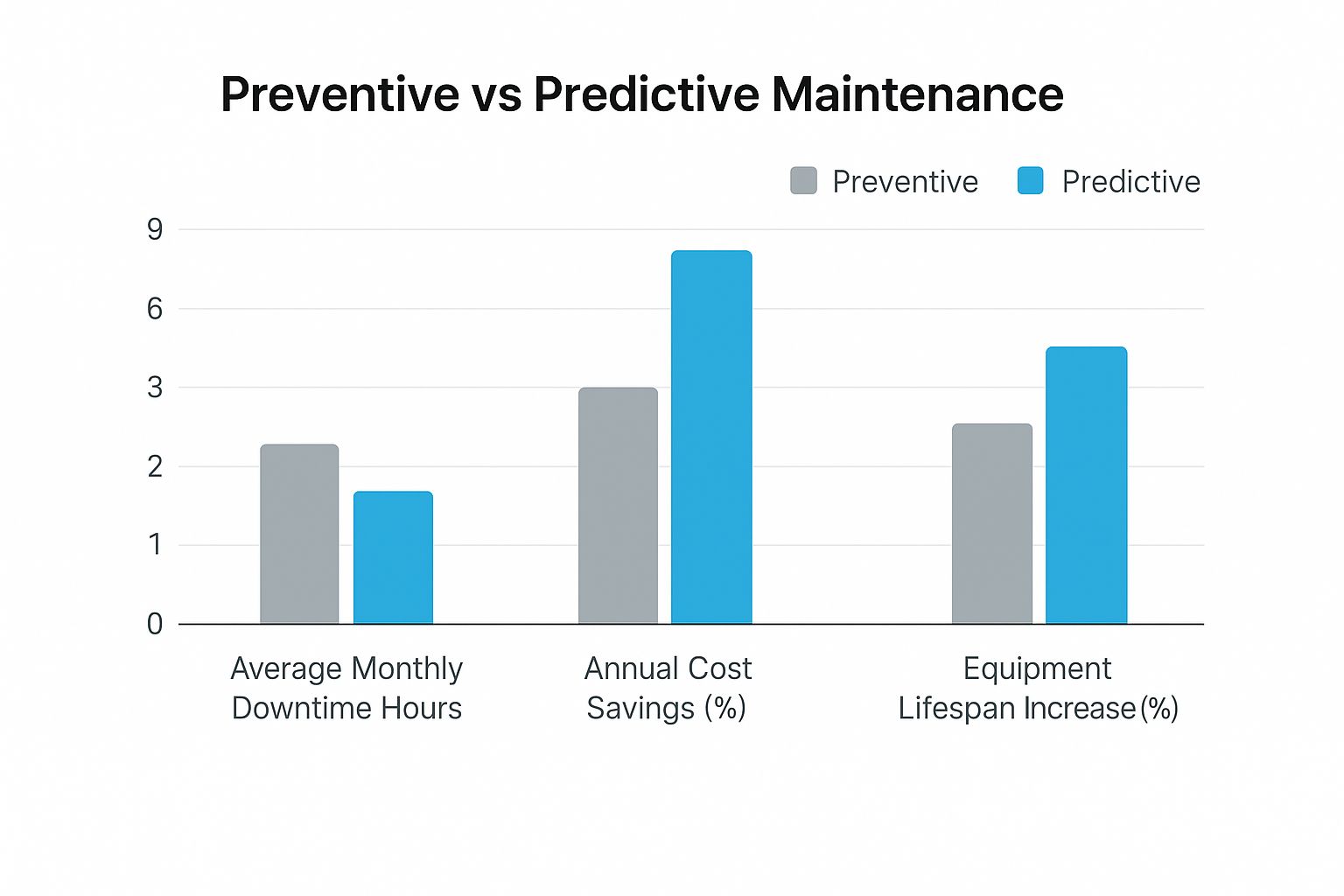

This is where the impact becomes crystal clear.

The data speaks for itself. While both methods are proactive, the surgical precision of predictive maintenance delivers far better results in cutting downtime and stretching the life of your assets.

Long-Term ROI and Cost Savings

Look at the long-term financial picture, and the gap between preventive and predictive maintenance widens considerably. PM delivers its ROI by helping you dodge the huge costs of catastrophic failures and emergency repairs. Its fixed-schedule nature, however, can lead to a lot of waste.

It's not uncommon for over-maintenance to eat up 30% of all maintenance costs in a PM-heavy environment. You're essentially spending money to "fix" things that aren't broken.

In stark contrast, well-executed predictive maintenance programs have been shown to deliver up to a 25% reduction in maintenance costs and a 35% reduction in downtime. Schneider Electric even reported that companies adopting PdM saw their overall equipment effectiveness (OEE) jump by an average of 10-15%.

This is the core philosophy of PdM in action: fix the right part at the right time. By cutting out unnecessary maintenance, optimizing your spare parts inventory, and deploying labor intelligently, PdM provides a powerful and sustainable return on investment that just keeps growing.

Detailed Operational and Financial Metric Comparison

To really dig into the weeds, let's look at a side-by-side breakdown of how PM and PdM stack up against key business metrics. This table lays out the practical differences you can expect to see in your operations and on your balance sheet.

| Metric | Preventive Maintenance (PM) | Predictive Maintenance (PdM) | Key Consideration |

|---|---|---|---|

| Upfront Cost | Low. Primarily scheduling software and training. | High. Requires sensors, software, and data science expertise. | PdM is a capital investment; PM is an operational expense. |

| Downtime | Reduces unplanned downtime but introduces planned downtime. | Minimizes both unplanned and planned downtime. | PdM maximizes asset availability by avoiding unnecessary shutdowns. |

| Labor Efficiency | Lower. Technicians perform routine checks regardless of need. | Higher. Labor is deployed precisely when and where needed. | PdM focuses skilled labor on high-value, data-informed tasks. |

| Spare Parts | Higher inventory required to support a fixed schedule. | Optimized. Parts are ordered just-in-time based on failure predictions. | PdM significantly reduces carrying costs for spare parts. |

| Asset Lifespan | Can extend lifespan but may cause wear from over-servicing. | Maximizes lifespan by addressing issues before they cause major damage. | PdM helps you get the absolute most out of every asset. |

| Return on Investment (ROI) | Moderate and steady. Achieved by avoiding major failures. | High but long-term. Achieved through systemic cost reduction and efficiency gains. | The ROI for PdM accelerates over time as the model learns. |

Ultimately, the right choice depends on the criticality of your equipment and your long-term financial strategy. While PM offers a solid, accessible starting point, PdM provides a path to operational excellence and significant competitive advantage.

How XR Solutions Enhance Maintenance Operations

The preventive vs. predictive maintenance debate often comes down to timing and data. But a new wave of technology is adding a powerful new dimension to both sides of the argument. Extended Reality (XR)—which covers both Augmented Reality (AR) and Virtual Reality (VR)—is a genuine force multiplier, making technicians faster, more accurate, and safer no matter which maintenance philosophy they're using.

Instead of just telling technicians what to do, XR shows them exactly how to do it. These tools are the bridge between a mountain of digital information and the physical piece of equipment right in front of you, turning complex procedures into guided, interactive walkthroughs. It’s fundamentally changing how maintenance gets done.

Augmenting Preventive Maintenance Tasks

For preventive maintenance (PM), which is all about structured, repeatable tasks, Augmented Reality delivers huge practical value. AR overlays digital instructions, checklists, and diagrams directly onto a technician’s view of the equipment, creating a workflow that’s far more intuitive and way less prone to error.

Imagine a junior technician performing a multi-point inspection on a complex machine. Rather than flipping through a dense paper manual, they can use an AR headset or tablet to see precisely which bolts to tighten, which gauges to check, and in what order.

This approach brings some key wins:

- Reduced Error Rates: Step-by-step visual guidance ensures no critical checks are skipped. This boosts the quality and consistency of every scheduled job.

- Faster Training: New hires can get up to speed much quicker by following interactive guides, meaning they don't have to lean on senior staff for every little PM task.

- Improved Safety: AR can highlight high-voltage areas or dangerously hot surfaces, keeping technicians aware of potential hazards in real time.

By transforming a static checklist into a dynamic, interactive guide, AR makes preventive maintenance more engaging and effective. It helps ensure that routine tasks are performed correctly every single time, which is the ultimate goal of any PM program.

Visualizing Predictive Maintenance Data

Predictive maintenance (PdM) is all about data, but raw numbers streaming from sensors can be almost impossible to make sense of on a busy factory floor. This is where AR creates a powerful link between the data and the asset itself. It lets technicians see an asset’s health right on the equipment.

For example, a technician could look at a motor and see a real-time thermal map from its temperature sensors, instantly spotting an overheating component. Or they might see live vibration data shown as a color-coded aura, with bright red indicating a bearing that's about to fail.

This immediately turns abstract data points into something you can act on. To get a deeper look at how this technology is being applied, you can explore the benefits of augmented reality for maintenance and see what's possible. This "digital twin" overlay makes it far easier to pinpoint the source of a problem without any guesswork.

Better yet, when a predictive alert does get triggered, a remote expert can use AR to see exactly what the on-site tech is seeing. The expert can then draw on the technician’s field of view, circling specific parts or pulling up schematics to guide the repair. This capability dramatically improves first-time fix rates, a key metric for any maintenance team. In the end, XR elevates both strategies, making technicians smarter and more capable on the job.

Making the Right Choice for Your Organization

So, preventive or predictive maintenance? It’s not a simple showdown. The smartest play isn't picking one over the other but knowing when to use the right tool for the right job. A one-size-fits-all plan is a recipe for wasted resources; the best approach is always tailored to your specific operational reality.

The whole decision boils down to four key pillars: how critical the asset is, the fallout if it fails, what your budget looks like, and your team's current skills. Looking at your equipment through this lens helps you build a maintenance roadmap that’s both effective and financially sound.

Aligning Strategy with Asset Criticality

First things first, you need to map out your assets based on how vital they are. Not every piece of equipment is a make-or-break component, and your maintenance budget should absolutely reflect that. A quick bit of categorization can bring a ton of clarity.

For low-cost, non-critical, or redundant assets—think a backup water pump or an office HVAC unit—preventive maintenance (PM) is almost always the most sensible and cost-effective route. The financial and operational risk of failure is low, so the simplicity and smaller upfront cost of a scheduled PM program just makes sense. The goal here is solid reliability without overspending.

On the flip side, for that high-value, production-critical machinery where failure means catastrophic downtime and a massive financial hit, predictive maintenance (PdM) is the clear winner. That initial investment in sensors and analytics might seem steep, but it's nothing compared to the immense cost of an unexpected breakdown.

The most effective maintenance programs are never purist. They're pragmatic. They apply a sophisticated, data-driven PdM strategy to mission-critical assets while relying on the predictable structure of PM for everything else.

Embracing a Hybrid Maintenance Model

This reality naturally leads to the most practical solution out there: a hybrid approach. This blended strategy lets you funnel your resources with maximum efficiency, applying the right level of oversight exactly where it's needed most. You get the best of both worlds—without the pointless expense of sticking advanced sensors on every single asset.

Putting a hybrid model into action is a strategic rollout:

- Pinpoint Critical Assets: Start by applying PdM to the top 10-20% of your most critical equipment—the machines whose failure would bring production to a grinding halt.

- Stick with PM for the Rest: Keep a solid PM schedule running for the majority of your other assets. This ensures they get consistent, reliable care.

- Iterate and Grow: Once you start seeing the ROI from your initial PdM rollout, you can gradually expand the program to cover other semi-critical assets.

This tiered approach lets you tap into the power of predictive insights on your most important gear while maintaining operational stability across the board with a proven, schedule-based system. Ultimately, the preventive maintenance vs predictive maintenance debate isn't about choosing a winner—it's about building a smarter, blended strategy that fits your organization’s unique DNA.

A Few Common Questions

When you get down to the brass tacks of preventive vs. predictive maintenance, a few questions always pop up. Let's clear the air on some of the most common ones.

Can a Company Use Both Maintenance Strategies?

Not only can they, but they absolutely should. The most practical and financially savvy approach is almost always a hybrid model. Sticking to just one strategy is rarely the right move. After all, it doesn’t make sense to install expensive sensors on a non-critical asset that’s cheap and easy to replace.

A smart hybrid strategy applies predictive maintenance (PdM) to your most valuable, production-critical machinery—the equipment where any unplanned downtime would be a complete disaster. For everything else—the lower-risk or redundant assets—a scheduled preventive maintenance (PM) program is still the most cost-effective choice. This blended approach makes the most of your resources, ensuring the highest level of monitoring is reserved for the equipment that truly needs it.

What Are the Biggest Challenges of Implementing Predictive Maintenance?

Moving to a predictive model isn't just about buying new tech; it's a major operational and cultural overhaul. The hurdles usually fall into a few key areas:

- High Initial Investment: Let's be honest, the upfront cost for IoT sensors, data analytics software, and the necessary integration can be pretty steep.

- Data Infrastructure: You need rock-solid systems to collect, store, and process the enormous amount of data that sensors generate.

- The Skill Gap: A successful PdM program hinges on having data scientists and analysts who can actually interpret the data and build accurate predictive models. Many teams just don't have this expertise in-house.

- Change Management: This is often the biggest mountain to climb. You have to shift your team's mindset from a familiar, schedule-based routine to a new, data-driven one. Getting seasoned technicians to trust the algorithms takes time and effort, but it's absolutely critical for the program to stick.

Successfully implementing a predictive maintenance program is less about technology and more about building a data-first culture. It requires a commitment to training, process change, and trusting data to guide operational decisions.

How Do You Calculate ROI for Switching to Predictive Maintenance?

Figuring out the return on investment (ROI) for a move from PM to PdM means you have to track specific metrics to weigh the financial gains against that initial investment. At its core, the calculation compares the total cost of the new PdM program with the savings it creates.

Here are the key metrics you’ll want to track:

- Reduction in Unplanned Downtime: Measure the decrease in lost production hours and the revenue that goes with it.

- Lower Maintenance Costs: Keep an eye on savings from fewer labor hours (no more unnecessary checks) and a more optimized spare parts inventory.

- Increased Asset Lifespan: Put a number on the value of extending the operational life of critical equipment before it needs to be replaced.

The formula is pretty straightforward: (Gains from PdM – Cost of PdM) / Cost of PdM. A positive ROI proves that this data-driven approach isn't just an operational upgrade—it's a powerful financial strategy.

At AIDAR Solutions, we specialize in using AR and VR to make your maintenance teams more efficient and accurate, whether you're refining a preventive schedule or visualizing predictive data. Discover how our immersive solutions can elevate your maintenance strategy by visiting https://aidarsolutions.com.