Maintenance in Manufacturing: A Proactive Guide to Uptime and Cost Reduction

When people hear "maintenance," they often picture a mechanic with a wrench fixing a broken machine. But in modern manufacturing, that’s only a tiny part of the story. True maintenance is about getting ahead of the problem—it's the strategic game of keeping your equipment in peak condition to sidestep breakdowns altogether.

It’s a fundamental shift from reactive fire-fighting to proactive, intelligent care. This approach has a massive impact on everything that matters on the factory floor: your profitability, your efficiency, and most importantly, the safety of your people. A solid maintenance program is what stops you from hemorrhaging cash during unplanned downtime and helps you squeeze every last drop of value from your critical machinery.

Why Maintenance Is Your Secret Weapon in Manufacturing

Stop thinking of maintenance as just another cost on the balance sheet. In today's hyper-competitive world, it’s one of the most powerful advantages you can have. A well-oiled maintenance strategy is the engine that drives operational excellence, transforming a chaotic, reactive plant into a smooth, predictable, and highly profitable operation.

Think of your production line like a Formula 1 car. Winning isn't just about having the fastest car on race day. It’s about the elite pit crew that meticulously inspects, tunes, and reinforces every single component before it has a chance to fail on the track. That’s the heart of maintenance in manufacturing today. We’re moving far beyond the old "if it ain't broke, don't fix it" mentality and into a world of smart, data-driven strategies that see problems coming from a mile away.

The True Impact of Proactive Maintenance

When you start treating maintenance like the strategic powerhouse it is, the benefits ripple out across the entire business. It's less about scrambling to fix emergencies and more about fine-tuning a high-performance machine. The goals are simple but incredibly powerful:

- Maximize Uptime: Every single minute your line is down, you’re losing money. Proactive maintenance keeps machines running like clockwork, so you hit your production targets without those soul-crushing interruptions.

- Enhance Operational Efficiency: A well-cared-for machine doesn't just run—it runs better. It uses less energy, produces higher quality products, and creates less scrap. This is a direct shot in the arm for your Overall Equipment Effectiveness (OEE).

- Improve Workplace Safety: Let's be honest, equipment failures are a primary cause of accidents. A structured maintenance plan catches and fixes potential hazards before anyone can get hurt.

By making maintenance a priority, a facility flips the script. Instead of emergencies running the show, you're in a state of control, predictability, and continuous improvement. That's the new standard.

This guide is your roadmap to getting there. We'll walk through the different strategies, from the foundational preventive tactics to the more advanced predictive technologies. The end game? To give you the tools and knowledge to turn your maintenance department from a cost center into a core driver of your company's bottom line.

Understanding Your Core Maintenance Strategy Options

Navigating the world of manufacturing maintenance can feel overwhelming, but it really just boils down to a handful of core philosophies. The easiest way to think about them is to compare them to your own health—each strategy represents a different level of foresight and intervention. Getting these straight is the first step to building a more resilient, profitable operation.

The most basic approach is reactive maintenance. This is the "run-to-failure" model, and it’s exactly like waiting for a health emergency before you even think about calling a doctor. You only fix equipment after it breaks down. While this demands almost no upfront planning, it’s a recipe for disaster, often leading to catastrophic failures, sky-high emergency repair bills, and painful, unplanned downtime. It’s the factory equivalent of emergency surgery—disruptive and incredibly expensive.

From Scheduled Check-Ups to Proactive Care

A much more structured approach is preventive maintenance (PM). Think of this as your facility's annual physical. Maintenance tasks are scheduled based on a set calendar or usage hours, regardless of the machine's actual condition at that moment. The entire goal is to catch small issues before they snowball into major failures.

This strategy is everywhere. In fact, preventive maintenance is the dominant approach in manufacturing, with up to 90% of industrial facilities using it as a cornerstone of their plan. But there's a catch: its success depends on flawless execution, which is a major time sink, demanding an average of 33 hours every week per plant just to manage.

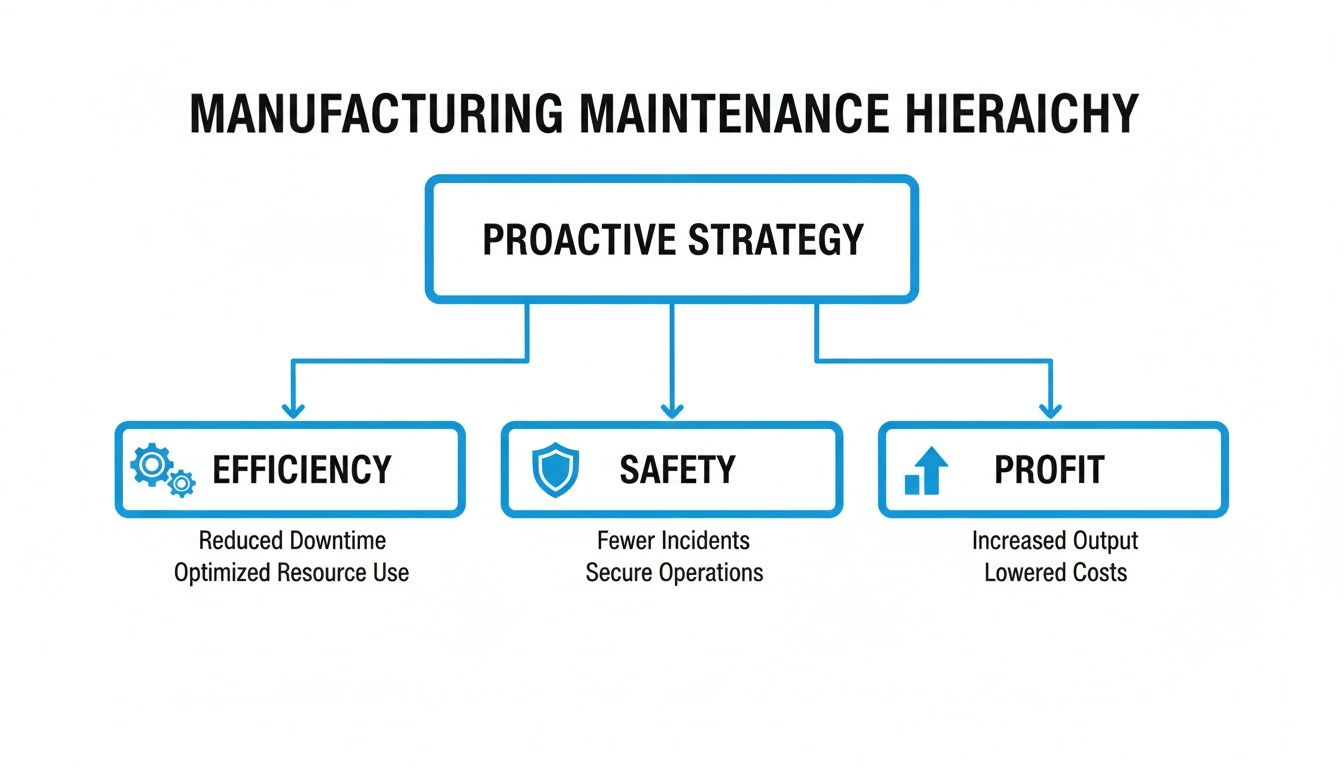

The diagram below really drives home how shifting toward a more proactive strategy directly impacts the bottom line.

As you can see, a proactive mindset isn't just a buzzword; it's the foundation for driving efficiency, locking in safety, and boosting overall profit.

To help you weigh your options, here’s a quick breakdown of how these strategies stack up against each other.

Comparison of Maintenance Strategies

| Strategy | Trigger | Cost Profile | Best For |

|---|---|---|---|

| Reactive | Equipment Failure | Low upfront, very high long-term | Non-critical assets where failure has minimal impact. |

| Preventive | Fixed Schedule (Time/Usage) | Moderate and predictable | Critical equipment with known failure patterns. |

| Condition-Based | Real-time Asset Condition | Higher upfront (sensors), lower long-term | Assets where condition data is easily monitored. |

| Predictive | AI-based Forecasts | Highest upfront (tech/data), lowest overall | High-value, critical assets where downtime is unacceptable. |

Each approach has its place. The key is to find the right blend for your specific needs, assets, and goals.

Listening to Your Equipment's Health Signals

Beyond fixed schedules, we get into more dynamic strategies. Condition-based maintenance (CBM) is like monitoring your body's vital signs. Instead of a routine check-up, you take action when a specific indicator—like a sudden fever—signals something is wrong. In a factory, this means using sensors to track things like vibration, temperature, or oil quality in real time.

Maintenance work is only triggered when the data shows a part is starting to degrade or operate outside its normal range. This approach brilliantly avoids unnecessary servicing, making sure you only spend time and money when and where it's truly needed. It's a much smarter, more targeted way to manage asset health.

Predicting the Future of Machine Health

Finally, we have the most advanced strategy: predictive maintenance (PdM). Think of this as genetic screening for your machines, forecasting future health risks so you can act long before any symptoms appear. PdM uses powerful tools like IoT sensors and AI to analyze massive streams of real-time and historical data, spotting the faint, subtle patterns that always precede a failure.

Predictive maintenance doesn't just tell you that a part is wearing down; it predicts when it is likely to fail, allowing teams to schedule repairs with incredible precision during planned downtime.

This data-driven forecasting all but eliminates surprise breakdowns and helps you squeeze every last drop of useful life out of your components. It’s the pinnacle of proactive maintenance in manufacturing, turning asset management from a guessing game into a precise science.

To really dig into how these two proactive strategies compare, you can check out our guide on predictive vs. preventive maintenance. Each of these four strategies can be the "right" one—it all depends on your operational maturity, which assets are most critical, and what your ultimate business goals are.

The Real Costs Lurking Behind Common Maintenance Challenges

Every plant manager knows that gut-wrenching feeling when a production line grinds to a halt. But the true cost of a shaky maintenance strategy runs much deeper than just the immediate production loss. Sticking with outdated maintenance in manufacturing isn't just inefficient—it's a silent killer for your bottom line, creating hidden expenses that bleed you dry.

These problems show up in ways both obvious and subtle. You’ve got the massive financial haymaker of unplanned downtime on one hand, and the slow, creeping death from outdated administrative processes on the other. In today's competitive market, ignoring these issues simply isn't an option anymore.

The Financial Drain of Unplanned Downtime

Unplanned downtime is the most glaring—and painful—symptom of a maintenance strategy that’s failing. It’s never just about one machine being idle. It’s a catastrophic chain reaction that ripples through the entire operation, leading to missed deadlines, angry customers, overtime pay, and rush shipping costs for replacement parts.

The financial toll is staggering. For Fortune Global 500 companies, unplanned downtime eats up a shocking 11% of their yearly turnover, on average. When you consider that equipment downtime can cost as much as $260,000 per hour, you can see why manufacturers in automotive, aerospace, and heavy machinery are desperate for a better way. Learn more about the latest maintenance statistics.

When a critical asset fails, the real cost isn't the price of a replacement part. It's the lost revenue, the damaged client relationships, and the frantic, all-hands-on-deck scramble to get back on track.

This kind of financial hemorrhage makes it crystal clear: the old "fix-it-when-it-breaks" model has to go. The only way forward is a proactive approach that sees failures coming and stops them before they can wreak havoc on the factory floor.

The Widening Skills Gap

Here’s another storm brewing on the horizon: the skills gap. As waves of veteran technicians—the ones with decades of tribal knowledge—head off into retirement, they take all that priceless experience with them. This leaves a younger, less seasoned workforce trying to figure out increasingly complex machinery.

A common scenario involves flying a senior expert across the country for a 30-minute fix that a junior technician on-site could have handled with the right guidance. This isn’t a hypothetical scenario; it's a recurring, expensive reality for too many organizations. The costs just pile up:

- Travel Expenses: Flights, hotels, and per diems for your top people.

- Lost Opportunity: While that expert is traveling, they aren't available for other high-value tasks.

- Extended Downtime: The machine sits idle for hours, or even days, just waiting for the expert to arrive.

Relying on a shrinking pool of experts creates a massive operational bottleneck. It shines a spotlight on the desperate need for better knowledge-sharing and remote support tools. Without them, every simple problem has the potential to blow up into a major, costly crisis.

The Hidden Inefficiencies of Outdated Workflows

Finally, let's talk about the paper problem. So many maintenance teams are still drowning in paper-based processes. Manual work orders, paper checklists, and dusty binders full of technical manuals aren't just clunky—they're magnets for inefficiency and human error.

These old-school workflows create a host of issues that directly torpedo performance. Technicians burn valuable time hunting for the right manual or trying to make sense of illegible scribbles from a previous shift. A small but critical task that often gets missed in paper-based systems is ensuring proper secondary container labeling for workplace safety, which can lead to huge compliance headaches.

Without any digital integration, there’s no easy way to track historical data, spot recurring issues, or analyze performance trends. You're left with a maintenance operation that’s always playing catch-up, completely unable to learn from past failures or get ahead of future ones.

How Technology Is Changing the Game on the Factory Floor

After getting burned by the high costs and operational drag of old-school maintenance, it’s obvious something has to change. The good news? A whole new wave of technology is turning maintenance in manufacturing from a reactive guessing game into something more like a precise, data-driven science. These tools are giving teams the power to practically see the future, act with precision, and keep the whole operation running smoother than ever.

Leading the charge is Predictive Maintenance (PdM). The best way to think about it is like installing a smart nervous system across your entire factory floor. This system uses a web of Internet of Things (IoT) sensors to constantly listen in on the health of your most important machines, catching the faintest whispers of trouble.

It’s not so different from a smart thermostat that learns your home’s heating and cooling habits to keep things efficient and comfortable. In the same way, PdM systems learn the unique operational signatures of your equipment—its normal vibrations, temperatures, and pressures—to predict a problem long before it becomes a full-blown, catastrophic failure.

The Power of Looking Ahead

Predictive maintenance isn’t just some futuristic concept; it’s delivering real, measurable wins on factory floors right now. By bringing together IoT, artificial intelligence, and smart sensors, 85% of teams say they’ve gotten much better at forecasting downtime.

The knock-on effect on operations is huge. Studies show that 91% of plants have cut their repair times and slashed unplanned outages, while 93% are getting a better handle on their aging equipment.

This kind of tech fundamentally changes how decisions get made. Instead of just following a calendar or waiting for an alarm to go off, maintenance teams are now guided by smart, data-backed advice. That shift, from just-in-case servicing to as-needed intervention, is a true game-changer for managing resources and getting the most life out of your assets.

Augmented Reality: The Human Connection for Complex Data

All this predictive data is incredibly powerful, but it’s only useful if your frontline crews can actually understand it and act on it. This is exactly where Augmented Reality (AR) and Virtual Reality (VR) come in. They serve as that critical human interface, translating dense machine data into clear, visual instructions.

AR solutions perfectly blend the digital and physical worlds. Picture a technician wearing smart glasses who can look at a complex machine and see digital information overlaid right on top of it. This tech can provide:

- Real-time data at a glance: Technicians can see live performance numbers like temperature or pressure right on the machine itself, no need to run back to a monitor.

- Step-by-step visual guides: Complex repair jobs can be shown as 3D animations and visual prompts, walking the user through every single task with pinpoint accuracy.

- On-demand expert help: A junior tech can stream what they're seeing to a senior expert anywhere in the world. That expert can then provide annotations on screen to point out specific parts or guide them through a tricky fix.

AR and VR don’t replace skilled technicians; they make them better. These tools put the right information, in the right place, at the exact moment it’s needed. This drastically cuts down on human error and slashes the time it takes to get a job done.

Virtual Reality takes things even further by creating completely immersive, simulated training worlds. Technicians can practice difficult or dangerous repairs on a perfect digital twin of a machine. This lets them build crucial skills and muscle memory in a totally safe environment, without risking damage to multi-million dollar equipment or causing production to grind to a halt.

When you combine predictive data with these immersive tools, you’re not just fixing machines—you’re creating a smarter, faster, and more empowered maintenance workforce. For a wider look, check out our article on how new technologies in manufacturing are making an impact across the board.

Solving Your Toughest Maintenance Problems with AR

This is where the theory of tech-driven maintenance gets real. Augmented Reality (AR) and Virtual Reality (VR) aren’t just futuristic concepts from a trade show; they are practical tools being put to work on the factory floor right now, solving the stubborn, costly problems that bring production to a grinding halt.

By laying digital information over the real world, AR gives your technicians the exact knowledge they need, right when and where they need it. This fundamentally changes how people interact with complex equipment, transforming a flood of data into simple, actionable steps. But it's not about just buying headsets; a solid digital transformation strategy is the key to making sure these tools actually align with your business goals and empower your existing workforce.

Remote Expert Assistance When Every Second Counts

Let’s be honest, this scenario is all too common: a critical machine is down, and the one person who really knows how to fix it is hundreds of miles away. The old way of doing things meant expensive flights, hotel stays, and days of painful downtime.

With AR, that entire problem just vanishes. A junior technician on-site can pop on a pair of smart glasses and stream their exact point-of-view to a senior engineer sitting comfortably in their office. The expert sees what the tech sees and can walk them through the entire repair in real-time. They can even provide on-screen annotations, circling the right component or popping up a schematic right in the technician's line of sight.

The result? A problem that used to take days and thousands of dollars to fix is now solved in minutes. It's a massive blow to your Mean Time to Repair (MTTR), and it gets your line moving again, fast.

This is also a huge win for bridging the skills gap. It lets your most seasoned veterans mentor multiple junior techs at once, effectively cloning their expertise across the entire operation.

AR-Guided Workflows for Flawless Execution

Beyond just calling for help, AR offers guided digital workflows that standardize complex tasks and virtually eliminate human error. Instead of flipping through a greasy paper manual or squinting at a 2D diagram on a tablet, a technician sees the instructions layered right onto the machine itself.

Picture a tech performing a delicate calibration. Through their AR headset, they’d see:

- Step-by-step prompts appearing one by one as they complete each action.

- 3D holographic arrows pointing to the exact bolt that needs tightening or the lever that needs adjusting.

- Live data readouts from the machine's sensors, confirming a part is within tolerance before they even move on.

This approach makes sure every procedure is done right, the same way, every single time. It dramatically speeds up the work and is an incredible tool for training new hires, getting them to perform complex jobs with the confidence of a seasoned pro. For a deeper dive, check out our piece on augmented reality for maintenance.

Safe and Scalable Training with Virtual Reality

While AR enhances work on the real factory floor, Virtual Reality (VR) creates a completely safe, simulated world for practice. Think of VR as the ultimate training ground for maintenance in manufacturing, letting technicians master their skills with zero risk to themselves or your multi-million-dollar equipment.

In a VR simulation, a trainee can work on a perfect digital twin of a key asset. They can practice taking it apart and putting it back together, troubleshoot all kinds of simulated faults, and build the muscle memory they’ll need in an emergency. This hands-on, immersive learning sticks with people in a way that lectures and manuals just can’t.

The benefits of VR training aren’t fuzzy; they’re measurable:

- Accelerated Learning: Technicians can get up to speed on complex skills up to 75% faster.

- Zero Risk: Mistakes happen in the virtual world, not on your production line where they cost money and cause injuries.

- Improved Retention: People remember what they do. Immersive practice builds long-term knowledge.

By bringing AR and VR into your maintenance strategy, you aren’t just fixing today’s problems. You’re building a smarter, faster, and more capable workforce that’s ready for whatever comes next.

Your Roadmap to Implementing Modern Maintenance

Bringing new technology into your maintenance in manufacturing workflow can feel like a massive undertaking. But it doesn't have to be. Instead of trying to boil the ocean with a facility-wide overhaul, a smarter, phased approach is the key.

Think of it less like flipping a switch and more like building a bridge to a more efficient future, plank by plank. The trick is to start small, prove the concept, and then scale with confidence. This five-step path will help you break the process into manageable chunks, demonstrate value quickly, and bring your team along for the ride.

Step 1: Assess Your Current Operations

Before you can chart a new course, you have to know where you are right now. The first move is always a brutally honest assessment of your existing maintenance workflows. The goal here is simple: find your biggest and most expensive pain points.

Where are you losing the most time? Which machine breakdowns throw the biggest wrench into your production schedule? Are your senior experts constantly racking up travel miles for relatively minor fixes? Zeroing in on these critical areas helps you aim your initial efforts where they’ll have the biggest, most visible impact. This isn't about finding fault; it's about finding opportunity.

Step 2: Launch a Focused Pilot Project

Once you’ve identified your biggest headaches, resist the temptation to go big right away. Instead, launch a small, focused pilot project on a single, high-value asset. Pick a piece of equipment where unplanned downtime is especially painful or one that’s known for being a beast to repair.

Deploying a new solution, like an AR remote support tool, in this kind of controlled environment lets you work out the kinks and gather hard data without disrupting everything. A successful pilot on one of your most troublesome machines becomes a powerful internal case study.

A well-executed pilot is your single most persuasive tool. It shifts the conversation from hypothetical benefits to demonstrated, measurable ROI, making it much easier to get buy-in from stakeholders for a wider rollout.

Step 3: Choose the Right Technology Partner

Let's be clear: not all tech solutions are created equal. Your success hinges on finding a partner who truly gets the unique pressures and gritty realities of the industrial world. Look for a provider with a proven track record in manufacturing, not just a flashy software company.

You want someone who is willing to work with you to dial in the solution for your specific needs. A real partner does more than just sell you a license; they provide rock-solid support, share best practices from other deployments, and help you weave the new tools into your existing systems without causing chaos.

Step 4: Create a Solid Training Plan

Even the most brilliant technology is just an expensive paperweight if your team doesn't know how to use it. A comprehensive training plan isn't just a nice-to-have; it's non-negotiable. This means more than a single workshop and a user manual. It requires hands-on practice, ongoing support, and building real confidence.

When technicians see how new tools actually make their jobs easier, they’ll become your biggest champions. To help build out a curriculum that sticks, you can find great resources on developing effective maintenance technician training programs.

Step 5: Scale the Solution Intelligently

With a successful pilot in your back pocket and a team that’s trained and ready, it's time to scale. Take the lessons learned and the ROI data from your initial project and use them to guide a systematic rollout across other critical assets and departments.

This phased expansion allows you to manage costs, keep operations stable, and build on each success. It's how you methodically transform your entire maintenance organization, one proven step at a time.

Got Questions? We've Got Answers

You're not alone in wondering how all this new tech fits into the day-to-day reality of the factory floor. Let's tackle some of the most common questions we hear from teams looking to modernize their maintenance game.

How Exactly Does Predictive Maintenance Cut Costs?

It's all about stopping problems before they start. Unplanned downtime is a budget killer—it can easily cost a manufacturer over $100,000 per hour. Predictive maintenance uses data from sensors to see a failure coming, letting you schedule the repair on your own terms.

This means you’re not paying for emergency parts shipping or overtime for a last-minute fix. Even better, by catching small issues like an unusual vibration before they snowball into a total breakdown, you get more working years out of your expensive equipment. That’s a direct hit against premature capital spending.

What’s the Real Difference Between Predictive and Preventive Maintenance?

Think of it like this: Preventive maintenance runs on a calendar. You service a machine every three months, whether it needs it or not. It's a "just-in-case" strategy that can sometimes lead to unnecessary work and parts.

Predictive maintenance, on the other hand, runs on data. It’s a "just-in-time" approach, using real-time information from the machine to tell you exactly when it needs attention. You only step in when it's truly necessary, right before a problem is about to happen.

The big win with predictive is precision. You stop guessing and start listening to what your equipment is actually telling you. Every maintenance action is driven by data, adding direct value and cutting out wasted effort.

How Can AR and VR Actually Help My Technicians?

Augmented Reality (AR) and Virtual Reality (VR) aren't just buzzwords; they're incredibly practical tools that solve real, everyday maintenance headaches. They get the right information to your frontline crew, right when they need it, in a way that's easy to understand.

- AR for On-the-Spot Expert Help: A technician on the floor can put on a pair of smart glasses and show an expert—who could be hundreds of miles away—exactly what they're seeing. That expert can then guide them through a complex fix in real-time. A problem that might have taken days to solve is now handled in minutes.

- VR for Risk-Free Training: Imagine a new technician practicing a tricky repair on a perfect digital twin of your most complex machine. With VR, they can build muscle memory and confidence in a safe, simulated world without ever touching—or potentially damaging—the real thing.

Ready to see how immersive tech could look in your own operations? AIDAR Solutions builds the AR and VR tools that slash service times, eliminate expert travel costs, and give your technicians the support they need to get the job done right. Discover our solutions today.