Industrial Equipment Repairs: A Practical Guide

When a machine on the factory floor goes silent, it's never just about a broken part. Industrial equipment repair is the essential process of diagnosing the problem, servicing the machinery, and getting it back online. It’s far more than a line item for the maintenance department; it’s a critical function that dictates your productivity, keeps your team safe, and ultimately protects your bottom line.

A quiet production line is one of the most expensive sounds in manufacturing. The costs don’t stop at the repair invoice—they ripple out, touching every corner of the business.

The True Cost of Industrial Equipment Downtime

When a critical piece of equipment fails, the initial focus is on the direct costs: parts, labor, and the technician's time. But that’s just the tip of the iceberg. The real cost of unplanned downtime quietly erodes profit margins in ways that aren’t always immediately obvious.

The most immediate impact is stalled production. Every minute a machine sits idle is a minute of lost output, which translates directly to lost revenue. This halt in production can cause missed deadlines and difficulty in fulfilling orders, putting a serious dent in your operational reliability.

The Hidden Financial Drain

Beyond the obvious production losses, a host of indirect costs begin to accumulate. These hidden expenses often dwarf the initial repair bill and highlight the importance of efficient industrial equipment repairs.

Consider the labor impact. Your team is still on the clock, even when the line isn’t running, creating a direct labor cost for zero output. Once the machine is finally fixed, you're likely looking at overtime pay to catch up on the production backlog.

Logistics costs can also escalate. Expedited shipping may be required to get replacement parts faster, and rush delivery fees may be necessary to get finished products to customers on time, adding even more pressure to the budget.

When a machine fails, the costs multiply quickly. The immediate repair bill is just the beginning; the real damage comes from the chain reaction of operational and financial consequences.

The Ripple Effect of Unplanned Equipment Downtime

| Cost Category | Description | Example Financial Impact |

|---|---|---|

| Direct Repair Costs | The immediate, out-of-pocket expenses for parts, labor, and technician fees. | A $5,000 invoice for a new motor and a specialist technician. |

| Lost Production | Revenue lost for every unit that couldn't be produced while the machine was down. | $20,000 in lost sales for an 8-hour production stoppage. |

| Idle Labor | Wages paid to employees who are unable to work due to the equipment failure. | $4,800 in wages for a 12-person team during their shift. |

| Overtime Expenses | Additional labor costs required to catch up on the production backlog once repairs are complete. | $3,000 in overtime pay for a weekend catch-up shift. |

| Supply Chain Disruptions | Expedited shipping for parts, penalty clauses from customers for late delivery, and rush freight costs. | $1,500 in express air freight for a critical component. |

| Reputational Damage | Loss of customer trust and potential for future business if deadlines are consistently missed. | Losing a key contract worth $150,000 annually due to unreliability. |

This table shows how a single failure can trigger a cascade of expenses, turning a seemingly small issue into a significant financial event. It’s why smart repair strategies are so critical.

The financial stakes are astronomical. Industry benchmarks show that unplanned downtime can cost an average of $260,000 per hour in process manufacturing. A minor mechanical issue can quickly spiral into a full-blown financial crisis.

This intense pressure is why the industrial maintenance services market is growing. It's projected to jump from $58.04 billion in 2025 to a massive $76.96 billion by 2029. This growth is driven by companies adopting smarter, more predictive repair strategies powered by Industry 4.0 technologies.

Damage Beyond the Balance Sheet

The impact isn’t just financial. Repeated downtime erodes customer trust. If delays become a habit, clients may start looking for a more reliable supplier, potentially leading to a long-term loss of market share.

Ultimately, equipment repair should be treated as a core business strategy rather than a technical chore. Understanding the full cost of downtime is the best motivation to invest in proactive maintenance and modern repair solutions. For a deeper dive, our guide offers powerful strategies to reduce downtime in manufacturing.

Why Industrial Equipment Fails

To effectively manage industrial equipment repairs, it is crucial to understand why machines break down. A maintenance team must identify the root cause of a failure to prevent it from recurring.

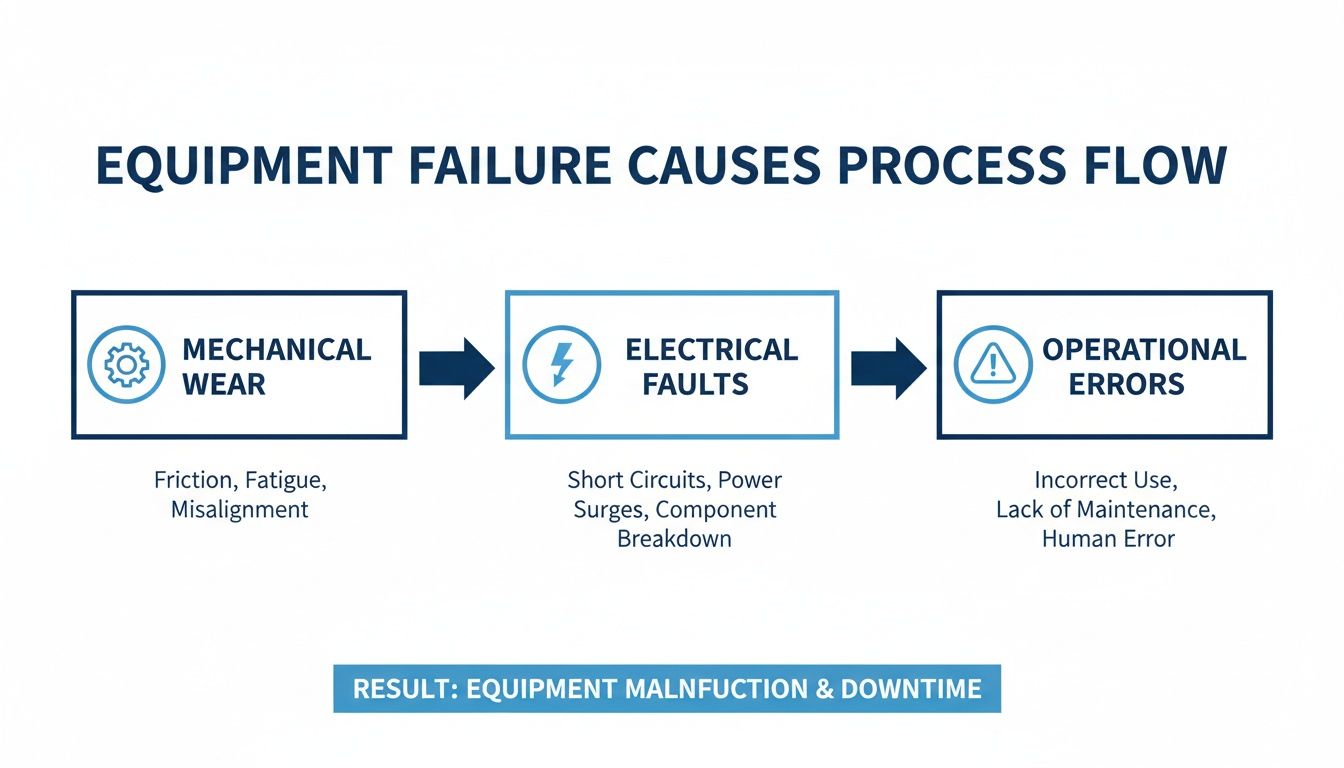

Most equipment failures can be attributed to one of three main categories: mechanical issues, electrical faults, or human error.

Consider a heavy-duty conveyor belt system. When it fails, it's often the result of a chain reaction. A bearing may have overheated and seized, a motor may have short-circuited, or an operator may have overloaded the belt. Each scenario points to a different root problem that requires a unique solution.

Ignoring the root cause means only treating a symptom. A seized bearing can be replaced, but if the underlying lubrication issue that caused it to overheat is not addressed, the same failure will likely occur again.

Mechanical Wear and Tear

The most frequent cause of failure is mechanical wear. Daily friction, vibration, and stress take a toll on a machine's physical parts. This slow, steady degradation is a natural part of a machine’s life cycle.

Think about the gears in a large industrial mixer. With every rotation, microscopic bits of metal wear away. This process, known as metal fatigue, eventually leads to tiny cracks or even broken teeth, bringing the entire operation to a halt.

Other common mechanical failures include:

- Bearing Failure: Constant friction and heat can cause bearings to seize, leading to catastrophic failure in rotating equipment like pumps and motors.

- Seal Degradation: O-rings and gaskets designed to prevent leaks can become brittle and crack over time, causing fluid or pressure to escape.

- Misalignment: When parts like shafts and couplings aren't perfectly aligned, it creates extra vibration and stress that accelerates wear on the entire system.

These problems usually develop slowly and often exhibit clear warning signs. Recognizing these signs is key to proactive maintenance. For a deeper dive, check out our article on condition monitoring and predictive maintenance.

Electrical System Faults

Modern industrial equipment is filled with complex electrical systems. From the main power feed to the smallest control circuit, a single electrical issue can shut down an entire production line. These problems are often less visible than mechanical damage but can be just as disruptive.

A sudden power surge, for example, can damage the sensitive electronics inside a CNC machine. The repair might involve replacing a costly control board, leading to significant downtime while waiting for the part to arrive.

A single electrical fault can cascade through a system, causing multiple component failures at once. What seems like a small wiring issue can quickly escalate into a major system-wide outage, making diagnosis and repair far more complex.

Common electrical culprits include:

- Overheating Components: Poor ventilation or excessive current can cause motors, transformers, and wires to overheat, leading to insulation failure and short circuits.

- Loose Connections: Constant vibration can loosen electrical connections, creating intermittent faults that are difficult to diagnose.

- Control System Malfunctions: Glitches in programmable logic controllers (PLCs) or sensors can cause machines to operate erratically or shut down completely.

Operational and Human Errors

The final category of failure is related to how equipment is used. Even the most robust machinery can fail if operated incorrectly or maintained poorly. These errors are often the most preventable.

Consider a hydraulic press in a metal stamping plant. If an operator consistently pushes it past its maximum pressure rating to increase speed, they are putting excessive strain on its cylinders and seals. This improper use will inevitably lead to premature and costly failure.

Preventing these issues comes down to clear procedures and thorough training.

- Improper Operation: Running equipment too fast, too slow, or with incorrect materials.

- Inadequate Maintenance: Skipping routine lubrication, filter changes, or calibration checks.

- Lack of Training: Operators who do not fully understand a machine’s limits are more likely to make mistakes that cause damage.

By understanding these three core failure modes—mechanical, electrical, and operational—teams can move beyond simply fixing what’s broken. They can build a proactive culture focused on root cause analysis to prevent future failures before they stop the production line.

Building a Proactive Repair Workflow

Waiting for equipment to break down is an outdated and expensive strategy. A modern approach to industrial equipment repairs reverses this model. Instead of reacting to failures, you build an intelligent, proactive workflow that identifies problems before they shut down your production line.

This shift transforms chaotic emergencies into scheduled, orderly maintenance events. It's a structured cycle designed to reduce disruption and maximize the operational life of your equipment. The goal is to detect issues early, diagnose them correctly the first time, execute the fix efficiently, and learn from every event to prevent recurrence.

The Four Stages of an Intelligent Repair Cycle

A truly proactive workflow is not a single action but a four-stage loop. Each phase feeds into the next, creating a system that solves current problems and makes the entire operation smarter and more resilient over time.

- Early Detection: This is your first line of defense. By placing Internet of Things (IoT) sensors on critical machines, you can monitor vital signs like vibration, temperature, and pressure in real-time. This acts as an early warning system, catching subtle signs of a developing fault long before it becomes critical.

- Accurate Diagnosis: Once an alert is received, the goal is to determine the exact problem. Data analytics platforms can process sensor data to pinpoint the likely cause. This initial diagnosis can then be enhanced with remote expert assistance, allowing a senior engineer to guide an on-site technician from anywhere, confirming the issue without costly travel.

- Swift Repair Execution: With a clear diagnosis, the repair becomes a smoother, faster process. Technicians equipped with digital work instructions on a tablet or AR headset can follow a step-by-step guide, ensuring the repair is done correctly and reducing the risk of human error on complex jobs.

- Verification and Data Capture: After the repair is complete, the final step is to verify its success and close the information loop. This involves running tests and logging all event details, from the initial alert to the specific parts used. This data is then fed back into a central system, providing valuable insights for future predictive maintenance efforts.

This infographic breaks down some of the most common failure points that a proactive workflow helps you get ahead of.

By monitoring these common issues, maintenance teams can direct their predictive tools where they will have the greatest impact.

The global market for industrial machinery repair is massive—valued at $34.1 billion in 2024 and projected to hit $60.27 billion by 2035. This growth is fueled by technology. Companies adopting predictive tools powered by AI and IoT are seeing repair times reduced by 30-50%. Sustainability is also a major driver, as new regulations encourage refurbishing parts, which can cut waste by 40%.

Key Metrics That Drive Improvement

To manage a repair workflow effectively, you must be able to measure it. Two of the most important key performance indicators (KPIs) in maintenance are Mean Time To Repair (MTTR) and Overall Equipment Effectiveness (OEE).

Mean Time To Repair (MTTR) is the average time it takes to repair a machine after it fails, from the moment it goes down until it’s operational again.

A low MTTR is a direct reflection of an efficient repair process. It indicates that your team can diagnose issues quickly, access the right parts and tools, and execute the fix without unnecessary delays.

Overall Equipment Effectiveness (OEE) provides a comprehensive view of production health. It is a score calculated by multiplying three factors:

- Availability: How much of the scheduled production time is the machine actually running?

- Performance: How fast is the machine running compared to its maximum potential speed?

- Quality: How many of the parts produced are good, defect-free units?

Building a solid repair workflow is ultimately about mastering industrial equipment repair efficiently. An OEE score of 100% represents perfection, while 85% is considered world-class. Tracking OEE shows you exactly how equipment failures, slowdowns, and defects are impacting your bottom line. By focusing on these metrics, you can transform your repair workflow from a cost center into a powerful engine for continuous improvement.

To dig deeper into this approach, check out our full guide on preventive and predictive maintenance strategies.

Adopting Technology for Smarter Maintenance

A proactive workflow is powerful, but the right tools are needed to unlock its full potential. Moving beyond paper manuals and constant phone calls, forward-thinking maintenance teams are embracing technologies like Augmented Reality (AR) and Virtual Reality (VR) to solve their toughest challenges. These are practical tools delivering real results today.

Imagine a technician on the floor facing a complex hydraulic pump. Instead of searching through a binder, they put on an AR headset. Digital instructions are instantly overlaid onto their view of the machine. Interactive 3D schematics and live sensor readings appear in their line of sight, guiding them through the entire repair.

This represents a fundamental shift in how industrial equipment repairs are performed, moving from reliance on memory and guesswork to precise, digitally guided work.

Augmented Reality: The On-Site Digital Expert

Augmented Reality acts as a digital co-pilot for on-site technicians, bridging the gap between the physical machine and the technical data needed to repair it. By providing real-time, context-aware information, AR addresses some of the biggest challenges in maintenance.

The most immediate benefit is a significant reduction in human error. When a technician sees a digital arrow pointing to the exact bolt to be tightened or watches a brief animation of a disassembly sequence, the likelihood of a mistake decreases dramatically. This leads to higher first-time fix rates, fewer repeat visits, and less downtime for critical assets.

AR empowers technicians to solve problems faster and more accurately by putting the right information in their field of view at the exact moment they need it. This simple shift drastically reduces diagnostic time and accelerates the entire repair cycle.

This is a game-changer when a junior technician encounters an unfamiliar problem. Through their AR device, they can share their exact point of view with a senior expert who may be hundreds of miles away. The expert sees what the technician sees and can provide annotations and instructions directly on their screen. This is like having your best expert at the job site without the associated travel costs and delays.

Virtual Reality: The Ultimate Training Ground

While AR excels in the field, Virtual Reality is the champion of the training room. VR creates a fully immersive, computer-generated world where technicians can practice complex and high-stakes repairs in a completely risk-free environment. It is like a flight simulator for your most expensive and dangerous machinery.

Trainees can disassemble a virtual engine, troubleshoot a simulated electrical fault, or practice lockout/tagout procedures without any danger to themselves or the actual equipment. This hands-on experience builds muscle memory and confidence in a way that traditional training methods cannot.

VR training delivers solid business outcomes:

- Accelerated Learning: New hires get up to speed much faster with immersive, interactive training.

- Reduced Risk: Teams can master hazardous procedures without real-world consequences.

- Zero Material Waste: Trainees can make mistakes and try again without consuming expensive parts or supplies.

By integrating these tools, companies can not only improve their repair processes but also build a smarter, more efficient, and more resilient workforce. As industrial systems become more complex, so do the tools needed to maintain them. Companies are increasingly exploring advanced technologies, such as artificial intelligence solutions for industrial and electrical networks, to stay ahead. This move toward smarter technology is shaping the future of industrial maintenance.

Getting Started with AR and VR Solutions

Understanding the potential of Augmented and Virtual Reality is one thing; integrating these tools into daily operations is another. The key is a structured, phased approach that ensures these technologies deliver real value for your industrial equipment repairs, rather than becoming another underutilized gadget.

The journey begins not with the technology, but with your people and processes. Start by identifying the most persistent pain points in your maintenance workflow. Do your technicians frequently need remote support for complex machinery? Is training new hires on dangerous equipment a slow and stressful process? These high-friction, high-cost problems are prime candidates for an AR/VR solution.

Begin with a Targeted Pilot Program

Avoid attempting a massive, facility-wide rollout from the start. Successful adoptions begin small. A focused pilot program allows you to demonstrate tangible value, resolve issues in a controlled environment, and build momentum within your organization. This approach minimizes risk while creating a clear blueprint for future expansion.

Your pilot should focus on a single, high-impact use case. For example, you could equip a small team of field technicians with AR headsets to tackle one specific, notoriously difficult repair. The goal is to create a powerful success story that shows undeniable improvements in key metrics.

A well-executed pilot program does more than just test the technology; it builds internal champions. When managers and technicians see firsthand how a tool makes their jobs easier, safer, and more effective, they become its most persuasive advocates.

With a compelling case study, you can move toward a broader rollout with confidence and strong internal support.

Scaling and Measuring Your Return on Investment

Following a successful pilot, scaling the solution involves strategic expansion. The focus shifts to making it a seamless part of existing workflows, providing robust training, and ensuring consistent adoption across all teams. Effective change management is critical at this stage to overcome resistance and drive home the benefits for everyone involved.

The final and most crucial phase is measuring your return on investment. This involves tracking specific operational improvements that have a direct impact on your bottom line.

Key metrics to watch include:

- Mean Time To Repair (MTTR): How much has the average time to complete a repair decreased?

- First-Time Fix Rate: Are more repairs being completed correctly on the first attempt?

- Travel Cost Reduction: How much are you saving by eliminating the need to fly experts to remote sites?

- Training Efficiency: Are new technicians becoming proficient faster and with fewer resources?

The results can be significant. Companies using immersive AR/VR platforms have reported substantial reductions in repair times and unplanned downtime. Platforms like AIDAR.SERVICE deliver real-time AR support that can slash expert travel by 75% and cut service times in half. Meanwhile, training tools like AIDAR.SKILLS have been shown to accelerate learning by an incredible 75%.

By methodically implementing these tools and tracking their impact, you can transform maintenance operations from a cost center into a true competitive advantage. You can find even more insights in our guide to using augmented reality for maintenance.

Common Questions About Modern Industrial Repairs

As companies consider updating their repair and maintenance operations, many questions arise. Shifting from a reactive "fix it when it breaks" model to a proactive, tech-driven strategy is a significant change. Here are some of the most common inquiries.

What’s the First Step to Adopting Predictive Maintenance?

Getting started is more about strategy than technology acquisition. The best first step is to identify your most critical assets—the machines that are essential to your operations.

Next, determine their most common failure modes. This is where you should install your first IoT sensors to begin collecting performance data like temperature, vibration, and pressure. This targeted data forms the foundation for building useful predictive models.

How Does AR Actually Help a Technician in the Field?

Augmented Reality (AR) functions as an intelligent assistant that sees what your technician sees. Through a headset or tablet, AR overlays digital information directly onto their view of the physical equipment. They might see step-by-step instructions floating next to the part they're working on, 3D diagrams of internal components, or receive real-time video guidance from a senior expert who is miles away.

This technology acts as a digital guide, placing critical information directly in the technician's line of sight. It eliminates the need to stop and consult a paper manual, which reduces guesswork and makes the repair faster and more accurate.

This hands-on, in-context guidance is invaluable for complex or unfamiliar tasks. It helps ensure that all team members, regardless of experience, perform repairs correctly and to the same high standard.

Is It Hard to Get an Existing Team on Board with AR and VR?

Modern AR/VR platforms are designed to be intuitive, so the learning curve is not as steep as many assume. The key to a successful rollout is to start small with a targeted pilot program. Choose a specific problem, demonstrate the technology's value in solving it, and gather direct feedback from the users.

This phased approach, combined with proper training, helps the team become comfortable with the technology and see its real-world benefits firsthand. Once they recognize that it makes their job easier, adoption tends to follow naturally. The need for these efficient repair solutions is growing. The construction equipment repair market alone hit $34.6 billion in 2024, with repairs projected to climb past $21.9 billion by 2034 as heavy machinery ages. You can explore these trends by checking out the full research on industrial machinery repair.

Ready to see what this looks like for your own maintenance and training workflows? AIDAR Solutions builds immersive AR and VR tools that deliver real results, from slashing downtime to getting new hires up to speed faster. Find out how we can help you build a more efficient, resilient operation at https://aidarsolutions.com.