What Is XR Technology? A Guide to AR, VR, and MR

Extended Reality (XR) is a powerful set of technologies that merge our physical world with digital information. It is the umbrella term that covers everything from adding a simple digital layer to your vision to stepping into a completely new, virtual world.

At its core, XR is fundamentally changing how businesses operate—how teams interact with complex machinery, learn new skills, and collaborate with colleagues from across the globe.

Defining the XR Spectrum

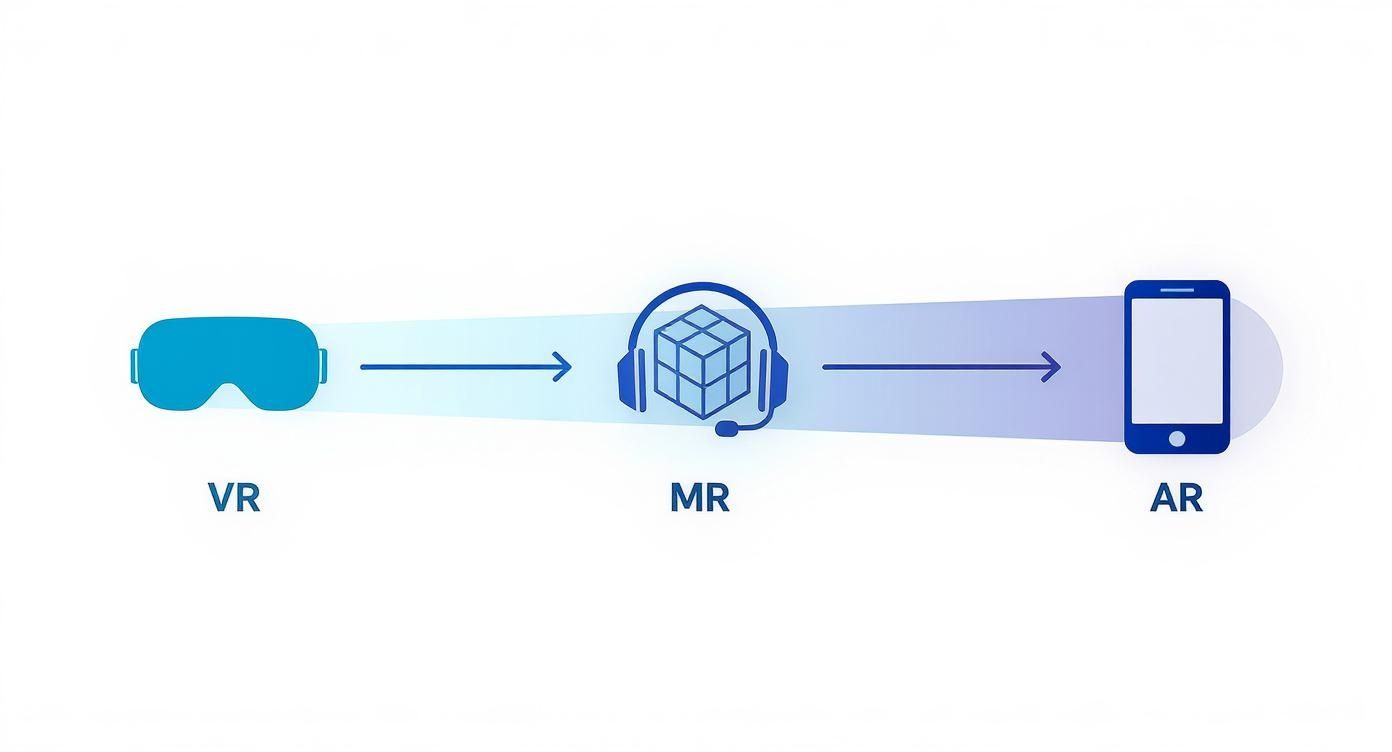

Imagine a sliding scale. On the far left, you have the physical world as you see it now. On the far right, you have a totally computer-generated reality. XR is everything on that scale, from the slightest digital enhancement to full-blown virtual immersion.

This spectrum is built on three core technologies. Each one offers a unique way to blend physical and digital content, creating significant opportunities for industries to elevate training, streamline operations, and boost collaboration. The main difference between them is the level of immersion.

The Three Pillars of XR

Understanding these three components is the key to unlocking what XR can do for a business. They are not competing technologies; they are different tools for different jobs.

Here is a breakdown of the three core pillars:

- Virtual Reality (VR): This technology provides full immersion. When you put on a VR headset, you are transported to an entirely different, digitally created world. It completely replaces your real-world surroundings, making it ideal for high-stakes training simulations where users can practice in a risk-free environment.

- Augmented Reality (AR): Instead of replacing your world, AR adds to it. It overlays digital information—like text, images, or animations—onto your view of the real world. In an industrial setting, this allows a technician to see step-by-step repair instructions directly on a piece of equipment through smart glasses.

- Mixed Reality (MR): This is the most advanced form of XR, anchoring interactive digital objects into your physical space. It's not just a flat overlay; you can place a virtual 3D model of a machine part on a real table and walk around it as if it were actually there.

This diagram illustrates how these technologies fit together on the reality-virtuality continuum.

The journey from AR to VR is defined by the degree to which digital information is blended with our physical environment.

To make this even clearer, here’s a quick comparison of the core components.

The XR Spectrum at a Glance

| Technology | Definition | Immersion Level | Device Example |

|---|---|---|---|

| Augmented Reality (AR) | Overlays digital info onto the real world. | Low – enhances reality, doesn't replace it. | Smartphones, smart glasses |

| Mixed Reality (MR) | Anchors interactive digital objects into the real world. | Medium – digital and physical objects co-exist. | Advanced headsets like Microsoft HoloLens |

| Virtual Reality (VR) | Replaces the real world with a fully digital environment. | High – complete sensory immersion. | Headsets like Meta Quest or HTC VIVE |

Each point on this spectrum opens up new possibilities for solving real-world business challenges.

This foundational knowledge helps clarify how each technology solves specific operational challenges. If you're interested in digging deeper, you can learn more about what is extended reality and its direct applications in business, setting the stage for more advanced strategies.

Breaking Down the Core Components: AR, VR, and MR

To fully grasp XR, it is essential to look at its three core pillars: Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR). Each one is a distinct point on the "immersion spectrum," offering unique capabilities to solve different business problems.

Think of them as specialized tools in a single, powerful toolbox.

The global XR market is largely driven by AR and VR technologies. While VR currently holds a significant share, AR is growing rapidly, especially in industrial settings. Research indicates that the AR segment will eventually capture the largest market share due to its vast potential in enterprise, education, and interactive product support.

Augmented Reality (AR): Adding a Digital Layer to Your World

Augmented Reality enhances the real world; it does not replace it. AR technology overlays digital information—like text, 3D models, or step-by-step instructions—directly onto your physical environment, typically viewed through a smartphone, tablet, or specialized smart glasses.

For example, a field technician repairing a complex piece of machinery can use an AR headset to see digital arrows, text guides, and schematics projected directly onto the equipment. This immediate, in-context information reduces errors, accelerates repairs, and makes bulky paper manuals obsolete.

AR is fundamentally about providing the right information, at the right time, in the right place. It connects the digital and physical workflows of your frontline teams, creating a more intuitive and efficient operational environment.

One of the key benefits of AR is its accessibility, as it often works on devices employees already carry. It is also important to consider how to build these experiences inclusively, for instance, by creating inclusive immersive experiences with VR and AR from the start.

Virtual Reality (VR): Full Immersion for Training and Simulation

Virtual Reality sits on the opposite end of the spectrum. Instead of adding to your world, VR completely replaces it with a computer-generated one. By wearing a headset that blocks out all external sight and sound, users are immersed in a simulated reality where they can interact with digital objects and scenarios.

The primary strength of VR lies in its ability to create realistic, risk-free training environments.

- Safety Training: Employees can practice responding to hazardous situations, like a chemical spill or equipment failure, without any real-world danger.

- Complex Skills Development: A surgeon can rehearse a difficult procedure, or a new hire can learn to operate heavy machinery in a controlled, repeatable simulation.

- Design Prototyping: Engineers can walk through a full-scale digital model of a new factory or product, identifying design flaws long before a physical prototype is built.

This deep level of immersion builds strong muscle memory and boosts information retention, making training far more effective and efficient than traditional methods.

Mixed Reality (MR): Blending Digital and Physical Worlds

Mixed Reality is the most advanced form of XR, representing a true merger of the real and virtual. Unlike AR’s simple overlays, MR anchors digital objects to the physical environment, making them appear as if they're actually there. Crucially, it lets you interact with them in real time.

For example, an architect wearing an MR headset could place a 3D model of a new building on a boardroom table. The team could then walk around it, view the model from any angle, and even manipulate parts of the structure to make changes on the fly. The digital object understands and interacts with the physical space around it.

For a more detailed comparison, our guide on mixed reality vs augmented reality offers a deeper dive into what makes each one unique.

How Industries Are Using XR to Transform Operations

The theory behind XR is interesting, but its real power becomes clear in its practical applications. Across the industrial world, companies are using these immersive tools to solve tangible and costly operational problems. This technology is no longer a futuristic concept; it is a practical solution for making work safer, more efficient, and easier to learn.

The rapid adoption of XR across different sectors highlights its value, with enterprise and industrial applications becoming a major growth driver. In manufacturing, teams use XR for virtual prototyping and remote maintenance. In healthcare, it's used for planning complex surgeries and training medical professionals. This widespread use demonstrates how adaptable and valuable these tools have become.

Let’s examine three high-impact scenarios where XR is making a measurable difference right now.

Zero-Risk Training Through Virtual Reality Simulations

Consider a new technician learning to operate a complex, multi-million dollar piece of machinery. Traditional on-the-job training is slow, expensive, and carries the risk of human error, which could damage equipment or cause injury.

Virtual Reality changes this paradigm.

With a VR headset, that same trainee can step into a photorealistic, fully interactive digital twin of their work environment. They can run through standard operating procedures, troubleshoot simulated equipment failures, and practice emergency protocols—all within a 100% safe and controlled setting.

This approach provides significant advantages:

- Accelerated Learning: Immersive training builds muscle memory and improves knowledge retention far more effectively than reading a manual or watching a video.

- Reduced Error Rates: Trainees can make mistakes, learn from them, and try again without any real-world consequences. This builds competence and confidence before they handle real equipment.

- Cost Savings: Businesses no longer need to take valuable machinery offline for training and can avoid costs associated with material waste or accidental damage.

Real-Time Guidance with AR-Powered Remote Support

Imagine a field technician at a remote site facing an unexpected equipment failure. Traditionally, this situation would lead to costly downtime while waiting for a senior expert to travel to the location, a process that could take days.

Augmented Reality offers an immediate solution. By wearing a pair of AR smart glasses, the on-site technician can stream their exact point-of-view to an expert located anywhere in the world. The expert sees what the technician sees and can provide real-time guidance by overlaying digital instructions, diagrams, or notes directly onto the technician's view of the equipment.

This "see-what-I-see" capability effectively teleports your most skilled experts to any job site instantly. It slashes travel costs, drastically reduces equipment downtime, and ensures complex problems are solved correctly the first time.

This powerful application of augmented reality for industry not only speeds up repairs but also serves as an on-the-job training tool, upskilling frontline workers with every service call.

Streamlining Maintenance with Interactive 3D Instructions

Finally, picture an engineer performing routine maintenance while juggling a dense paper manual or a laptop, constantly looking back and forth between the instructions and the task. This workflow is slow, inefficient, and prone to mistakes.

XR, especially AR and MR, transforms this process. An engineer wearing a headset can see interactive, step-by-step 3D instructions overlaid precisely onto the machine they are servicing.

- Digital arrows can point to the exact bolt that needs to be tightened.

- Short, animated sequences can show the correct way to remove and replace a specific component.

- Critical data, like temperature or pressure readings from sensors, can be displayed directly in their line of sight.

This turns complicated procedures into simple, intuitive, guided workflows. It reduces the cognitive load on the technician, minimizes the chance of errors, and helps ensure maintenance is completed faster and more accurately—improving equipment reliability and operational uptime.

Measuring the Business Impact and ROI of XR

Adopting any new technology requires a solid business case, and XR is no exception. While immersive experiences are impressive, the real conversation for any business revolves around a measurable Return on Investment (ROI).

The impact of XR translates directly into quantifiable gains in efficiency, safety, and cost savings. The technology is a key driver in a rapidly expanding global market projected to exceed USD 250 billion by 2025, fueled by tangible business results across sectors from industrial training to healthcare.

However, the true ROI for a business comes from solving specific, costly operational bottlenecks. By tracking the right Key Performance Indicators (KPIs), you can build a powerful business case that demonstrates clear value.

Boosting Operational Efficiency

One of the most immediate benefits of XR is a dramatic increase in workforce efficiency. When a technician can access a schematic hands-free in their line of sight, or a trainee can practice a complex repair in a virtual environment, work gets done faster and with fewer mistakes.

For example, using AR for remote assistance in a field service operation can slash problem resolution time. Instead of flying a senior expert to a remote site, a junior technician can receive real-time, over-the-shoulder guidance. This has been shown to cut service times in half.

The core value of XR is its unique ability to close the gap between digital information and physical action. This direct link eliminates guesswork, reduces mental strain, and empowers employees to perform at a much higher level.

This efficiency boost also applies to manufacturing, where VR training can significantly reduce the time it takes for a new hire to become fully productive. Studies have shown that immersive learning can improve employee performance by up to 70%.

Driving Direct Cost Savings

Beyond efficiency gains, XR delivers concrete cost savings. These savings are realized in several key areas, building a compelling financial argument for adoption.

Here’s where you’ll see the biggest impact on your bottom line:

- Reduced Travel Expenses: AR-powered remote support makes your best experts virtually present anywhere in the world. This drastically cuts down on flights, hotels, and per diems, with some companies reporting reductions in expert travel by as much as 75%.

- Lower Training Costs: Virtual training eliminates wasted raw materials, the need for dedicated training machinery, and the risk of damaging expensive live equipment. It also allows for training more people simultaneously, increasing throughput without additional overhead.

- Minimized Equipment Downtime: Faster repairs and more accurate maintenance lead to increased uptime. Every hour of avoided downtime contributes directly to the business's bottom line and ROI.

To estimate the potential financial impact for your organization, a dedicated tool can be useful. For instance, our training ROI calculator helps model the potential savings of implementing an immersive learning program.

Enhancing Workplace Safety

Improving safety is a critical priority for any industrial operation, and its ROI is measured in both financial terms and human well-being. XR provides an effective platform for creating a safer workplace by allowing employees to practice high-stakes procedures in a zero-risk environment.

This proactive approach to safety training yields significant benefits. By enabling workers to experience and respond to simulated emergencies, you build the muscle memory needed to react correctly during a real incident, resulting in a significant reduction in workplace accidents and injuries.

Fewer accidents mean lower insurance premiums, less lost time, and a stronger safety culture that attracts and retains top talent. While the well-being of employees is invaluable, the financial impact of a safer workplace is a core component of any XR business case.

Key Metrics for Measuring XR Program Success

To demonstrate the value of your XR investment, it is essential to track the right data. Focusing on a handful of clear, high-impact KPIs will help you prove success and justify further expansion.

| Impact Area | Key Performance Indicator (KPI) | Example Measurement |

|---|---|---|

| Operational Efficiency | Task Completion Time | Reduction in average repair time by 35% for AR-guided maintenance. |

| First-Time Fix Rate | Increase in first-time fix rates from 70% to 92% for junior technicians. | |

| Cost Savings | Travel Expenditure | $250,000 saved in annual travel costs by using remote expert support. |

| Training Material Costs | 80% reduction in scrap material and consumable costs in new hire training. | |

| Safety & Compliance | Number of Safety Incidents | 50% decrease in OSHA-recordable incidents in the first year of VR training. |

| Error Rate in Procedures | Reduction in critical errors during complex assembly from 15% to 2%. | |

| Employee Performance | Time to Competency | New hires reach full productivity 40% faster than with traditional methods. |

| Knowledge Retention | 90% knowledge retention rate one month after VR training vs. 55% for classroom. |

By tracking metrics like these, your XR program transitions from an innovation project to a proven strategic asset that directly contributes to the bottom line.

Your Enterprise XR Deployment Checklist

Transitioning from understanding XR to implementing it can seem like a significant undertaking. However, with a structured plan, you can navigate the process effectively. This checklist serves as a roadmap to guide you through the critical steps of a successful XR deployment, from initial concept to full-scale integration.

This framework is designed for strategic thinking, helping you avoid common pitfalls and build a solid foundation for an XR program that delivers real value and can scale over time.

Define a Strategic Pilot Project

Before considering a company-wide rollout, it is best to start small and focused. A pilot project is the most effective way to prove value, gain stakeholder buy-in, and resolve any issues without a large-scale commitment. The goal is simple: solve one, high-impact business problem.

Identify a specific pain point where XR can make a tangible difference. This could be reducing errors in a complex assembly process, accelerating the onboarding of new technicians, or cutting travel costs for senior experts.

Focus on a use case with a clear, measurable outcome. A pilot that demonstrates a tangible ROI—like a 30% reduction in training time or a 50% decrease in equipment downtime—becomes a powerful tool for securing broader support.

Once you have your target, define the scope of the project, including who is involved and what success looks like in quantifiable terms. A tight focus will help you achieve a quick, demonstrable win.

Select the Right Hardware for the Job

XR hardware is not one-size-fits-all; the device you choose must match the job and the environment. While it is easy to be impressed by the latest specifications, the focus should remain on what the user needs to accomplish.

Consider the following when evaluating hardware:

- What’s the task? A VR headset is ideal for fully immersive safety training. However, for a field technician who needs hands-free access to schematics, AR smart glasses are the more practical choice. For simple information overlays, existing smartphones or tablets may suffice.

- Where will it be used? An office environment is very different from a factory floor or a remote outdoor site. Factors like durability, battery life, and connectivity are critical in industrial settings.

- Is it comfortable? If a device is meant to be worn for extended periods, it must be lightweight and well-balanced. An uncomfortable headset will likely go unused, regardless of its technological capabilities.

The right device should feel like a natural part of the workflow, not an awkward gadget.

Evaluate SaaS vs. On-Premise Deployment

The next decision is how to deploy the software. This choice impacts everything from initial cost and scalability to data security and IT resource allocation. The two main paths are Software-as-a-Service (SaaS) and on-premise.

A SaaS model is a cloud-based solution, typically paid for via subscription. This approach significantly reduces upfront costs, simplifies updates, and allows for rapid scalability. It is an excellent choice for organizations that want to deploy quickly without a large IT commitment.

An on-premise deployment, in contrast, means the software is hosted on your own servers. This provides complete control over data and security, which is often a critical requirement for industries with strict compliance or data privacy regulations. This option requires a larger upfront investment and dedicated IT resources for maintenance.

Plan for System Integration and Change Management

Even the best XR solution is ineffective if it doesn’t integrate with your existing systems or if your team is resistant to using it. A successful launch requires a solid plan for both the technology and the people.

Technical Integration:

Your XR platform should not operate in isolation. Map out how it will connect to existing systems, such as your Learning Management System (LMS) for training data or your Enterprise Resource Planning (ERP) for work orders. Seamless data flow makes the tool more powerful and integrates it into existing workflows.

Change Management:

Ultimately, technology adoption is about people. A clear change management plan is essential to address potential resistance and ensure everyone understands the purpose and benefits of the new tool.

- Communicate early and often: Explain the benefits from the user’s perspective. How will this make their job easier, safer, or more effective?

- Involve end-users: Include key team members in the pilot and testing phases. Their feedback is invaluable, and their participation can turn them into advocates.

- Provide thorough training: Organize hands-on sessions to help users become comfortable with the new hardware and software. Confidence is key to adoption.

By addressing both the technical and human elements, you pave the way for XR to become a natural and valuable part of your daily operations.

Answering Your Key Questions About XR Technology

As you explore what XR technology is and how it might fit into your business, several practical questions often arise. Understanding the definitions is one thing; seeing a clear path to real-world application is another. Let’s address these common questions with straightforward, practical answers.

How Does XR Differ from the Metaverse?

It is common to confuse XR and the metaverse, but they serve different functions. The simplest distinction is that XR is the technology available today (the 'how'), while the metaverse is a vision for a future, shared virtual world (the 'where').

XR technologies, such as VR headsets and AR-enabled tablets, are the tools we use to enter and interact with 3D digital environments. They comprise the hardware and software platforms that enable these experiences. The metaverse, in contrast, is a conceptual, interconnected network of virtual worlds that is still largely theoretical. XR is the bridge that may one day lead to the metaverse.

Think of it this way: XR technology is the car, engine, and steering wheel you can purchase and use today. The metaverse is the futuristic, continent-spanning superhighway system on which those cars might eventually travel.

For now, the focus for businesses should be on the practical tools of XR. This is the collection of hardware and software you can deploy today to solve immediate business problems and achieve a tangible return.

What Are the Biggest Hurdles to Enterprise XR Adoption?

While the benefits of XR are compelling, implementing a program involves navigating a few common challenges. The key is to view them not as roadblocks, but as solvable problems that require careful planning.

Here are the main hurdles businesses often encounter:

- Initial Hardware Investment: The cost of specialized headsets and powerful PCs can be a concern. This is why starting with a use case that delivers a fast, measurable ROI is crucial.

- IT Infrastructure Demands: High-quality XR, particularly VR, can require significant network bandwidth and processing power. Existing infrastructure may need to be upgraded to ensure smooth performance.

- Custom Content Creation: Developing custom training simulations or maintenance guides can be challenging without the right in-house skills or an external partner.

- Managing User Adoption: This is a critical factor. A strong change management plan is necessary to ensure your team is comfortable and confident using the new technology.

Strategically addressing these challenges is key. By focusing on an intuitive user experience and initiating a well-defined pilot project, you can manage these issues and build momentum for a wider rollout.

How Can We Start with XR Without a Massive Upfront Investment?

Embarking on an XR initiative does not have to involve a large capital outlay. There are several smart, scalable ways to get started, prove the value, and build a business case without a significant initial investment. The goal is to start small, achieve a clear win, and expand from there.

A low-investment entry point is entirely feasible. The most effective approach is to launch a targeted pilot program focused on solving a single, high-impact problem, such as a process with a high error rate or a particularly complex training module. Proving value on a small scale makes it much easier to secure a budget for a larger program.

Additionally, consider the hardware you already have. Many powerful AR applications work on the smartphones and tablets your team already uses, allowing you to introduce digital work instructions and guided workflows with zero new hardware cost.

Another excellent strategy is to partner with a full-service XR provider that offers a scalable Software-as-a-Service (SaaS) solution. This model converts a large capital expense into a predictable, manageable subscription and provides expert guidance to ensure a successful launch and integration.

Ready to explore how XR can solve your specific operational challenges without a massive upfront investment? At AIDAR Solutions, we specialize in crafting scalable AR and VR solutions that deliver measurable ROI. Discover our tailored enterprise applications and start your XR journey with a trusted partner.