Improving Productivity in Manufacturing with AR/VR

Boosting productivity on a manufacturing line is no longer about minor process tweaks. The most significant challenges now lie in accelerating new hire training and managing increasingly complex assemblies without an increase in errors.

This is where technologies like Augmented and Virtual Reality (AR/VR) provide practical solutions. Far from being conceptual, these are proven tools actively solving these core problems, revolutionizing training, maintenance, and quality control.

The Next Leap in Manufacturing Productivity

Every manufacturing leader is pursuing a competitive edge. While supply chain and assembly line optimization remain vital, the greatest opportunities now come from empowering your workforce on the factory floor.

The primary struggle has shifted to managing intricate product designs, reducing the learning curve for new employees, and ensuring first-time quality. Immersive technologies offer a clear path forward, providing tangible solutions to these persistent production hurdles.

Redefining What's Possible on the Floor

At its core, improving manufacturing productivity is about enabling people to perform their best work safely and efficiently. AR/VR achieves this by fundamentally changing how workers access and use information directly at their point of work. For any business serious about innovation, exploring essential digital transformation strategies is a critical step.

Here’s how these solutions deliver practical benefits:

- Reduced Cognitive Load: With AR, digital instructions are overlaid directly onto physical equipment. A technician no longer needs to shift focus between a paper manual or a tablet and the task at hand. All necessary information is integrated into a single field of view.

- Accelerated, Safe Training: VR creates ultra-realistic, zero-risk training simulations. New hires can master complex machinery or practice hazardous procedures without ever setting foot on the actual production floor, eliminating risks to both personnel and equipment.

- Informed, Faster Decisions: A technician can receive real-time data visualizations or a remote expert’s guidance directly in their field of view. This enables problem resolution in minutes instead of hours, significantly reducing costly downtime.

The Supporting Data

The adoption of new technology ultimately hinges on ROI. The data clearly shows that technology-driven efficiency has a direct, positive impact on the bottom line.

Recent statistics from the U.S. Bureau of Labor Statistics illustrate this point. In one quarter, U.S. manufacturing productivity increased by 2.5%, driven by a 3.5% rise in output while hours worked only grew by 0.3%. This demonstrates how strategic technology adoption allows for greater production without a proportional increase in labor hours.

By bridging the gap between digital information and the physical world, AR and VR offer more than just an incremental bump. They represent a fundamental shift in how work gets done, directly improving output, quality, and your team's capabilities.

This guide moves beyond theory to provide practical insights. We will explore how you can integrate these powerful tools into your existing workflows, using real-world scenarios and actionable steps to make a significant impact. If you're interested in other emerging technologies, we have a detailed piece on new technologies in manufacturing.

How AR Untangles Complex Assembly Tasks

Imagine an assembly line where technicians are not constantly referencing dense paper manuals. Instead, they see digital instructions, holographic guides, and precise tool placements overlaid directly onto their workspace. This is how Augmented Reality (AR) is boosting productivity on factory floors today.

By projecting interactive, step-by-step guidance into an employee’s line of sight, AR eliminates the ambiguity that often leads to errors and slowdowns in complex tasks. This is particularly valuable for high-stakes assemblies, such as aerospace components, where a single misplaced bolt can have significant consequences.

Taking the Guesswork Out of the Equation

The primary benefit of AR in assembly is the reduction of cognitive load—the mental effort required to interpret instructions and translate them into physical actions. When a technician must constantly switch focus between a manual, a screen, and their hands, mental energy is consumed by context-switching, increasing the likelihood of mistakes.

AR consolidates this process into a single, intuitive workflow. An engineer wearing AR smart glasses sees exactly which part to select, its correct placement, and even the required torque specification for a fastener, all without looking away from the work itself.

That direct overlay of digital information onto the physical world is the key. It turns a complicated manual into a simple, guided experience. This approach has been shown to reduce assembly errors by up to 90% in certain industrial settings.

This not only prevents mistakes but also dramatically accelerates the entire build process. Technicians spend less time deciphering diagrams and more time executing tasks with confidence.

Choosing the Right Tools for the Job

Implementing AR for assembly requires a thoughtful approach to both hardware and software selection.

Hardware Selection:

- Monocular Smart Glasses: These display information for one eye and are effective for delivering simple alerts, checklists, or text instructions without obstructing the user's view.

- Binocular Smart Glasses: Offering a more immersive experience, these glasses project 3D holograms and complex visuals across the user's full field of view, making them ideal for intricate assembly tasks requiring spatial awareness.

Software Integration:

For AR to be effective, it must integrate seamlessly with existing systems. Your AR software must connect with your Product Lifecycle Management (PLM) and Manufacturing Execution Systems (MES). This integration allows for the direct import of CAD models, parts lists, and procedures, ensuring that the AR instructions are always accurate and up-to-date.

Creating Digital Work Instructions That Actually Work

The power of AR is fully realized through well-designed digital work instructions. Simply converting a PDF manual for an AR headset is insufficient. Effective instructions are visual, interactive, and contextually aware. We have compiled a comprehensive guide on creating powerful work instructions for manufacturing that explores this process in detail.

For example, a technician assembling a custom gearbox with AR could experience the following:

- Visual Cueing: The system highlights the exact bin containing the next required part.

- Animated Guidance: A 3D animation demonstrates the precise orientation for installation.

- Automated Confirmation: On-screen confirmation is provided once the part is correctly seated, verified by computer vision or integrated sensors.

- Integrated Quality Checks: The CAD model is overlaid onto the physical part to instantly identify any misalignments, automating a quality control step.

This level of guidance empowers technicians of all skill levels to execute complex tasks accurately, leading to significant improvements in first-pass yield and overall speed. The global manufacturing landscape makes these efficiencies more critical than ever. As economic shifts, like those covered in reports on global manufacturing sentiment, create constant pressure to adapt, tools like AR help build a more resilient and efficient operation.

Accelerating Your Workforce with VR Training

The skills gap presents a significant challenge to manufacturing productivity. Recruiting experienced technicians is difficult, and training new hires on complex machinery is both time-consuming and costly.

Virtual Reality (VR) training offers a direct solution to this problem. It provides a safe, scalable, and highly effective method for developing a skilled workforce by moving training off the production floor and into a realistic, immersive simulation of the work environment.

VR closes the gap between theoretical knowledge and practical application—all without risk to personnel or expensive equipment.

Building Muscle Memory in a Risk-Free World

Traditional on-the-job training often involves a new hire shadowing a senior employee for weeks. This method is slow, can be inconsistent, and occupies the time of a valuable expert. VR disrupts this model by enabling trainees to learn by doing from their first day.

Consider a new operator learning to use a multi-axis CNC machine. In a VR simulation, they can practice the entire workflow—loading the workpiece, selecting tools, and running the program—repeatedly. If an error occurs, there is no scrapped material or costly machine damage. The user simply resets the scenario and tries again.

This process is ideal for building muscle memory for complex, hands-on tasks. Trainees can repeat difficult or hazardous procedures, such as a specific welding technique or a lockout-tagout protocol, until the actions become second nature.

The Real-World Payoff of Immersive Learning

Integrating VR into a training program delivers measurable gains in productivity. Immersive, hands-on learning has consistently been shown to be more effective for knowledge retention than passive methods like reading manuals.

Studies have demonstrated that trainees using VR can learn up to four times faster than in a traditional classroom setting. This means new hires can become productive, contributing members of the team in a fraction of the time.

The benefits extend beyond speed:

- Enhanced Safety: Simulating hazardous environments allows employees to practice emergency procedures and operate dangerous equipment without physical risk, proactively preventing accidents.

- Zero Equipment Downtime: Production continues uninterrupted, as physical machinery no longer needs to be taken offline for training purposes.

- Improved Skill Retention: The active, engaging nature of VR training embeds skills more deeply. Employees trained in VR demonstrate higher confidence and make fewer errors on the factory floor.

You can explore more about how this technology is transforming industrial training by examining the core benefits of virtual reality training.

Pinpointing Your Highest-Impact Training Needs

To maximize the return on your VR investment, a strategic approach is necessary. Instead of virtualizing all training, focus on areas where current methods are least effective.

Begin by identifying roles with the longest ramp-up times, procedures that result in the most errors, or tasks that carry the highest safety risks. These are prime candidates for VR training modules.

Analyze your production data. Identify your bottlenecks and the mistakes that lead to the most rework or scrap. For instance, if a specific assembly step is a persistent quality control issue, a targeted VR module offering detailed, repetitive practice could provide a permanent solution.

By integrating VR into your onboarding and continuous development programs, you are not just training people faster—you are building a more skilled, confident, and adaptable workforce. This approach boosts productivity today and establishes a foundation for operational excellence tomorrow.

Bolstering Maintenance and Quality Control with AR

Beyond assembly, two of the most critical areas in manufacturing are maintenance and quality control. A single machine failure or a minor defect can initiate a chain reaction, leading to significant downtime and costly rework. Augmented Reality provides immediate productivity gains in these areas by delivering digital intelligence directly into the line of sight of technicians and inspectors.

AR bridges the gap between complex digital schematics and the physical machinery on the factory floor. It also connects a junior technician with a seasoned expert who may be located thousands of miles away, transforming reactive processes into proactive, data-driven operations.

Slashing Downtime with Remote Expert Assistance

When critical machinery fails, every minute of downtime translates to lost revenue. The traditional solution—flying in a senior expert—can take hours or days and incur substantial travel expenses.

AR-powered remote assistance modernizes this outdated model. A junior technician encountering a complex fault can wear AR smart glasses and initiate a video call with a senior engineer.

The expert sees exactly what the technician sees in real-time, but the capabilities extend far beyond a simple video chat. The expert can:

- Draw digital annotations directly into the technician’s field of view, circling the specific valve to turn or the component to inspect.

- Share 3D models or schematics, overlaying them onto the physical machine for clear, contextual guidance.

- Freeze the video feed to highlight a specific detail and walk the technician through a complex repair sequence.

This “see-what-I-see” functionality acts as a force multiplier for your most skilled employees, allowing one expert to support multiple sites in a single day. This dramatically reduces machine downtime and travel costs while serving as a powerful on-the-job training tool.

This approach has been shown to reduce service times by 50% or more and decrease expert travel by over 75%. This is a fundamental change in maintenance strategy that directly boosts productivity in manufacturing.

Achieving Flawless Quality Control with Digital Overlays

Quality control demands absolute precision. Even the smallest deviation from specifications can result in a rejected part. Traditional inspection methods, which rely on manual measurements and comparisons to 2D drawings, are prone to human error.

AR introduces a new level of precision to the inspection process. An inspector wearing smart glasses can view a finished part and see a to-scale 3D digital overlay of its CAD model projected directly onto it.

This makes defect identification instantaneous and nearly foolproof.

- Deviation Highlighting: The AR software can automatically highlight any areas where the physical part deviates from its digital twin, flagging misalignments or missing components that might be missed by the human eye.

- Guided Inspections: Technicians can follow a sequence of AR-guided checkpoints, ensuring every critical feature is inspected in the correct order.

- Digital Documentation: The inspector can capture photos or record videos of defects directly through the glasses, with AR overlays included, creating a rich visual record for quality reports.

This method is not only faster but also significantly more accurate, removing ambiguity and ensuring every product meets exact design specifications before shipment.

Before discussing integration, it is useful to review the quantifiable impact of these technologies.

AR/VR Impact on Key Manufacturing Metrics

The following table summarizes typical productivity improvements observed in manufacturing operations after deploying AR and VR solutions. These figures represent real-world gains in efficiency, accuracy, and safety.

| Operational Area | Technology Applied | Average Productivity Gain | Key Benefit |

|---|---|---|---|

| Maintenance & Repair | AR Remote Assistance | 30-50% | Reduced machine downtime, lower travel costs. |

| Quality Assurance | AR Digital Overlays | 20-40% | Higher accuracy, fewer defects, faster inspection. |

| Complex Assembly | AR Work Instructions | 25-50% | Reduced error rates, faster onboarding. |

| Operator Training | VR Simulations | 40-60% | Improved skill retention, safer training environment. |

| Warehouse Operations | AR-guided Picking | 15-35% | Faster order fulfillment, fewer picking errors. |

As demonstrated, the gains are substantial and span multiple critical functions. By targeting the right areas, AR and VR become powerful drivers of operational excellence.

Practical Steps for AR Integration

Getting started with AR for maintenance and quality control is a focused process. The key is to identify specific pain points where the technology can deliver the most immediate and visible return.

- Pinpoint High-Impact Scenarios: Identify machines with the highest downtime rates or products with the most frequent quality control issues. These are ideal candidates for an initial AR pilot program.

- Choose the Right Hardware: For hands-on maintenance, ruggedized smart glasses with extended battery life are essential. For detailed quality inspections, a device with a high-resolution camera is required.

- Integrate with Your Existing Systems: The full potential of AR is realized when it is connected to your existing data sources, such as your ERP or PLM systems. This enables technicians to access work orders, schematics, and maintenance histories on demand.

By focusing on these practical applications, manufacturers can transform maintenance and quality control from cost centers into strategic advantages.

For a deeper analysis of this topic, we have prepared a comprehensive guide on the uses of augmented reality for maintenance that provides further details. This focused approach helps build a more resilient, efficient, and productive manufacturing operation.

Your Roadmap to AR/VR Integration

Integrating AR or VR into your manufacturing operations is a strategic initiative, not just a hardware purchase. A successful rollout is a carefully planned journey that minimizes disruption while building momentum and ensuring team adoption.

The goal is a phased, deliberate approach: start small, prove the value, and then scale intelligently. This methodology avoids overwhelming personnel and budgets, creating a sustainable path to real productivity gains.

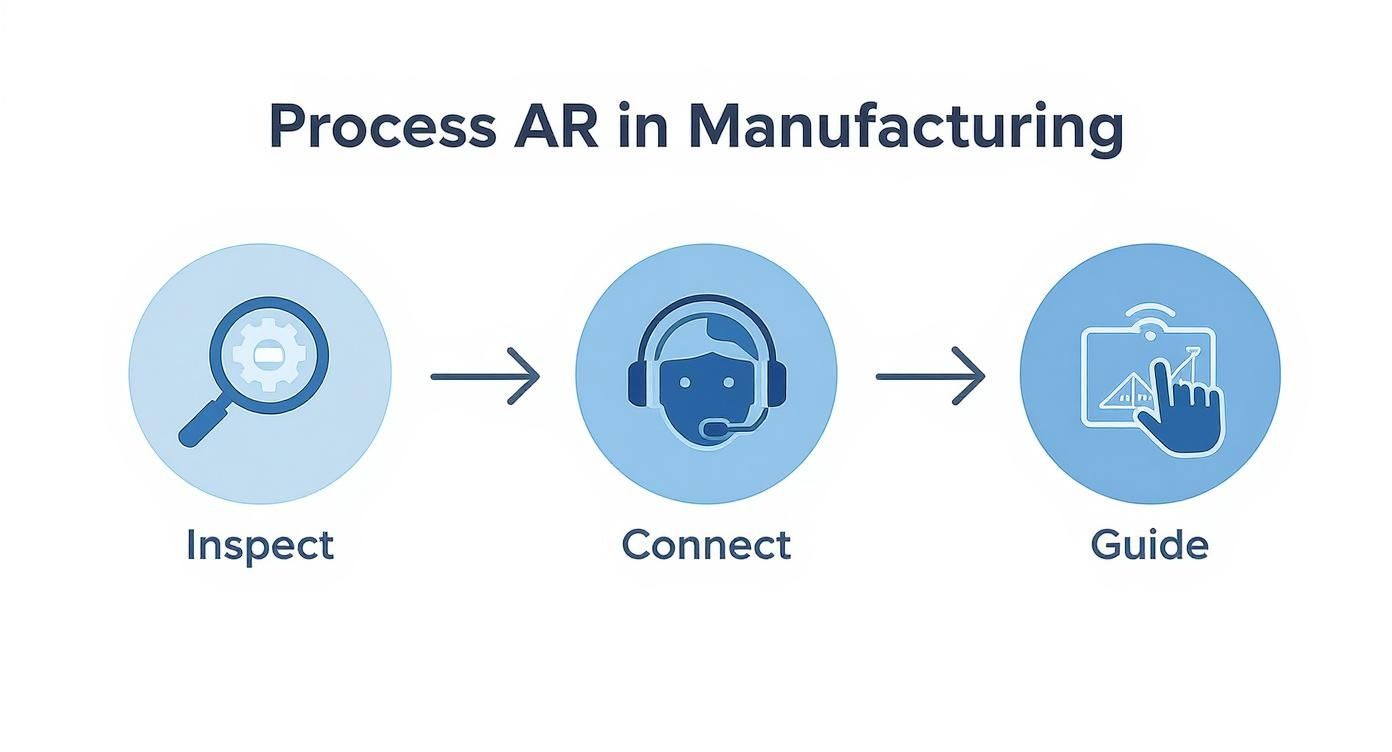

This visual illustrates how AR can inspect, connect, and guide your workforce, streamlining critical manufacturing tasks.

The flow moves from identifying problems to enabling remote collaboration and providing instructions exactly when and where they are needed.

Start with a Thorough Needs Analysis

Before considering any specific hardware or software, conduct a deep analysis of your current operations. Pinpoint the exact bottlenecks where AR or VR can deliver the greatest immediate impact. The objective is to apply the right solution to your most significant existing challenges.

Convene your operations, training, and quality control leaders. Walk the production floor with them and ask targeted questions:

- Where do our most frequent assembly errors occur?

- Which maintenance procedures cause the most significant production delays?

- Which training modules are most time-consuming for new hires?

- Which tasks require employees to frequently stop and consult a manual or schematic?

The answers will identify your most compelling use cases. If a specific multi-step assembly is a constant source of defects, AR-guided work instructions are an ideal solution. If training new welders is slow and costly, a VR training simulation is a logical choice.

Launch a Focused Pilot Project

Once you have identified a high-impact use case, launch a small, controlled pilot project. A pilot serves two critical functions: it proves the technology’s ROI on a limited scale and provides invaluable real-world feedback before a full-scale rollout.

Select a single workstation, a small team, or one specific machine for your test. Define clear, measurable KPIs to track progress, such as:

- Reduction in error rates

- Decrease in assembly or repair time

- Improvement in first-pass yield

- Faster completion of training modules

During the pilot, focus on the user experience. Is the headset comfortable for a full shift? Are the on-screen instructions intuitive? This feedback is essential for fine-tuning the solution before scaling.

A successful pilot project does more than just validate the technology; it creates internal champions. When other teams see the tangible benefits for themselves, they become your biggest advocates for a wider implementation.

Address Data Security and System Integration

For AR and VR to deliver maximum value, they must integrate with the systems that run your factory, such as your Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This integration enables a technician to access a real-time work order, check inventory levels, or view a digital twin directly on their headset, creating a seamless data flow.

Simultaneously, you must prioritize data security. You are deploying sensitive intellectual property—proprietary CAD models and manufacturing processes—onto new devices. Collaborate closely with your IT department to ensure the AR/VR solution meets all security protocols, including network security, device access management, and data encryption. This step is non-negotiable for protecting your competitive advantage.

Drive Adoption with Change Management

The final and most critical component is change management. The best technology is ineffective if your team does not use it. Effective change management relies on clear communication, comprehensive training, and demonstrating the direct benefits to employees.

Start by communicating the "why" behind the initiative. Explain how this technology will make their jobs easier, safer, and more efficient—not how it will replace them. Provide comprehensive, hands-on training that allows everyone to become comfortable with the equipment in a low-pressure environment.

Actively listen to feedback and address concerns directly. By involving your team in the process from the pilot phase onward, you build a sense of ownership. This collaborative approach turns potential resistance into active support, ensuring your AR/VR integration is a lasting success.

Common Questions About AR/VR in Manufacturing

Introducing new technology to the factory floor will naturally generate questions. When considering AR and VR to improve manufacturing productivity, leaders are rightfully curious about cost, team adoption, and the practicalities of implementation.

Let’s address some of the most common questions from organizations moving from consideration to action.

What Is the Real Cost to Get Started?

The initial investment for AR/VR is more flexible than many assume. A complete operational overhaul is not required from day one. The most cost-effective approach is to begin with a focused pilot program.

Initial costs can be categorized into three areas:

- Hardware: This includes AR smart glasses or VR headsets. The price per unit varies, but a pilot requires only enough devices for the initial team.

- Software and Licensing: This covers the platform for your digital work instructions, training simulations, or remote expert collaboration. Many providers offer subscription-based models, which reduces the upfront investment.

- Implementation and Content Creation: This includes the initial setup and the development of your first AR-guided procedure or VR training module.

By starting small and addressing a single, high-impact problem, you can control the initial expenditure while building a solid business case for future expansion.

How Can I Prove the Return on Investment?

Proving ROI is essential for securing project approval and is achievable with a well-planned pilot. The key is to define your success metrics before implementation. Avoid vague goals and track specific, quantifiable data.

For example, if you are piloting AR for a complex assembly task, measure the direct impact on your KPIs. Did you achieve a 25% reduction in assembly time? Did your first-pass yield increase by 15%? These tangible results make the investment case clear.

The most powerful ROI arguments come from a simple before-and-after. Measure your baseline performance on a task the old-fashioned way, then measure it again with the new tech. The gap between those two numbers is your immediate return.

The same principle applies to VR training. You can track how much faster new hires reach proficiency or quantify the reduction in material waste from practice errors. Presenting concrete figures like these demonstrates the clear value of the technology.

Will My Workforce Actually Use This Technology?

Team adoption depends more on your rollout strategy than on the technology itself. A common mistake is deploying new tools without context or employee input. To ensure your workforce embraces AR and VR, involve them in the process from the beginning.

Start by including your most experienced technicians in the pilot program. Their expertise is invaluable for refining the user experience, and their endorsement will influence their peers.

It is also crucial to explain the "why." Clarify that these tools are intended to make their jobs safer and easier, not to replace them. When an operator views AR as a tool that prevents errors and VR as a safe environment to master a skill, adoption occurs naturally.

Ready to see how immersive technology can transform your operations? At AIDAR Solutions, we specialize in creating AR and VR applications that deliver measurable productivity gains. Our experts work with you to identify the highest-impact use cases and build a clear roadmap for success. Discover our solutions today.