Virtual Reality for Industry Transformation Guide

For years, virtual reality in the industrial world felt more like a futuristic concept than a practical tool. That perception has changed. Today, VR is a hands-on solution actively solving major business challenges on the factory floor and in the design studio.

The core principle is creating fully immersive, computer-generated environments that act as digital replicas of real-world machinery, workflows, and entire facilities. This allows teams to engage in safer training, faster prototyping, and more efficient operations—all without the physical risks or significant costs associated with traditional methods.

How VR Is Changing Industrial Operations

Industrial VR is delivering real, measurable results by creating a "digital twin" of a workspace, a complex piece of equipment, or a full production line. This virtual space becomes a risk-free environment for development and training.

In this digital replica, employees can learn new skills, engineers can test innovative designs, and teams can collaborate from across the globe, all without interrupting active operations. It represents a fundamental shift in how industrial companies are approaching their core functions.

Instead of relying solely on manuals or classroom sessions, businesses are now using immersive simulations. This is not about adopting new technology for its own sake; it is a strategic move to build a more skilled, resilient, and efficient workforce.

The Core Benefits of Industrial VR

The adoption of virtual reality is driven by significant, bottom-line advantages. Companies are realizing substantial improvements in critical operational areas.

Accelerated Skill Development

With immersive training, employees can practice complex tasks repeatedly in a completely safe environment. This builds procedural memory and confidence far more effectively than traditional methods.

Enhanced Operational Safety

Hazardous scenarios—such as emergency shutdowns or equipment malfunctions—can be simulated without anyone being in harm's way. This approach drastically reduces the risk of accidents and injuries, both during training and in day-to-day operations.

Significant Cost Reduction

VR minimizes the need for expensive physical prototypes. It also eliminates the need to shut down revenue-generating equipment for training sessions or fly an expert across the world for a consultation.

These are not minor improvements. The global VR market is expected to reach USD 330.27 billion by 2033, largely driven by enterprise adoption. More importantly, VR training has been shown to boost learning effectiveness by up to 76% over traditional methods. Its impact on workforce education is undeniable. You can dive deeper into the rise of new technologies in manufacturing in our detailed guide.

Think of it this way: Virtual Reality is a flight simulator for the factory floor. It gives your team the space to practice, fail, and ultimately master their roles in a completely safe, controlled digital environment. When they face a challenge in the real world, they're already prepared.

To help you see how these pieces fit together, we’ve broken down the most common applications and the problems they solve.

Core Industrial VR Applications at a Glance

This table maps out the primary uses for VR in an industrial setting and highlights the specific business pain points each one addresses.

| VR Application | Business Problem Solved | Primary Benefit |

|---|---|---|

| Immersive Safety Training | High-risk, low-frequency events that are hard to train for physically. | Drastically reduces accidents and injuries by building muscle memory for emergency procedures. |

| Technical Skill Development | Long learning curves for complex machinery and assembly tasks. | Speeds up employee ramp-up time and improves first-time quality rates. |

| Remote Maintenance & Support | Delays and travel costs associated with getting expert help on-site. | Enables real-time expert guidance for local technicians, minimizing downtime. |

| Virtual Prototyping | High costs and slow timelines of building and iterating physical prototypes. | Allows for rapid design validation and ergonomic testing before any metal is cut. |

| Onboarding & Orientation | Inconsistent or overwhelming onboarding experiences for new hires. | Provides a standardized, engaging introduction to the facility and company culture. |

As you can see, each application is directly tied to solving a real, costly problem that nearly every industrial operation faces.

A Strategic Asset for Gaining an Edge

Ultimately, integrating virtual reality into your operations is about building a competitive advantage. The companies that implement this technology effectively are those that can onboard new hires faster, bring better products to market quicker, and resolve maintenance issues before they become critical failures.

As industrial processes become more complex, the ability to see, practice, and perfect them in a virtual space becomes a game-changer. This technology gives your teams the power to spot bottlenecks before they happen, test the ergonomics of a new assembly line, and get expert guidance to a technician on a remote site in seconds.

By focusing on what VR actually does—solving real problems—it ceases to be an expense and becomes a critical investment in your company's future.

Building a Safer Workforce with Immersive Training

Consider how pilots are trained; they don't earn their wings just by reading books. Yet, many high-stakes industrial jobs still rely on similarly passive training methods. Manuals and slideshows are insufficient to prepare people for the complex, and often dangerous, reality of the factory floor. This is where industrial VR makes its most significant and proven impact.

VR training functions as a "flight simulator" for critical industrial tasks. It places employees into a fully immersive, zero-risk environment where they can master everything from complex assembly procedures to emergency shutdown protocols. In this digital world, mistakes are not just allowed—they are valuable learning opportunities that carry zero real-world consequences.

This type of hands-on practice is fundamentally different from passive learning. When an employee physically performs the motions of a task in VR, they build muscle memory. This deep, kinesthetic learning dramatically increases knowledge retention, ensuring that when a real emergency occurs, the correct response is instinctual.

Mastering High-Stakes Scenarios Safely

Some of the most critical jobs on the floor are also the most difficult to practice. It is not feasible to start a fire or trigger an equipment failure to test a team's reaction. VR removes this barrier completely.

With VR simulations, you can replicate rare but catastrophic events, allowing teams to run through emergency responses until they are flawless. This level of preparation builds a degree of skill and confidence that is simply impossible to achieve otherwise. The result is a team that is not only proficient at daily tasks but also genuinely prepared for the unexpected.

For example, a new hire can practice handling hazardous materials without ever being near a real chemical. A maintenance crew can rehearse a complex lockout/tagout procedure on a perfect digital twin of a machine, eliminating the risk of accidental energy discharge.

By creating a space for unlimited, risk-free repetition, VR transforms training from a compliance exercise into a powerful tool for building genuine expertise. Employees don't just learn the steps; they internalize the process.

Accelerating Onboarding and Skill Acquisition

Getting new hires up to speed quickly is a persistent challenge for industrial companies. A slow or inconsistent onboarding process leads to lost productivity and potential safety risks. VR training addresses this by offering a standardized, engaging, and highly effective learning path.

From day one, a new assembly line worker can step into a virtual replica of their workstation. Guided by interactive instructions and instant feedback, they can practice their tasks repeatedly before touching the physical equipment.

This approach significantly shortens the learning curve. Studies show VR learners can be trained up to four times faster than their classroom-trained counterparts. This not only allows new team members to become productive sooner but also frees up senior staff from conducting repetitive basic training sessions. To get a better sense of the specific advantages, check out the many benefits of virtual reality training we've detailed in our comprehensive overview.

The Tangible Impact of Immersive Practice

When companies adopt VR training, they see measurable improvements across the board. By moving beyond theory and into hands-on application, they build a more resilient and capable workforce.

- Reduced Human Error: Immersive practice reinforces correct procedures, leading to a significant drop in costly and dangerous on-the-job mistakes.

- Increased Confidence: Employees who have successfully handled complex scenarios in a simulation are far more confident and decisive when facing them in reality.

- Improved Safety Records: The ability to train for hazardous situations in a completely safe space directly translates to fewer workplace accidents and injuries.

Ultimately, using industrial VR for training is more than an investment in technology. It is a strategic investment in your most valuable asset: your people. By providing them with the best possible tools to learn and master their jobs, you build a foundation for a safer, more efficient, and more productive operation.

Designing the Future with Virtual Prototypes

The traditional product development process can be slow and expensive. It often involves a lengthy cycle of building physical prototypes, shipping them for feedback, and making costly adjustments late in development. Virtual reality doesn't just improve this process—it fundamentally redesigns it, collapsing development timelines and reducing prototyping costs.

The advantage of virtual reality for industry during the design phase is its ability to allow teams to literally step inside their 1:1 scale digital designs before a single physical part is manufactured.

This immersive collaboration is a game-changer. Engineers, designers, and customers can walk around a virtual model of a new machine, inspecting it from every angle. This makes spotting potential design flaws, testing ergonomics, and validating assembly steps in a shared virtual space nearly effortless.

Collaborative Design in a Shared Virtual Space

One of the greatest benefits of virtual prototyping is the ability to bring all stakeholders together, regardless of their physical location. An engineer in Germany, a designer in Japan, and a manufacturing lead in the United States can all meet inside the same virtual model simultaneously.

This immediate, global teamwork accelerates innovation. Instead of waiting weeks for feedback on a physical model, stakeholders can provide input instantly. This leads to faster iterations and a more refined final product.

Virtual prototyping allows teams to fail faster and at a lower cost. Identifying a design flaw in a digital model costs very little to fix. Discovering the same issue in a physical prototype can set a project back by months and significant capital.

The industry has taken notice. Extended reality (XR) markets are expanding rapidly, largely due to industrial adoption. Enterprise use now drives an estimated 60% of total industry revenue, signaling a massive corporate vote of confidence in VR for manufacturing and design.

From Digital Twin to Market-Ready Product

These virtual prototypes are not just static 3D models. They are dynamic digital twins that can be tested and validated under simulated real-world conditions long before production begins. For more information on this concept, we’ve covered some other powerful digital twin examples in a separate article.

Key validation checks that can be performed in VR include:

- Ergonomic Testing: Teams can visualize how a worker will interact with a machine, ensuring controls are accessible and tasks can be performed safely and comfortably.

- Assembly and Maintenance Simulation: Technicians can practice building or servicing the virtual product, identifying challenges and refining the design for easier maintenance.

- Performance Analysis: By integrating with physics engines, teams can simulate how a product will perform under stress, optimizing it for durability and efficiency.

Identifying these issues early in a virtual environment ensures the final product is optimized for manufacturing, performance, and the end-user. This approach not only saves a tremendous amount of time and money but also leads to better, more reliable products reaching the market faster.

Making Maintenance and Repairs Faster and Smarter with VR

Downtime is a direct threat to productivity. When critical machinery goes offline, every second translates to lost revenue. Traditional methods—consulting dense paper manuals or waiting for a senior expert to travel to the site—are often inefficient.

Virtual reality fundamentally changes this dynamic. It transforms Maintenance, Repair, and Operations (MRO) from a slow, often frustrating process into a faster, more accurate, and less stressful one.

Imagine a technician wearing a VR headset, looking at a complex hydraulic pump. Instead of referencing a manual, they see animated, step-by-step digital guides overlaid in their view, showing them exactly what to do. That is the power of virtual reality for industry—it delivers expert guidance precisely when and where it's needed most.

This approach significantly reduces human error, a major cause of extended downtime and repeat repairs. By following precise visual cues, even a junior technician can perform complex jobs with the confidence of an experienced professional. This not only gets machinery back online faster but also empowers a less experienced workforce to handle a wider range of issues.

Bridging the Skills Gap with Remote Experts

One of the most powerful applications of VR in maintenance is remote assistance. A technician on a remote oil rig or in a factory across the country can instantly connect with a senior engineer located in an office thousands of miles away.

Through the technician’s headset, the off-site expert sees exactly what the technician sees in real-time. The expert can then annotate the technician’s view, highlighting specific bolts, circling a faulty component, or displaying a schematic next to the machine. This "see-what-I-see" capability eliminates miscommunication and ensures problems are resolved correctly the first time.

Remote VR assistance essentially teleports your best expert to any job site in the world, instantly. It can reduce equipment downtime by up to 50% and eliminates the significant costs and logistical challenges of flying experts to sites.

The Real-World Payoff of VR-Guided Maintenance

Integrating VR into MRO workflows delivers clear, measurable results that directly impact the bottom line. Companies that adopt this technology realize significant gains in several key areas.

- Dramatically Less Downtime: Faster problem-solving and guided repairs mean equipment is back online in a fraction of the time, directly boosting operational efficiency.

- Better First-Time Fix Rates: With expert oversight and clear visual instructions, technicians are far more likely to complete the job correctly on the first attempt, avoiding costly return visits.

- Safer Technicians: VR can guide workers through hazardous procedures like lockout/tagout, ensuring every safety step is followed in the correct sequence.

- Empowered Junior Staff: New technicians become productive team members much faster because they can confidently take on complex jobs with virtual expert support.

The use of virtual reality in industry is gaining momentum, fueled by more affordable hardware and a growing ecosystem of powerful business software. VR is making a real impact in sectors like automotive and manufacturing because it helps companies save money, improve workflows, and upskill their employees.

While VR creates a fully immersive digital world, it is worth noting that related technologies offer similar benefits. For a closer look at how digital information can be overlaid onto the real world, our guide on augmented reality for maintenance offers valuable insights. Ultimately, these tools are about getting the right information to the right person at the right time, turning complex repairs into simple, manageable steps.

Creating a Practical VR Implementation Roadmap

Moving from the concept of industrial VR to a successful, on-the-floor reality requires a strategic plan. Simply purchasing headsets without a clear goal is a recipe for wasted investment and low adoption. A well-defined roadmap ensures your VR project aligns with business objectives and delivers measurable results.

Implementation should start with a problem, not a piece of technology. Identify a specific, high-impact challenge in your operations that VR is well-suited to address. This could be a critical safety training gap, a major bottleneck in your design process, or costly downtime from complex repairs. Focusing on a single, urgent need provides your pilot program with a clear purpose.

Once the problem is identified, you must define what success looks like. Before starting, establish clear, quantifiable metrics. Consider goals like a 20% reduction in training time for new hires, a 15% decrease in assembly errors, or a 30% faster response time for critical maintenance. These benchmarks will be crucial for proving ROI.

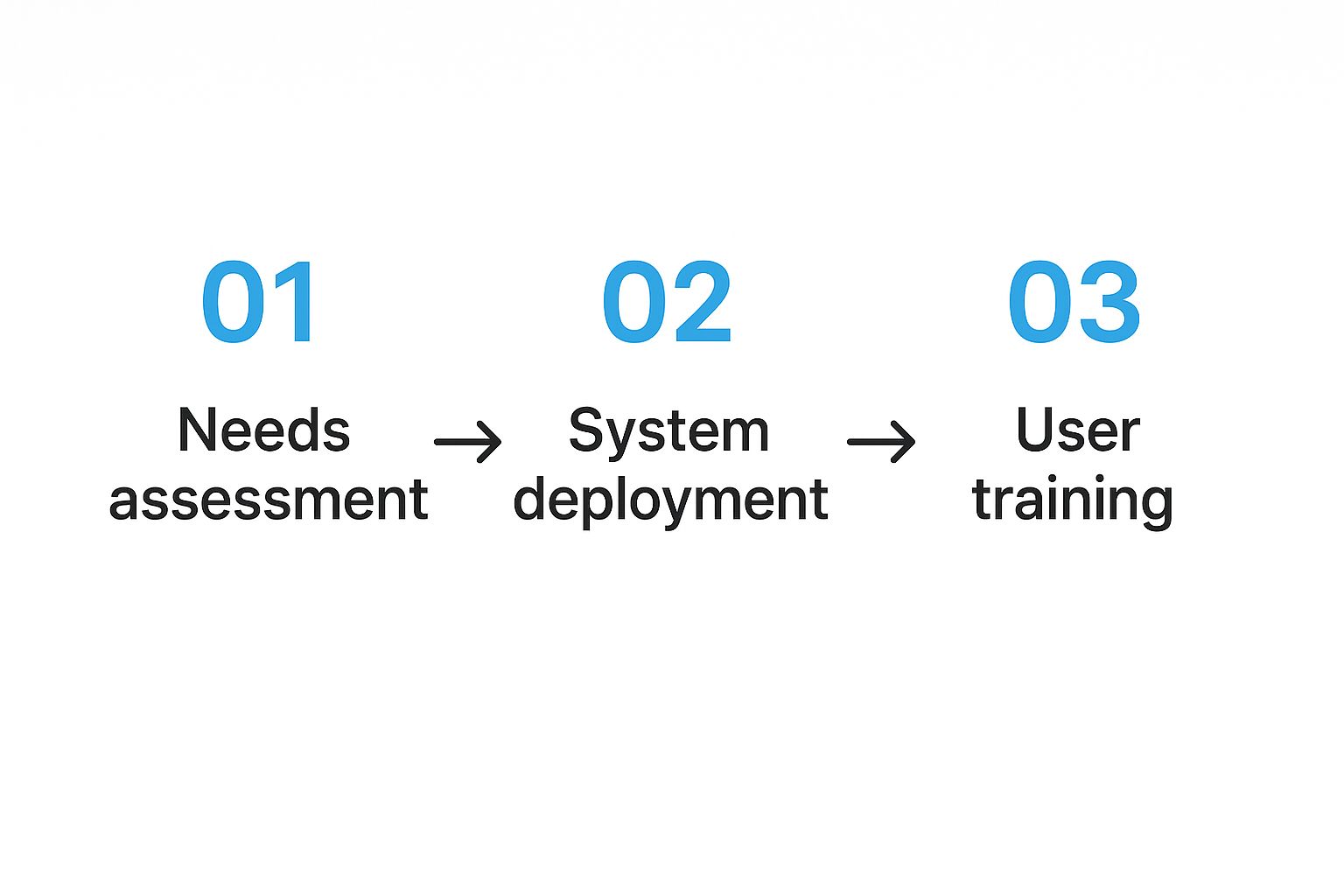

The infographic below illustrates the basic steps for a sound VR integration.

As shown, technology selection is not the first step. It is the solution that comes after a thorough assessment of your operational and personnel needs.

Selecting the Right Tools for the Job

With your goals established, it's time to choose the appropriate hardware and software. The hardware—whether powerful PC-tethered headsets or more flexible standalone devices—depends entirely on your use case. A complex design review likely requires the high-fidelity graphics of a tethered system, while a field maintenance application demands portability.

The software decision is equally important. You need to determine if an off-the-shelf solution can meet your needs or if you require a custom application to accurately replicate your unique machines and workflows. For a broader perspective on this type of strategic planning, understanding how to build a complete digital transformation roadmap can offer valuable context.

A common mistake is to acquire the technology first and then search for a problem to solve. A successful VR implementation starts with the business challenge, not the headset.

Choosing between a ready-made VR platform and custom development can be a difficult decision. Here is a brief comparison to help you weigh the pros and cons of each approach.

Comparing VR Software Implementation Approaches

| Consideration | Off-the-Shelf Solution | Custom Development |

|---|---|---|

| Speed to Deployment | Fast, often ready to use within days or weeks. | Slower, requiring months for development and testing. |

| Cost | Lower initial investment, typically a subscription fee. | Higher upfront cost for development and ongoing maintenance. |

| Specificity | General features may not perfectly match unique workflows. | Precisely tailored to replicate your exact equipment and processes. |

| Scalability | Easy to scale licenses, but features are fixed. | Can be scaled and adapted as your operational needs evolve. |

Ultimately, the right choice depends on your specific needs, budget, and timeline. An off-the-shelf solution is excellent for getting started quickly, while custom development offers a perfect fit for highly specialized operations.

Driving Adoption and Measuring Success

A successful rollout ultimately depends on people. Change management is critical. Involve your end-users early to build enthusiasm and gather their feedback. Your training plan should not just cover how to use the headset—it needs to demonstrate how this new tool makes their jobs easier, safer, and more effective.

Start with a small, focused pilot program. This allows you to test your approach, collect data against your predefined metrics, and resolve any issues before committing to a large-scale rollout. This phased method de-risks the investment and builds a solid business case for expanding VR throughout the organization.

Frequently Asked Questions About Industrial VR

Even with numerous success stories, adopting industrial VR naturally raises practical questions. Business leaders want to understand the real-world implications, from the initial investment to the long-term value.

Let's address the most common questions to provide the clear answers needed for an informed decision.

What is the typical cost to get started with industrial VR?

The honest answer is that the cost depends entirely on the objective. The investment can vary significantly.

For an initial exploration, a simple pilot program is an excellent starting point. This might only require a few standalone headsets and an off-the-shelf software license to test a single training module. This approach minimizes the upfront cost while you prove the concept and gather data.

Conversely, a large-scale rollout with custom software designed to perfectly replicate your unique machinery represents a more substantial investment. The cost is always tied to the complexity and scale of the problem you are solving.

Key Takeaway: The barrier to entry is more flexible than many assume. A focused, high-impact pilot program is a cost-effective way to prove the value of VR before making a larger commitment.

How quickly can we expect to see a return on investment?

The ROI on industrial VR can be realized surprisingly quickly because it directly addresses high-cost, high-impact areas of the business. Some organizations see a return within the first year, simply by reducing travel costs for expert technicians or by preventing a single serious workplace accident through improved safety training.

The most consistent gains, however, come from operational efficiency. The key metrics to monitor are:

- Reduced Training Time: Cutting onboarding time by 50% yields a significant productivity gain from the outset.

- Lower Error Rates: Fewer mistakes on the assembly line mean less material waste and fewer hours spent on rework.

- Minimized Downtime: When repairs are faster and more accurate, your most critical assets are back online in record time.

Once you begin tracking these metrics, the financial benefits become clear very quickly.

Can VR integrate with our existing enterprise systems?

Yes. Modern industrial VR platforms are designed to integrate with existing enterprise technologies. This integration is often where the greatest value is realized.

For example, a VR training application can connect to your Learning Management System (LMS) to track employee progress and completions, just like any other e-learning course.

In a maintenance context, VR applications can sync with your Enterprise Asset Management (EAM) system, pulling work orders and live equipment data directly into the virtual environment. This ensures the technician is always working with accurate, up-to-the-minute information. VR becomes a seamless part of their workflow, not an additional, disconnected tool.

Ready to see how AIDAR Solutions can deliver a measurable return on investment for your operations? Our experts can help you build a practical implementation roadmap that aligns with your business goals. Discover our tailored VR and AR applications by visiting us at https://aidarsolutions.com.