Augmented Reality for Manufacturing: Boost Efficiency & Safety

What if you could give every technician on your floor the eyes and knowledge of your most seasoned expert? That’s not science fiction anymore. Augmented reality for manufacturing is making it happen, bridging the frustrating gap between a digital blueprint and the physical workpiece.

Think of it as an interactive GPS for complex machinery, overlaying real-time instructions and critical data directly onto a worker’s line of sight.

Bringing Digital Intelligence to the Physical World

Augmented reality (AR) has officially left the realm of futuristic tech demos and become a rugged, practical tool for solving today’s biggest factory-floor headaches. Manufacturers are in a constant battle against skills gaps, costly production errors, and persistent safety risks. AR addresses these challenges by changing how people interact with their work environment.

Instead of flipping through a binder or walking over to a computer terminal, operators can use smart glasses or tablets to see the information they need, exactly when and where they need it. This digital overlay gives them context-aware guidance that makes complicated jobs feel simple and clears up mental clutter. The result? A workforce that’s more capable, more confident, and a whole lot more efficient.

A New Way of Working

The real magic of AR in manufacturing is its ability to deliver the right information at the right moment. This instant access to data completely retools how things get done:

- Learning on the Fly: New hires can follow step-by-step visual guides that are projected right onto their task, slashing the time it takes to get up to speed.

- Slashing Human Error: By overlaying a digital template onto a physical part, AR guides the worker to perform the task correctly the first time.

- Boosting Safety: AR can actively highlight unseen hazards, pop up emergency procedures, or walk someone through a safety checklist in real-time. It’s a surefire way to build a safer workplace.

AR gives every worker the knowledge of your best engineer, available on demand. It pulls critical information out of static screens and binders and puts it directly into the active workspace, making every action more intuitive and precise.

A Practical Tool That Delivers Real Results

This isn't about chasing the latest tech trend. It's about giving your team a tool that delivers tangible, measurable improvements from day one. It's like giving them a new kind of vision—one that can see digital schematics, live diagnostic data, and expert guidance all at once.

Picture a quality control inspector. Instead of squinting at a part and comparing it to a drawing, they can hold up an AR-enabled tablet and instantly see the digital twin overlaid on the physical product. Any deviation or defect lights up immediately, catching issues that the human eye might have missed.

This is the core value of AR: it shifts the factory from a reactive, problem-solving model to a proactive, guided one. It’s the foundation for a smarter, more connected manufacturing floor.

How AR Technology Works in an Industrial Setting

Think of augmented reality in a manufacturing setting as a transparent, intelligent layer that sits right on top of the real world. It doesn't replace what a worker sees; it enhances it, adding critical digital information directly into their line of sight. This creates a powerful mixed-reality environment where physical machinery and digital data coexist.

At its heart, the system is a team effort between a few key components. It all starts with a device—maybe ruggedized smart glasses, a tablet, or even a smartphone—equipped with a camera and sensors. This device acts as the eyes, capturing a live view of a machine or a complex part on the assembly line.

At the same time, specialized software kicks in to recognize whatever the camera is pointed at. Using computer vision and object recognition, it figures out what it's "seeing." This is the key moment that allows it to precisely overlay the right digital content, like 3D models, step-by-step instructions, or real-time performance data, right onto the live view.

The Core Components of an AR System

You can picture an industrial AR setup as a team of specialists working together to give instant, on-the-spot guidance. Every part has a specific job, and they all need to be perfectly in sync to create a smooth experience for the person on the floor. It’s this blend of hardware and software that turns a complex piece of equipment into an interactive, digital-age instruction manual.

Here are the primary players:

- Display Hardware: This is the window to the augmented world. It could be a hands-free headset like smart glasses, which is great for letting operators keep both hands on their work. Or it might be a more familiar industrial-grade tablet, perfect for mobility and getting a detailed look at things.

- Tracking and Sensing Technology: This is where the smarts come in. Sophisticated sensors, like gyroscopes and accelerometers, work with the camera to track the user's position and orientation. This ensures the digital overlay stays locked in place, perfectly aligned with the real-world machinery, even as the worker moves around.

- Processing Software: This is the brains of the whole operation. The software takes the camera feed, identifies the object, grabs the right information from a database (like a CAD file or work instructions), and renders the digital overlay in real-time.

This technology is already making waves economically. Extended Reality (XR), the umbrella term that includes AR, is set to give the global economy a serious boost by making manufacturing more productive. In fact, projections show that XR applications could add $360 billion to the global GDP by 2030, just by improving processes like complex assembly and remote expert support. For instance, companies use AR glasses to give workers visual, step-by-step instructions, which makes tricky tasks simpler while boosting both accuracy and safety.

From Digital Data to Physical Action

So what does this actually look like on the factory floor? Imagine a technician needs to run a maintenance check on a hydraulic press. Instead of digging out a thick, paper manual, they just pop on a pair of smart glasses.

The AR system instantly recognizes the machine. Glowing arrows appear, pointing to the exact inspection points. As the technician moves to each point, the system displays the required pressure reading and even shows a short video of the correct procedure.

This whole process cuts out the guesswork and drastically reduces the chance of human error. The system is essentially an expert whispering in the technician’s ear while showing them exactly what to do. The benefits are obvious, as this approach completely changes how information is delivered and used on the factory floor. You can dive deeper into this topic in our guide on how augmented reality changes industrial work.

This seamless fusion of digital guidance and physical work is the real power of augmented reality for manufacturing. It empowers workers to tackle complex jobs with more speed, precision, and confidence than ever before, setting the stage for the specific, high-impact applications we'll explore next.

Practical Use Cases for AR in Manufacturing

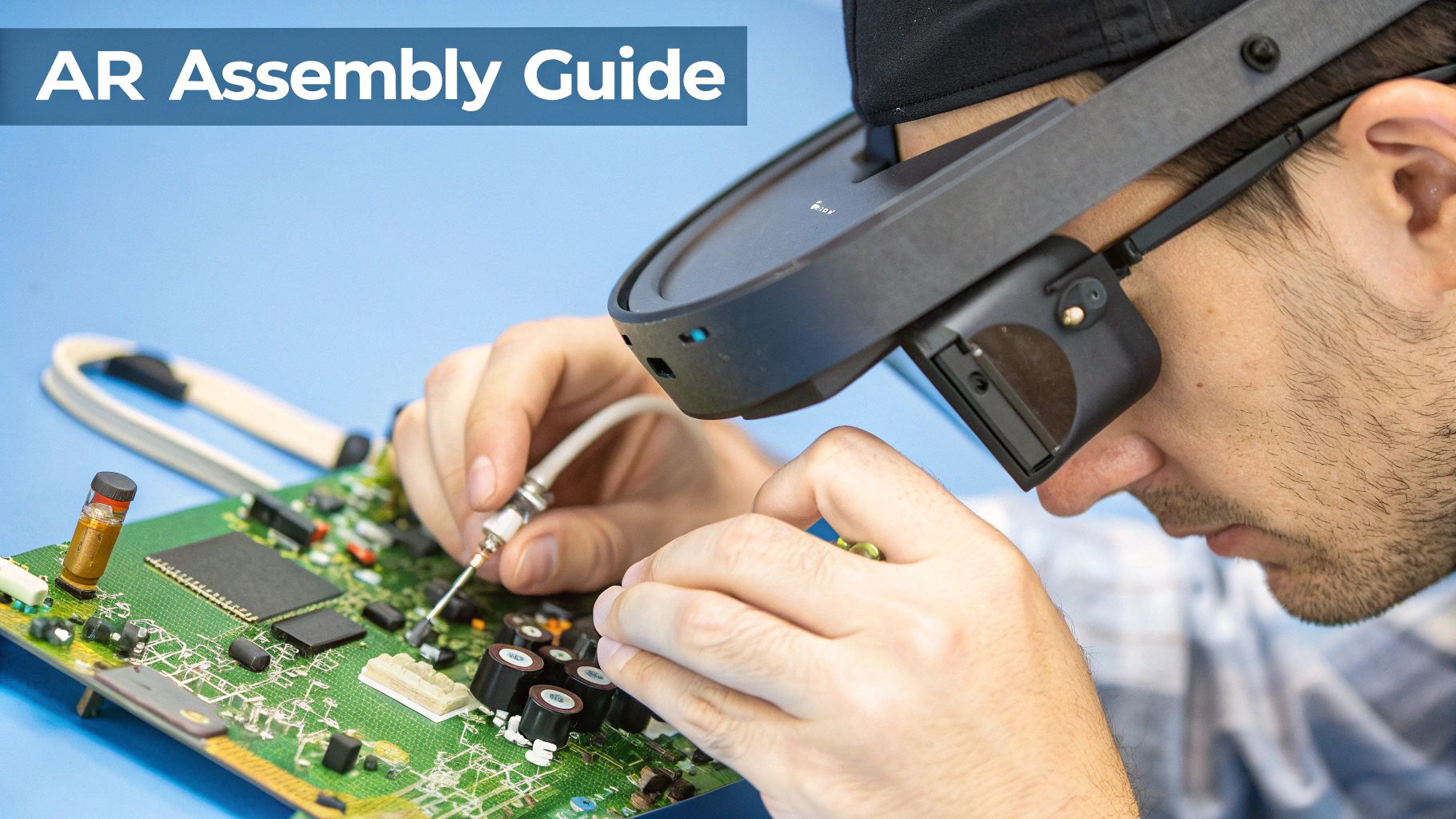

This is where the theory hits the factory floor. The image here is a perfect example—AR isn't about replacing the real world; it's about making it smarter by overlaying crucial data right where you need it. This simple act of blending digital information with physical machinery turns complex jobs into straightforward, guided experiences.

Now that we've covered the "how," let's dig into the "where." The real power of augmented reality for manufacturing is its sheer versatility. This isn't a one-trick pony. It’s a flexible platform that tackles some of the industry's toughest, most persistent headaches, from assembling mind-bogglingly complex products to fixing a critical machine in a hurry.

These applications show AR evolving from a cool concept into an essential tool for modern operations.

Guided Complex Assembly

Picture this: you're tasked with assembling a product made of thousands of tiny, intricate parts. The old way? You’re juggling bulky paper manuals or squinting at 2D diagrams on a screen, constantly shifting your focus back and forth. That mental gymnastics is what leads to mistakes, costly rework, and delays.

AR completely changes the game. It overlays step-by-step instructions directly onto the workpiece. A technician wearing smart glasses sees digital guides, animations, and tool prompts exactly where they're needed, in their line of sight.

For example, an aerospace technician can see a 3D animation showing the correct sequence for installing bolts on an engine. The AR system can highlight the precise location for each part and even give a green checkmark when a step is done right. What was once a complex, error-prone task becomes a simple, guided process, dramatically cutting assembly time and boosting first-time quality.

Real-Time Quality Control

Quality control is non-negotiable, but it's often a massive bottleneck. Inspectors typically have to compare a finished product against a detailed blueprint or a CAD model on a separate screen. It's a manual, painstaking process where it’s all too easy to miss subtle defects.

With augmented reality, you're essentially giving your QC team superpowers. An inspector can use an AR-enabled tablet or headset to superimpose a perfect digital model right over the physical product.

This digital overlay instantly flags any deviation from the spec. Misaligned components, missing parts, or even microscopic surface flaws become immediately obvious, often highlighted in red right on the inspector's screen.

This lets them catch and correct defects on the spot, preventing a faulty product from ever making it down the line. It's not just faster; it creates a rich data trail. Every defect can be logged automatically with photos and precise location data, feeding invaluable insights back into the production process.

Streamlined Maintenance and Repair

When a critical machine breaks down, the clock is ticking. Every minute of downtime is burning cash. Too often, technicians waste precious time just diagnosing the issue—hunting for the right manual or schematic.

AR makes the entire maintenance workflow faster and way more intuitive. A technician can just point their device at a piece of equipment to instantly pull up its entire service history, real-time performance data, and digital manuals. The system can overlay electrical schematics, highlight problem areas flagged by IoT sensors, and even play step-by-step video instructions for the repair.

Imagine a field tech working on a huge, complex HVAC unit. With AR glasses, they see a digital overlay showing them exactly which panel to open, which wires to test, and what the voltage readings should be. It effectively turns every technician into an expert, slashing repair times and reducing the need to fly in a senior specialist for every little problem.

Instant Remote Expert Support

Of course, some breakdowns are just too complex for the on-site team. In the past, the only option was to fly in a subject matter expert, which could take days and cost a fortune. AR-powered remote assistance completely flips that script.

A frontline worker can fire up a video call with an expert anywhere in the world. Through the on-site technician's AR device, the remote expert sees exactly what they see, in real-time. The expert can then draw, circle, and drop instructions right into the technician's field of view, guiding them through the fix as if they were standing right there.

Many of these hands-on AR applications are perfect for optimizing processes within the manufacturing industry, building more efficient and resilient operations.

Immersive Employee Training

Getting new employees up to speed on complex machinery can be slow, expensive, and frankly, a bit dangerous. Traditional training often means shadowing an experienced worker or practicing on live, production-critical equipment where a mistake can be disastrous.

AR offers a much safer, more effective path. New hires can learn in a controlled, simulated environment. Here, they can practice complex assembly or maintenance procedures without any risk to themselves or the expensive machinery. It allows them to get hands-on and build muscle memory in a way that reading a manual never could.

Trainees can repeat modules as many times as they need to build confidence before ever stepping onto the factory floor. The result? They get up to speed faster, retain more information, and are better prepared from day one.

Measuring the Business Impact of AR

Decision-makers need to see one thing above all else: a clear path to return on investment (ROI).

Fortunately, the benefits of AR aren't just abstract promises. They show up directly in the hard numbers and critical key performance indicators (KPIs) that matter on the factory floor. We're not just talking about "better efficiency"—we’re talking about connecting a specific feature, like AR-guided assembly, to a concrete outcome, like a 15% reduction in build time.

This is how AR moves from a "nice-to-have" innovation to an essential competitive tool.

Quantifying Efficiency and Productivity Gains

One of the first places you'll see AR make its mark is in operational speed and accuracy. Guided workflows take the mental load off your technicians. They no longer have to stop what they're doing to flip through a manual or track down a supervisor for clarification.

The result? Faster task completion, fewer mistakes, and a direct boost to productivity.

To prove it, you just need to measure what matters before and after implementation. The data will tell the story.

- Reduction in Assembly Time: AR overlays can guide workers step-by-step through even the most complex jobs, often cutting assembly time by 25% or more. That’s a massive jump in throughput without adding a single person to the payroll.

- Lower Machine Downtime: When a critical piece of equipment goes down, every minute counts. AR-guided maintenance and remote expert assistance can slash repair times. Our deep dive on augmented reality for maintenance shows exactly how this keeps your production lines running.

These gains aren’t just about working faster; they’re about working smarter and better. When technicians feel confident and have the right guidance, they make fewer errors—which brings us to the next major win.

Minimizing Defects and Rework Costs

Quality control is a non-negotiable part of manufacturing, but it can be a huge time sink. Even a tiny defect can snowball into costly rework, scrapped materials, or frustrating warranty claims. AR gives you a powerful way to catch these issues right at the source.

Think about it: by superimposing a perfect digital blueprint over a physical part, any mismatch or deviation becomes instantly obvious. This turns quality assurance from a manual, error-prone chore into a precise, data-backed process.

The financial impact here is immediate. Manufacturers using AR for quality checks have seen defect rates plummet—in some cases by as much as 90%. You're not just saving money on materials and wasted labor; you're protecting your brand's reputation by ensuring only top-tier products leave your facility.

Mapping AR Features to Business Outcomes in Manufacturing

The table below breaks down the direct line between specific AR features and the measurable business benefits they deliver on the factory floor.

| AR Feature | Operational Impact | Key Business Benefit |

|---|---|---|

| Step-by-Step Guided Workflows | Reduces cognitive load and eliminates guesswork during assembly or maintenance. | Increased Throughput: Faster task completion and up to 25% shorter assembly times. |

| Remote Expert Assistance | Allows senior technicians to see what a junior operator sees and guide them remotely. | Reduced Downtime: Faster troubleshooting and problem resolution without travel costs. |

| Digital Twin Overlays | Superimposes a 3D model of a finished product onto the physical object for inspection. | Lower Defect Rates: Early detection of errors, reducing rework costs by up to 90%. |

| Interactive Safety Warnings | Highlights potential hazards or no-go zones in the worker's field of view. | Improved Workplace Safety: Fewer accidents and a lower number of reported incidents. |

| Immersive Training Simulations | Lets new hires practice complex procedures in a risk-free virtual environment. | Faster Onboarding: Quicker ramp-up to proficiency and reduced training costs. |

This clear mapping makes it easy to build a rock-solid business case, showing exactly how the technology translates into tangible financial returns.

Enhancing Worker Safety and Training

Beyond pure productivity, AR helps build a safer, more competent workforce. Guided procedures can flag potential hazards in real-time, while immersive training modules let new hires get hands-on experience with complex machinery—without any of the risk.

This people-first approach also pays dividends.

- Reduced Incident Reports: By providing clear, in-context safety warnings, AR helps prevent accidents before they happen.

- Accelerated Onboarding: Studies have shown that AR-based training gets new employees up to speed far more quickly, closing skills gaps and making them productive members of the team sooner.

When you connect each AR application to a measurable KPI—from assembly time and defect rates to training speed and incident reports—the business case writes itself. It's a clear, data-driven argument showing that augmented reality in manufacturing delivers a strong and swift return on your investment.

Your Roadmap for Implementing AR

Bringing a new technology like AR into your operations can feel like a massive undertaking. But it doesn't have to be a sudden, factory-wide overhaul. The key is a smart, phased approach that turns a daunting project into a series of manageable, value-driven steps.

This roadmap is all about a deliberate journey. It will walk you through the essential stages, from kicking off a small-scale pilot to getting your entire team on board. Following a methodical process is how you manage expectations, secure buy-in from leadership, and lock in long-term success.

Start Small with a High-Impact Pilot Project

The best way to get started is to pick one, single problem that AR can solve—and solve well. Don't try to boil the ocean. Find a specific pain point where a quick win can show clear, measurable value to everyone watching.

Look for areas that are constant headaches:

- A complex assembly process that’s notorious for errors.

- A critical piece of machinery that causes frequent downtime during repairs.

- A quality inspection point that always seems to be a bottleneck.

By zeroing in on one of these areas, you create a controlled test bed for the technology. This is how you build an undeniable business case. A successful pilot gives you the hard data and the internal champions you need to justify rolling it out further.

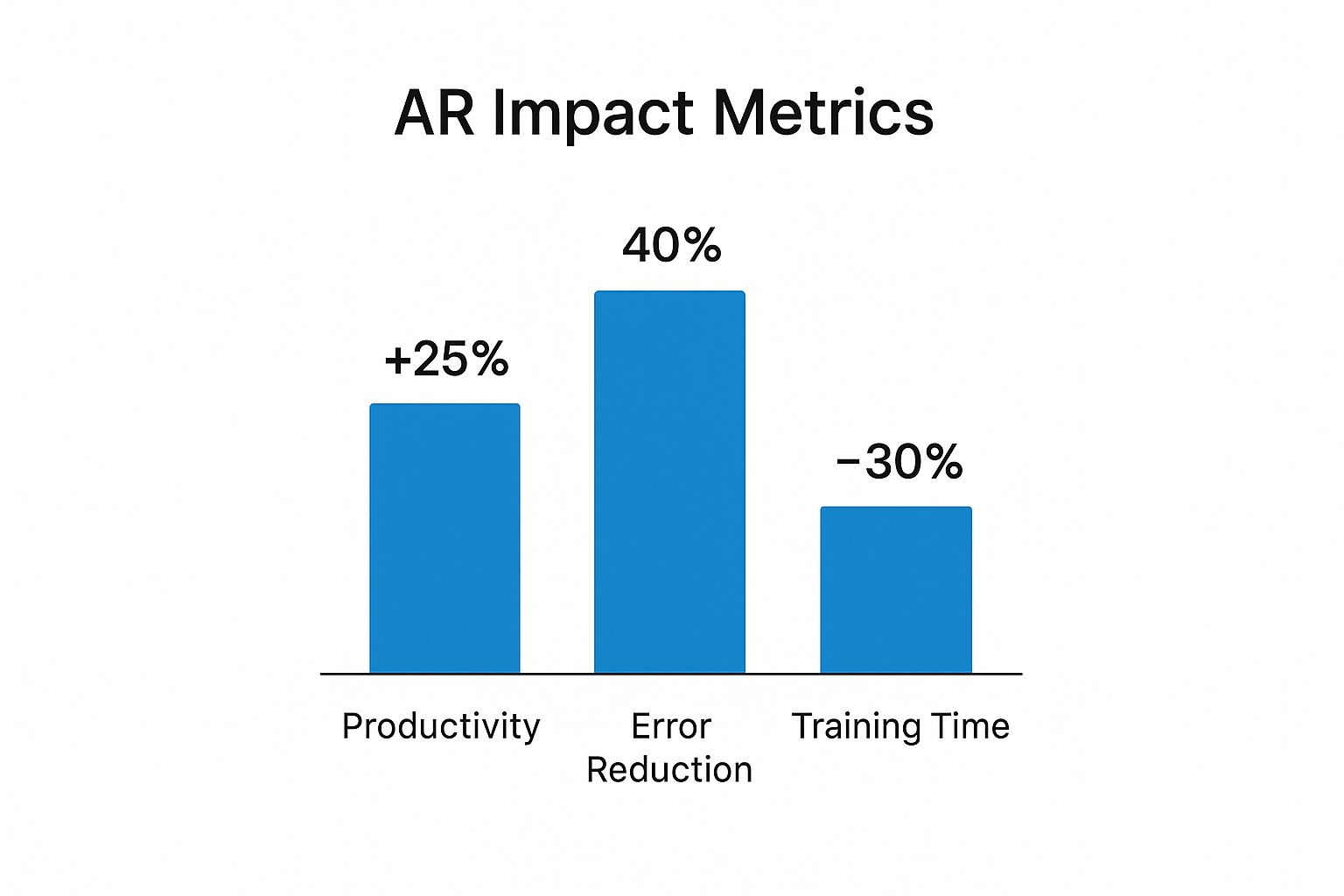

A pilot isn't just about testing tech; it's about proving business value. A well-chosen pilot can show a 25% jump in productivity or a 40% drop in errors for a specific task. Numbers like that make the case for wider adoption impossible to ignore.

Choose the Right Partners and Technology

Once your pilot project is defined, it’s time to pick the right tools for the job. The AR world is full of options, so you need to select hardware and software that actually fit your factory's reality.

Think about the environment and the task itself. Do technicians need their hands free? Rugged smart glasses are probably your best bet. Is the work focused on quality checks where a bigger screen helps? An industrial tablet might be the better call. The goal is to find flexible solutions that let you switch between different hardware without being locked into a single platform.

Your software partner is just as critical. Look for a vendor who has real-world experience in manufacturing. You need someone who offers solid support and can integrate smoothly with the systems you already rely on.

Integrate with Your Existing Systems

AR doesn't work in a silo. To really see its power, it has to talk to the systems that already run your operations, like your Manufacturing Execution System (MES) or Product Lifecycle Management (PLM) software.

This integration is what turns AR from a simple visual aid into an intelligent, data-driven tool. When AR is hooked into your MES, for example, it can pull up work instructions automatically and log when a task is finished, creating a perfect loop of information. This ensures the data your operators see is always correct and current.

A proper integration also automates the creation of AR guides by pulling information directly from your CAD models and process documents. This slashes the time and effort needed to develop and update your AR content.

The image below gives you a snapshot of the typical performance boosts companies see when they get their AR implementation right.

As you can see, the benefits are real and hit directly at operational efficiency and how quickly your team can build skills.

Train Your Workforce and Manage the Change

The final—and arguably most important—piece of the puzzle is your people. The best technology is useless if the team can't or won't use it. A successful AR rollout depends on a thoughtful approach to training and managing the transition.

Don't just hand out new gadgets and hope for the best. Build a structured training program that creates confidence and excitement. For most people, this is a whole new way of working. Using immersive tools like a virtual reality training program is a fantastic way to get employees comfortable with digital workflows in a safe space before they ever touch the real equipment.

Good change management boils down to a few key things:

- Explain the 'Why': Make it crystal clear how AR will make their jobs safer, easier, and more productive.

- Involve Them Early: Get feedback from the technicians who will use the tech every day. This ensures the solution actually works for them.

- Offer Ongoing Support: Set up a system for questions and troubleshooting as the team gets used to the new tools.

By following this roadmap, you can bring augmented reality into your manufacturing operations methodically, turning a promising technology into a real, lasting competitive advantage.

The Future of the Smart Factory Is Augmented

Augmented reality isn't just another tool in the manufacturer's toolbox. It’s quickly becoming a foundational pillar of the fully connected smart factory. The real magic happens when AR stops being an isolated solution and starts talking to other core Industry 4.0 technologies. This convergence is what builds a manufacturing ecosystem that’s more intelligent, predictive, and resilient than anything we've seen before.

Picture a factory where every machine, tool, and worker is woven into a single, cohesive digital fabric. This is the future that augmented reality for manufacturing is helping to build. It acts as the critical bridge between human and machine, translating oceans of complex data from different systems into clear, actionable guidance right on the factory floor.

The Power of a Connected Ecosystem

When you integrate AR with technologies like the Internet of Things (IoT) and Artificial Intelligence (AI), you close the loop between seeing a problem and fixing it. This creates a powerful feedback cycle that just keeps getting smarter, driving continuous improvement and operational excellence.

For instance, an IoT sensor on a robotic arm might pick up a subtle vibration—a tiny clue that a failure is on the horizon. An AI system analyzes this data, predicts a breakdown is likely within 48 hours, and automatically kicks off a predictive maintenance workflow.

This is where AR shines. The AI doesn’t just ping an alert to a dashboard. It sends a complete set of step-by-step repair instructions directly to a technician’s AR glasses. The technician arrives at the machine to find digital overlays already highlighting the exact component that needs attention, complete with animated guides walking them through the fix.

This seamless connection turns reactive, fire-fighting maintenance into proactive problem-solving. It stops downtime before it ever happens. As we see the potential of AR, it's worth looking at how other advanced manufacturing trends, like automation in packaging, are also reshaping modern production.

AR and the Rise of the Digital Twin

This connected approach gets another huge boost from the concept of the digital twin—a virtual, real-time replica of a physical asset or even an entire process. By linking a digital twin with an AR interface, workers can interact with machinery and workflows in entirely new ways.

- Visualize Hidden Components: A technician can use an AR device to "see through" a machine's metal casing, viewing a live 3D model of its internal parts as they operate.

- Simulate Changes Safely: Before physically reconfiguring a production line, operators can use AR to visualize the new layout in the real space and simulate workflows to iron out any bottlenecks—all without moving a single piece of equipment.

- Monitor Real-Time Performance: Live data from IoT sensors can be displayed directly onto the physical machine through an AR overlay, giving workers an instant, at-a-glance understanding of its operational health.

This convergence of AR with AI, IoT, and digital twins is solidifying its role as a non-negotiable technology for any manufacturer serious about building a smarter, more competitive factory of the future.

Got Questions About AR in Manufacturing? We Have Answers.

Whenever you're looking at bringing in a new technology like augmented reality for manufacturing, questions are bound to come up. It's only natural. Here are some straightforward answers to the questions we hear most often from decision-makers weighing their options.

How Is AR Different from Virtual Reality?

Think of it this way: VR replaces your world, while AR adds to it.

Virtual Reality (VR) is fully immersive—it puts you inside a completely digital environment. This is fantastic for things like complex simulations or virtual walkthroughs. Augmented Reality (AR), on the other hand, overlays digital information right onto your actual surroundings. A technician can look at a real machine and see instructions, warnings, or data points floating right on top of the physical components they need to fix.

What Kind of Hardware Is Required?

Flexibility is one of the biggest wins with modern AR platforms. The days of being locked into a single, clunky device are long gone. Now, you can pick the right tool for the job.

- Smart Glasses: The go-to for hands-free work. When a technician needs both hands for assembly or repairs, these are a game-changer.

- Tablets and Smartphones: Perfect for mobile inspections or any task where a larger screen helps to see complex diagrams and data more clearly.

Is It Difficult to Create AR Content?

Not anymore. It used to be a heavy lift requiring tons of programming, but today's solutions are built for simplicity. Many platforms can now automatically generate AR work instructions straight from your existing CAD files and process documents. This automation slashes the time it takes to get AR guides created and out onto the factory floor.

The real power of AR is how it reduces the mental load on your team. By putting clear, visual instructions directly in an operator's line of sight, you eliminate the need to constantly look away and interpret confusing 2D drawings or paper manuals. This leads to fewer mistakes and much faster work.

If you're interested in how this applies to upskilling, our guide on augmented reality for training dives deep into how this technology makes learning more intuitive and sticky, giving your workforce true hands-on experience.

At AIDAR Solutions, we're experts in using AR and VR to solve real-world industrial problems, from speeding up employee training to providing instant expert support from anywhere. See how our solutions can boost your operational efficiency at https://aidarsolutions.com.

Comment(01)