Predictive Maintenance in Manufacturing Your Guide

Picture this: you get a notification that a critical machine on your factory floor is going to fail… weeks from now. That’s the core promise of predictive maintenance in manufacturing. It’s a strategy that uses data to see the future, forecasting equipment problems long before they can trigger a costly, full-blown breakdown.

This isn't just about tweaking your maintenance schedule. It's about turning a necessary expense into a powerful, proactive advantage.

How Predictive Maintenance Is Reshaping Manufacturing

For as long as factories have existed, maintenance has largely followed two playbooks. The first is reactive maintenance, or the "if it ain't broke, don't fix it" approach. You run a machine until it fails, then scramble to fix it while production grinds to a halt. It's chaotic and expensive.

The second, preventive maintenance, is a step up. This is your scheduled, calendar-based approach—like changing your car’s oil every 3,000 miles, no matter what. It’s better than waiting for a breakdown, but it often leads to unnecessary work, wasted parts, and perfectly good components being replaced too soon.

Predictive maintenance is the smarter path forward. It’s less like a rigid schedule and more like your car’s advanced computer, which monitors everything from engine performance to oil quality to tell you exactly when service is needed. By analyzing real-time data, it stops tiny issues from snowballing into production-stopping disasters.

Before we dive deeper, let's compare these approaches side-by-side.

Comparing Maintenance Strategies

| Maintenance Strategy | Trigger for Action | Cost Impact | Operational Efficiency |

|---|---|---|---|

| Reactive | Equipment Failure | High (unplanned downtime, emergency repairs) | Very Low (unpredictable, disruptive) |

| Preventive | Fixed Schedule (Time/Usage) | Medium (unnecessary labor and parts) | Moderate (reduces failures but not optimized) |

| Predictive | Data-Driven Forecast | Low (planned repairs, optimized resources) | Very High (minimal disruption, maximum uptime) |

As you can see, shifting from a reactive or even a preventive model to a predictive one isn't just an incremental improvement—it fundamentally changes the game.

From Reactive Firefighting to Proactive Planning

The old run-to-failure model is a relic. In any modern factory, a single unexpected shutdown can create a domino effect, cascading into delays and massive financial losses.

Predictive maintenance completely flips that script. It uses sensors to listen to the heartbeat of your machinery, constantly monitoring things like vibration, temperature, and electrical currents. By analyzing this stream of data, it picks up on the subtle warning signs of an impending failure.

This foresight allows teams to schedule repairs during planned downtime, turning a potential crisis into a routine task. The results are immediate and tangible:

- Drastically reduced unplanned downtime: By catching problems early, you keep the production lines humming.

- Optimized resource allocation: Maintenance crews are deployed where and when they’re actually needed, not just because the calendar says so.

- Lower spare parts inventory: You can stock parts based on what you know you’ll need, slashing carrying costs.

This shift toward data-informed decisions is a cornerstone of the broader innovation in the manufacturing industry, helping create more resilient and profitable operations.

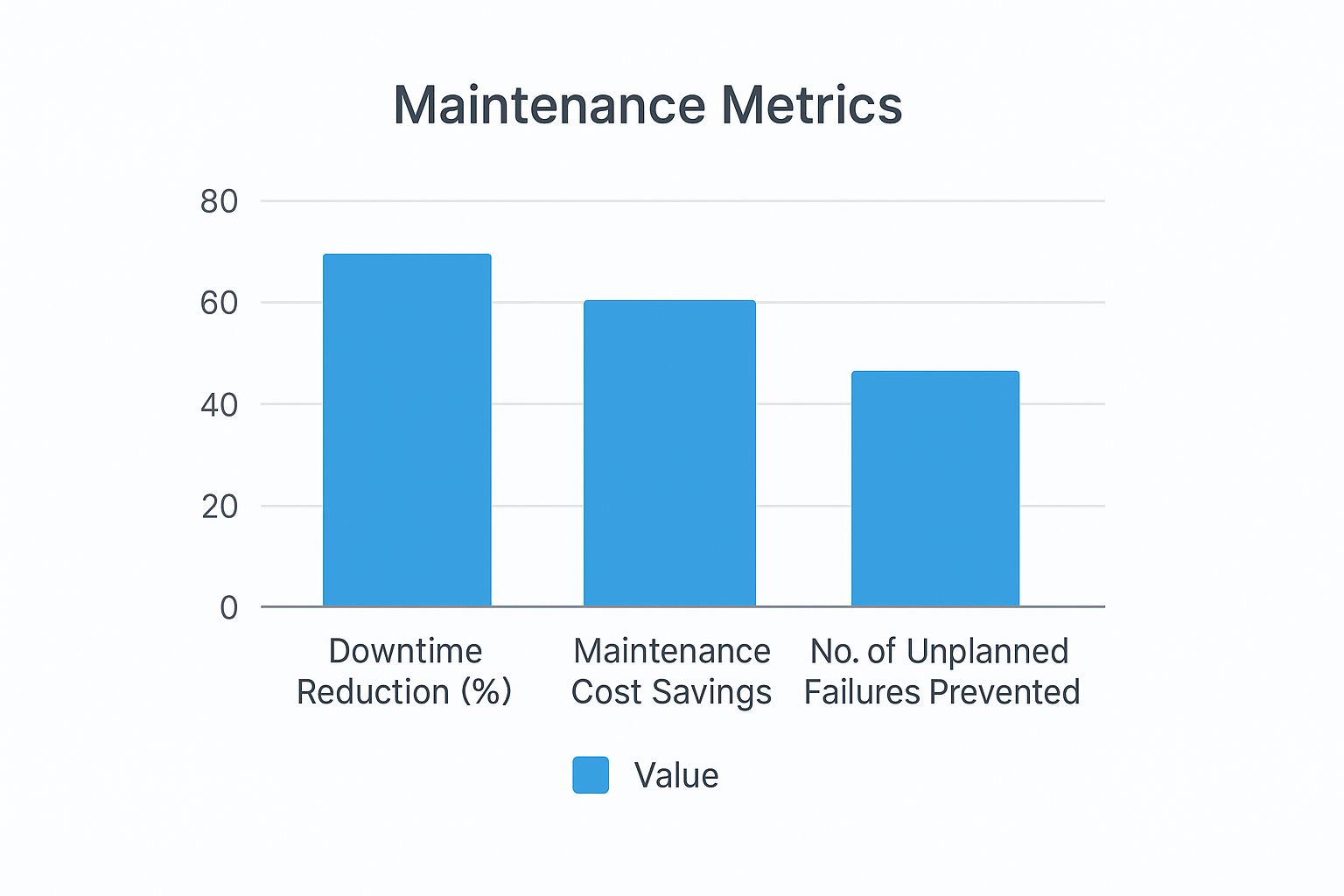

The real-world gains speak for themselves.

As the data clearly shows, adopting a predictive strategy directly leads to major reductions in downtime and failures, unlocking significant cost savings along the way.

It's no surprise that the market is exploding. The global predictive maintenance market was valued at around USD 12.7 billion in 2024 and is on track to hit an incredible USD 80.6 billion by 2033. This massive growth is a testament to how essential this technology has become for building the smart factories of the future.

The Technologies Behind Predictive Intelligence

Predictive maintenance isn’t some black-box magic; it’s a sophisticated ecosystem of connected technologies working in perfect harmony. Think of it as giving your factory a central nervous system, a brain, and the ability to act on what it knows. Each piece of this puzzle plays a specific, vital role in turning raw operational data into genuine foresight.

This powerful combination of tools pulls back the curtain, making it possible to see what’s coming down the line and plan for it. Once you understand these core technologies, you’ll see how prediction becomes a reliable part of your manufacturing strategy.

The Nervous System: IoT Sensors

It all starts with the ability to "feel" what's happening with the machinery. This is the job of Internet of Things (IoT) sensors. These small but mighty devices are the digital nervous system of the factory floor, constantly collecting data on an asset’s health.

They come in all shapes and sizes, each designed to monitor a specific condition:

- Vibration Sensors: These catch subtle changes in movement that can signal bearing wear, misalignment, or imbalance in rotating equipment like motors and pumps.

- Thermal Sensors: By tracking temperature, these sensors can spot overheating components, electrical faults, or lubrication problems long before they become critical.

- Acoustic Sensors: These devices "listen" for ultrasonic frequencies that are inaudible to the human ear, identifying things like gas leaks or internal mechanical friction.

- Pressure Sensors: Crucial for hydraulic and pneumatic systems, they flag potential blockages or leaks that could lead to a total system failure.

This constant stream of data provides the raw ingredients needed for analysis, feeding a non-stop flow of information to the system's brain.

The Brain: AI And Machine Learning

Once the sensors collect the data, it needs to be interpreted. This is where Artificial Intelligence (AI) and Machine Learning (ML) step in, acting as the intelligent core of the entire system. These algorithms are trained to analyze massive datasets and recognize patterns that would be impossible for a human to spot.

Think of an ML model as a veteran technician who has watched a machine run for millions of hours. It learns the normal operational "heartbeat" of an asset—its typical vibration patterns, temperature ranges, and pressure levels. The moment incoming sensor data starts to drift from this established baseline, the algorithm flags it as an anomaly that points to a future problem.

By analyzing these signals, AI and ML find the subtle, hidden correlations that come before equipment failure. This is what transforms raw data into a genuine prediction, allowing teams to move from reactive repairs to proactive intervention.

The Communication Network: Cloud And Edge Computing

All this data has to be processed quickly and efficiently. That’s the job of Cloud and Edge Computing. The cloud provides a centralized, scalable platform for storing huge amounts of historical data and running complex machine learning models. To get the full picture, it helps to explore the foundational cloud computing benefits.

But sometimes, decisions need to be made in milliseconds, right there at the machine. This is where edge computing shines. It processes data locally—on or near the equipment itself—slashing latency and enabling real-time responses for critical functions.

Empowering Technicians: The AR/VR Advantage

The final piece of the puzzle is empowering technicians to act on these predictions effectively. Augmented Reality (AR) and Virtual Reality (VR) are transforming how maintenance gets done by acting as a powerful bridge between digital insights and the physical world.

With AR, a technician wearing smart glasses can look at a piece of equipment and see live sensor data, historical performance charts, or step-by-step repair instructions overlaid directly onto their view. This turns a complex repair into a guided, straightforward task. It can even connect them with a remote expert who can see what they see and provide guidance in real time, dramatically improving first-time fix rates.

VR solutions provide immersive, risk-free training environments. Technicians can practice complex repair procedures on a virtual model of a machine before ever touching the real equipment. This builds muscle memory and confidence, ensuring they are prepared for any scenario. By merging the digital and physical realms, AR and VR give technicians the tools they need to execute precise, data-driven maintenance with speed and confidence.

What's the Real Business Payoff from Predictive Maintenance?

Putting new technology in place is one thing, but seeing it actually move the needle on your business goals is something else entirely. The true magic of predictive maintenance isn't just in the tech—it's in the direct, measurable impact it has on your bottom line. Forget the theoretical benefits; let's talk about the real-world value it delivers across your entire operation.

The financial upside is becoming impossible to ignore. From 2024 to 2029, the global market for this technology is expected to explode from USD 10.6 billion to USD 47.8 billion. That kind of growth doesn't happen by accident; it's fueled by companies seeing incredible results firsthand.

Maximize Uptime and Production Output

Unplanned downtime is the silent killer of profitability. Every minute a production line sits idle, you're not just losing revenue—you're dealing with wasted labor and the risk of snarling your entire supply chain. Predictive maintenance hits this problem head-on by turning surprise failures into planned, manageable events.

Instead of a panicked scramble when a machine breaks down, your team gets an alert weeks in advance. This foresight means you can schedule maintenance during off-peak hours or planned shutdowns, keeping the production line humming. The result? A massive boost to your Overall Equipment Effectiveness (OEE) and a production schedule you can actually rely on.

Think about it: a CNC machine’s spindle bearing starts showing microscopic signs of wear. Tiny changes in vibration are picked up by the sensors, and the system flags it for replacement in three weeks. The repair gets scheduled overnight, the part is ordered just in time, and zero production hours are lost.

Extend the Lifespan of Critical Assets

Let's be honest, traditional preventive maintenance can be wasteful. It often has you replacing parts based on a calendar, not on their actual condition. That means perfectly good components get tossed out, driving up costs and creating unnecessary waste. Predictive maintenance flips this model completely by basing service on the real-world health of each asset.

By keeping an eye on the actual wear and tear, you only step in to perform maintenance when it's truly needed. This data-driven approach lets you squeeze every last drop of value and operational life out of your components. In fact, using machine learning to catch these faults early can extend a machine's service life by an impressive 30%, which is a huge win for protecting your capital investments.

This shift from "time-based" to "condition-based" maintenance isn't just about saving money on parts. It ensures your equipment runs at its best for longer, pushing back those huge, costly replacement projects.

Foster a Safer Work Environment

Equipment failures aren't just expensive; they can be downright dangerous. A sudden mechanical breakdown, like a ruptured hydraulic line or a catastrophic motor failure, puts your people on the factory floor at serious risk. Predictive maintenance acts as a powerful safety net.

By flagging potential hazards before they can escalate, you can address them in a controlled, safe environment. Catching a deteriorating electrical component before it arcs or a pressure vessel before it fails helps prevent accidents, injuries, and the heavy fines that can follow. This proactive stance on safety builds a culture of prevention and protects your most valuable asset: your people.

Optimize Resources and Reduce Waste

Finally, predictive maintenance brings a new level of intelligence to managing your resources. It takes the guesswork out of scheduling maintenance crews and managing your spare parts inventory. Your technicians are sent exactly where they're needed, when they're needed, and they arrive with the right tools and information to get the job done right the first time. This also puts a huge dent in expensive overtime pay for emergency repairs.

Your inventory management gets a whole lot smarter, too. Instead of stockpiling expensive components "just in case," you can run a much leaner inventory based on accurate failure predictions. This minimizes carrying costs, cuts down on waste from obsolete parts, and streamlines your whole procurement process. Knowing how to pull these levers is crucial, as we cover in our guide on how to reduce operational costs. By optimizing both labor and materials, you unlock major savings and make your entire operation more efficient.

How Top Manufacturers Use Predictive Maintenance

Knowing the theory behind predictive maintenance is one thing, but seeing it in action on the factory floor is where it all clicks. The best manufacturers aren't just tossing around a buzzword; they're embedding this strategy into their core operations to tackle expensive, nagging problems. From automotive giants to food processors, these practical applications are making factories smarter, safer, and a whole lot more productive.

These real-world examples show how predictive maintenance moves from a concept on a slide deck to a source of real, measurable value. By wiring up critical assets with sensors and smart analytics, companies can finally get ahead of failures that once seemed totally random. This foresight is what turns maintenance from a reactive firefight into a planned, strategic advantage.

Preventing Assembly Line Catastrophes in Automotive

Picture a massive automotive plant, where robotic arms are humming along 24/7. A single unplanned stop on that assembly line can hemorrhage millions in lost production. In this kind of high-stakes world, even a tiny motor failing in one robot can bring the entire operation to a screeching halt. This is exactly where predictive maintenance in manufacturing shines.

Engineers attach vibration sensors to the joints and motors of each robotic arm. These little devices are constantly listening for microscopic changes in movement and sound that give away motor fatigue or bearing wear long before a human could notice. That data streams into a machine learning model that knows the unique operational "fingerprint" of every single robot.

When the algorithm spots a deviation from that normal pattern, it flags it for the maintenance team—often weeks before the failure is expected to happen. This gives them a massive heads-up to schedule a replacement during a planned weekend shutdown, completely side-stepping a costly production halt. This proactive approach has been shown to save hundreds of thousands of hours of downtime in large-scale automotive operations.

Safeguarding Quality in Food and Beverage Processing

Now, let's switch gears and walk into a food processing facility. Here, huge industrial cookers have to maintain incredibly precise temperatures. If a heating element gives out unexpectedly, it can ruin an entire batch of product. We're talking major material waste and even the risk of a product recall. Here, consistency is everything.

Thermal sensors inside these cookers are always monitoring how each heating element is performing. The system chews through that thermal data, hunting for any inconsistencies or signs that an element is struggling to hold its temperature. That slight dip in performance is the canary in the coal mine for an impending failure.

By flagging a weakening component before it actually breaks, the system lets the maintenance team swoop in for a targeted repair. This doesn't just prevent spoiled food; it ensures the plant keeps hitting its high standards for quality and safety, protecting both its revenue and its reputation.

Empowering Technicians with Augmented Reality

Getting a heads-up about a failure is only half the battle. The best manufacturers are also rethinking how the actual repairs get done. This is where immersive tech like Augmented Reality (AR) provides a huge leap in efficiency.

Imagine a new technician is sent to fix a complex piece of equipment that the predictive system flagged. Instead of getting bogged down in a thick paper manual, she puts on a pair of AR smart glasses. Looking at the machine, she sees a 3D digital overlay of its components, with the exact part needing replacement highlighted in red. Step-by-step instructions pop up right in her field of view, walking her through the whole fix.

If she hits a snag, she can start a remote assistance call. A senior expert miles away can see exactly what she sees through her glasses and give real-time advice, even drawing digital arrows that "stick" to the physical machine to point things out. This approach marries predictive insights with powerful tools for getting the job done right. You can dive deeper into how companies are using augmented reality for maintenance to see just how much this tech is changing fieldwork. It’s a game-changer that slashes repair times, cuts travel costs for experts, and gives frontline workers the confidence and knowledge they need to handle anything.

Navigating the Roadblocks to Implementation

Switching to a predictive maintenance program is a game-changer, but let's be real—it's not a walk in the park. Moving from a traditional, "if it ain't broke, don't fix it" mindset to a proactive, data-first strategy means you're going to hit a few bumps in the road. Knowing what these are ahead of time is the secret to a smooth rollout.

The path to predictive intelligence is all about getting your data, tech, people, and processes in sync. If you see these challenges coming, you can build a strategy that’s tough enough to handle the initial friction and deliver real value for years to come.

Wrangling Your Data and Systems

One of the first—and biggest—headaches is the data itself. Most facilities are a mashup of brand-new and old-school equipment. Those older machines? They weren't built with modern sensors, so getting good, clean data from this mix can feel like a huge obstacle.

The most common fix is retrofitting your legacy assets with new IoT sensors. This simple step bridges the technology gap, letting you pull vital operational data like vibration and temperature from even your oldest, most reliable workhorses. The next move is to plug that new data stream into your existing systems, like a CMMS or ERP, so the predictive insights flow right into your team's daily workflow.

A lot of people think they need perfect data to even start. The truth is, you can begin with the data you already have from a few critical assets. That's often enough to build an initial model, show some early wins, and build momentum for a bigger data governance plan.

Making the Case for the Upfront Cost

Another major hurdle is the initial investment. The price tag for sensors, software, and getting it all set up can look steep. The key to getting the green light from stakeholders is to frame it as a long-term investment, not just another expense.

Don't just focus on the upfront cost. Build a rock-solid business case around the Return on Investment (ROI). Show them the money you'll save by slashing unplanned downtime, carrying fewer spare parts, and making your equipment last longer. A great way to do this is to start small with a pilot program on a single, high-impact asset. You can prove the concept and show real returns fast, which makes it a whole lot easier to justify a full-scale rollout.

The global trend is already proving the value. Take Europe—it’s a huge player in the predictive maintenance market and is expected to pull in over 30% of global revenue in 2025, which comes out to around USD 3.37 billion. That kind of strong adoption, fueled by industrial modernization, shows the clear financial upside organizations are seeing. You can dig into the data on market growth to help build your own case. Learn more about these global market trends from Cognitive Market Research.

Closing the Skills Gap

Predictive maintenance is all about data, and that can create a skills gap on your team. Your maintenance techs are mechanical wizards, but they probably aren't data scientists. This is a super common challenge, and it's totally solvable with a commitment to training.

To get your team up to speed, focus on targeted training that gives them the right tools:

- Data Literacy: Teach technicians how to read the dashboards and actually understand what the insights are telling them.

- New Tech Training: Get them hands-on with any new tools, whether it’s AR headsets for guided repairs or new software.

- Cross-Functional Teamwork: Get your IT, data science, and maintenance crews talking to each other. Fostering that partnership ensures everyone is speaking the same language.

Remember, investing in your people is every bit as important as investing in the technology.

Your First Steps Toward a Predictive Strategy

Jumping into a full-blown predictive maintenance strategy can feel like trying to boil the ocean. But here’s the secret: the best approach isn’t to go big, it’s to start smart. A focused, well-planned pilot project is the absolute best way to show value quickly and build the kind of momentum you need for a company-wide program.

This method takes the risk out of the investment and teaches you invaluable lessons that will shape your broader rollout. By following a clear, step-by-step process, you can build a solid foundation for long-term success.

Start Small With a Pilot Project

First things first: resist the temptation to overhaul your entire operation at once. Instead, zero in on a single, high-impact asset to kick off a pilot program. This machine should be critical—one where even a small reduction in downtime creates a clear win everyone can see.

Rotating equipment like pumps, motors, and fans are often perfect candidates. Why? Because their failure patterns are generally well-understood and can be monitored easily with simple vibration sensors.

By focusing on one piece of equipment, you create a controlled sandbox to test your tech, your processes, and your team. This initial project becomes your proof of concept, spitting out the hard data you need to build a rock-solid business case for more investment. It’s all about proving the value of predictive maintenance in manufacturing on a small scale before you aim for the big leagues.

Define Clear and Measurable Goals

Before you even think about attaching a sensor, you need to define what victory looks like. Vague goals like "improve efficiency" just won't cut it. Your objectives have to be specific, measurable, and tied directly to real business outcomes.

The most successful pilot programs begin with a clear problem to solve. Instead of just implementing technology for its own sake, pinpoint a specific pain point and aim your efforts there.

For instance, a great goal sounds like this: "Reduce unplanned downtime on CNC Machine #7 by 15% within six months." This gives your team a finish line to run toward and gives you a concrete metric to measure your return on investment. Other solid goals could be extending the asset's maintenance cycle or cutting down on spare parts consumption for that one machine.

Choose the Right Tech Without Overinvesting

With your target asset and goals locked in, it's time to pick your tools. For a pilot, you don't need a massive, enterprise-wide platform. Focus on a solution that solves the specific problem for your chosen asset.

This might be as simple as a few vibration and temperature sensors hooked up to a straightforward, cloud-based analytics dashboard. The aim here is to gather meaningful data and get accurate predictions without getting tangled up in a complex implementation. This lean approach keeps your initial costs low and gets you to a positive ROI faster, making it much easier to get buy-in for the next phase.

To help guide your efforts, here is a straightforward checklist for launching your pilot program.

Predictive Maintenance Implementation Checklist

| Phase | Key Action | Success Metric |

|---|---|---|

| 1. Planning & Scoping | Identify a critical asset with a history of costly failures. | Asset selected and historical downtime data collected. |

| 2. Goal Setting | Define a specific, measurable goal (e.g., reduce downtime by X%). | A clear, documented KPI is established and agreed upon. |

| 3. Technology Selection | Choose sensors and software tailored to the pilot asset. | Vendor selected and hardware ordered within budget. |

| 4. Implementation | Install sensors and configure the monitoring platform. | System is live and collecting data successfully. |

| 5. Data Collection | Run the system for a set period (e.g., 90 days) to build a baseline. | Stable data stream with minimal connectivity issues. |

| 6. Analysis & Action | Monitor alerts, analyze data patterns, and schedule interventions. | At least one potential failure is predicted and averted. |

| 7. Reporting & ROI | Compare pilot results against the initial goal and calculate ROI. | A final report demonstrating positive ROI is presented. |

| 8. Scale-Up Strategy | Use pilot learnings to develop a plan for a broader rollout. | A phased expansion plan is approved by stakeholders. |

Following these steps provides a structured path from a small, manageable test to a full-scale, value-driving predictive maintenance program.

Frequently Asked Questions

Jumping into predictive maintenance usually brings up a few practical questions. We've gathered the most common ones we hear from manufacturers considering this shift, with straightforward answers to help you get started.

How Much Does a Predictive Maintenance Program Cost?

There's no single price tag here—the cost really hinges on your specific needs and how big you want to go. A few key factors will shape your initial investment and ongoing expenses.

Think of it in terms of these core components:

- Hardware: This is all about the sensors (like vibration or thermal sensors), which can run anywhere from a few hundred to a couple of thousand dollars for each piece of equipment you're monitoring.

- Software and Platforms: The brains of the operation. Licensing for analytics software is a big part of the budget, and costs will scale with the complexity and number of machines you're tracking.

- Implementation and Integration: Getting the new system talking to your existing CMMS or ERP platforms is a job for the experts.

- Training: You'll need to get your team up to speed on interpreting the new data and using the tools. It’s a critical investment.

For a small pilot project focused on a handful of critical assets, you might be looking at $50,000 to $200,000. A full, enterprise-wide rollout? That can easily climb past $1 million. But remember, this is an investment you weigh against the crippling cost of unplanned downtime.

Can This Work on My Older Equipment?

Absolutely. This is one of the biggest myths about predictive maintenance in manufacturing—that it’s only for shiny, new, smart-factory machines. The truth is, your trusty legacy equipment can be the perfect candidate.

The magic word is retrofitting. By installing modern IoT sensors on your older assets, you can bring them right into your digital ecosystem. These sensors become the eyes and ears, collecting the vital operational data you need for analysis. It’s a brilliant way to extend the productive life of reliable old workhorses while still getting all the benefits of modern predictive insights.

What Is the Very First Step My Company Should Take?

Start small. Prove the value. Forget about a massive, facility-wide overhaul right out of the gate. Instead, pick one critical business problem you can solve with a focused pilot project.

Ask yourself this: "Which machine failure causes us the most pain?" Zero in on an asset where unexpected downtime is especially costly or disruptive. That’s your pilot target.

By channeling your initial efforts into solving one high-impact problem, you create a clear and direct path to showing a real return on investment. That success story is what builds momentum and gets the buy-in you need to scale your predictive maintenance strategy across the rest of your operations.

Ready to see how AR and VR can supercharge your maintenance and training programs? AIDAR Solutions provides immersive tools that reduce downtime, slash travel costs, and empower your technicians. Discover our solutions today.