A Practical Guide to Maintenance Augmented Reality

When a technician needs to service a complex piece of machinery, the traditional process often begins with searching for a physical manual, deciphering dense schematics, or contacting a senior expert who may be miles away. This approach can be slow, inefficient, and susceptible to human error. A more effective solution is now available.

Maintenance augmented reality transforms this dynamic. It provides a digital expert standing beside the technician, projecting instructions, 3D models, and real-time data directly onto the equipment being serviced. This is a practical tool that bridges the gap between digital information and the physical world, enhancing operational efficiency.

Unlocking Efficiency with Maintenance Augmented Reality

Consider a field technician facing an unfamiliar industrial pump. Instead of referencing a tablet or laptop, they are wearing smart glasses. Through the lenses, animated arrows highlight the exact bolts to unscrew, and a step-by-step guide appears in their line of sight. This is the power of maintenance augmented reality in action.

The technology utilizes hardware—such as smart glasses or a standard smartphone—to view the real-world environment. Specialized software then intelligently overlays relevant digital information onto that view, creating an intuitive, interactive guide that empowers technicians of any skill level.

The Key Components at Work

At its core, the technology combines two critical elements:

- Hardware: This serves as the window to the blended physical-digital environment. It can range from specialized smart glasses for hands-free operation to the tablets and phones your team already uses.

- Software: This is the core intelligence of the system. A powerful platform processes the hardware's visual input and projects the correct information—whether it's a 3D model, sensor data, or a guided workflow.

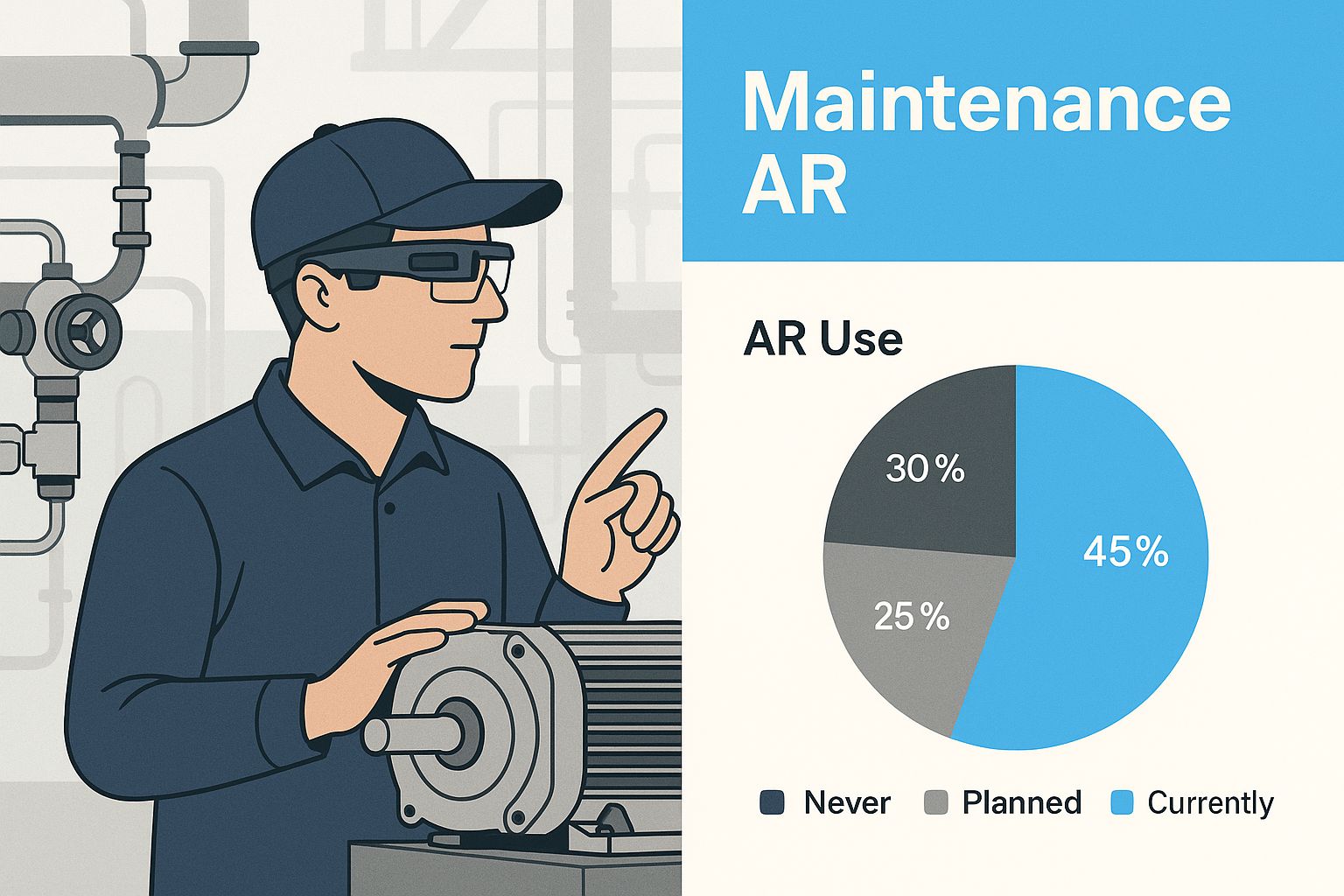

The image below illustrates a common application: a technician using smart glasses to get a closer look at a machine, hands-free.

This hands-free capability is a significant advantage. It allows technicians to keep their tools in their hands while receiving all the critical information required to perform the job correctly.

To understand the impact of this approach, let's compare it to traditional methods.

Traditional vs. AR-Powered Maintenance: A Comparison

This table outlines the core differences, highlighting how AR modernizes maintenance operations.

| Maintenance Aspect | Traditional Method | AR-Powered Method |

|---|---|---|

| Information Access | Relies on paper manuals, PDFs, or remote calls. Often slow and cumbersome. | Instant, on-demand visual guides and data overlays directly in the field of view. |

| Expert Guidance | Requires a senior expert to travel to the site or provide phone support. | "See-what-I-see" remote assistance allows experts to guide technicians from anywhere. |

| Error Rate | Higher potential for mistakes due to misinterpreting complex diagrams or instructions. | Step-by-step visual instructions drastically reduce human error and rework. |

| Training Time | Lengthy onboarding and shadowing required for new technicians. | New hires become proficient faster by following interactive, on-the-job training guides. |

| Downtime | Longer repair times due to searching for information and waiting for support. | Faster problem diagnosis and resolution lead to significant reductions in equipment downtime. |

The contrast is clear. AR doesn't just incrementally improve speed; it fundamentally transforms the entire workflow for greater efficiency and accuracy.

A Rapidly Growing Market

It is no surprise that AR adoption is expanding rapidly across industries. The global AR market is already valued at over USD 207.16 billion and is projected to reach nearly USD 2.8 trillion by 2034, growing at an annual rate of 38.5%.

The hardware component, particularly head-mounted displays used by technicians, already constitutes more than 58% of the global market share. This indicates a significant shift towards integrating this technology into modern industrial operations.

By removing ambiguity from complex tasks and delivering information precisely where it is needed, AR makes maintenance safer, faster, and more reliable. This is one of many applications; for a broader perspective on how augmented reality for industry is reshaping industrial processes, further reading is available.

The Core Features Driving AR Maintenance

Augmented reality’s effectiveness in maintenance is not derived from a single function but from a combination of practical features that solve real-world problems. It acts as a digital toolkit, providing technicians with the necessary information at the right time. This transforms a complex repair into a clear, guided process.

This synergy of features is supported by a growing hardware market. The demand for immersive industrial solutions has driven significant expansion in the AR and VR hardware sector. For maintenance crews, this growth is a major benefit. Hands-free, voice-controlled AR devices mean technicians can access schematics or consult an expert without putting down their tools or handling a bulky manual.

Remote Expert Assistance

Imagine a junior technician encountering a critical equipment failure for the first time. Traditionally, this would involve waiting hours—or even days—for a senior expert to travel to the site.

With AR, the technician can wear smart glasses and share their exact point-of-view in a live video feed. A remote expert sees what the on-site technician sees and can provide immediate, over-the-shoulder guidance. The expert can draw annotations that appear locked onto the machine, highlight specific components, or push technical documents directly into the technician's field of view. This transforms a high-stress solo task into a collaborative, on-the-job training session, significantly reducing downtime and travel costs.

Digital Work Instructions

Paper manuals and static PDFs are becoming obsolete. With maintenance augmented reality, technicians receive step-by-step instructions and animated 3D models overlaid directly onto the machinery they are servicing.

For example, when tackling a complex assembly, the AR system can highlight the exact part needed, show its correct orientation, and visually guide the technician through the entire sequence. This visual, in-context guidance practically eliminates human error and ensures procedures are followed with precision every time. To maximize these benefits, it is crucial to establish a well-defined augmented reality workflow.

These digital guides do more than improve accuracy; they empower technicians to confidently handle tasks that were previously outside their immediate expertise, which accelerates repairs and improves first-time fix rates.

IoT Data Visualization and Reporting

Modern equipment is equipped with sensors that generate a continuous stream of data. AR provides the means to make this data actionable by pulling live information from IoT sensors—such as temperature, pressure, or vibration levels—and displaying it directly on the physical asset.

A technician can look at a motor and see its current operating temperature displayed above it. This makes diagnostics instantaneous, eliminating the need to consult a separate monitor or control panel. Furthermore, many systems now support hands-free digital reporting. Using voice commands, a technician can capture photos of the completed work, record video notes, and automatically log the work order as complete. This ensures that all critical data is captured accurately and efficiently at the point of service.

How AR Delivers Measurable Business Results

The adoption of any new technology is ultimately judged by its return on investment (ROI). For maintenance augmented reality, the benefits are not abstract concepts but clear, measurable improvements to key business metrics. AR delivers tangible financial gains by making maintenance faster, safer, and more accurate.

For instance, remote expert assistance immediately reduces the significant costs associated with travel. What previously required a multi-day delay for an expert to arrive on-site becomes an efficient video call. Similarly, digital work instructions empower less experienced technicians to handle complex jobs correctly on the first attempt, reducing the workload on senior team members.

Improving Your Operational KPIs

The true impact of AR becomes evident when analyzing key performance indicators (KPIs). The technology drives substantial improvements in the metrics that define operational success.

- Reduce Equipment Downtime: By providing technicians with instant access to schematics and expert support in their line of sight, AR helps them diagnose and resolve problems more quickly. Reduced support delays translate directly to increased uptime for critical assets.

- Boost First-Time Fix Rates: AR acts as a digital co-pilot, guiding technicians through procedures with visual, step-by-step instructions. This approach dramatically reduces human error, leading to fewer repeat visits and minimizing wasted time and resources.

Case studies from manufacturing and utilities show that AR helps maintenance technicians perform tasks with a 40–50% reduction in error rates and up to 30% faster completion times. Global companies report that AR-driven maintenance has reduced their costs by an average of 12% and boosted first-time fix rates by 17%.

A Safer, More Cost-Effective Workplace

Beyond speed and accuracy, maintenance AR contributes to a safer work environment. Technicians using smart glasses can operate completely hands-free, maintaining focus on the task while keeping their tools in hand. This enhances situational awareness, particularly when working around heavy machinery.

AR can also proactively prevent accidents. For example, digital warnings can be overlaid directly onto equipment, highlighting a high-temperature surface or a high-voltage area. This makes safety information immediately visible.

Ultimately, these benefits lead to lower overall expenses. Faster repairs, fewer errors, eliminated travel for experts, and a safer workforce all contribute to a significant reduction in operational spending. For a deeper analysis, review our guide on how to reduce operational costs. Implementing maintenance AR is not just a technological upgrade; it is a strategic investment with a clear financial return.

Where AR Shines: Real-World Use Cases Across Industries

While the theory is compelling, observing maintenance augmented reality in practical applications demonstrates its true value. AR's flexibility allows it to address a wide range of industrial challenges, transforming complex, high-stakes jobs into manageable, step-by-step procedures. The technology adapts to the unique requirements of each sector, delivering measurable results where they matter most.

From a fast-paced factory floor to a remote energy substation, AR overlays a crucial layer of digital intelligence onto a technician's real-world view. This hands-on, in-the-moment support is revolutionizing field service and industrial maintenance.

Maintaining Manufacturing Lines

On a manufacturing floor, every second of downtime translates to lost revenue. Consider a line operator performing a complex machine changeover. Instead of consulting a manual or a terminal, they can wear AR glasses.

3D instructions are projected directly onto the machine, highlighting the exact levers to pull and displaying precise torque settings for each bolt. This guided process significantly reduces changeover times and minimizes the risk of errors that could cause a major shutdown. The potential applications are extensive; you can explore these augmented reality industrial applications to understand the broader impact.

Enhancing Safety in Energy and Utilities

Technicians in the energy sector often work in challenging, remote, and sometimes hazardous environments. An AR device can assist a technician inspecting a wind turbine hundreds of feet in the air by displaying live IoT sensor data and real-time performance metrics overlaid directly on the physical components.

If an unexpected issue arises, they can instantly initiate a remote expert call. A senior engineer, located safely in a central office, can see exactly what the field technician sees and guide them through the repair. This ensures the work is done correctly—and safely—the first time.

By providing technicians with hands-free access to critical data and expert assistance on demand, AR dramatically improves worker safety while enhancing the reliability of critical infrastructure.

Ensuring Compliance in Aerospace

The aerospace industry operates under the highest standards of safety and compliance, where there is no margin for error. An aviation engineer inspecting an aircraft engine can use an AR-powered checklist that visually guides them through hundreds of inspection points.

As they move around the engine, the AR system automatically recognizes each component and presents the relevant inspection criteria. This not only accelerates the process but also creates a complete and unalterable digital record. This simplifies audit trails and guarantees full compliance with the industry's stringent safety protocols. This on-the-spot guidance is part of a larger trend where new technologies, such as solar panel inspection drones for maintenance efficiency, are being utilized to enhance performance in specific industrial settings.

Your Roadmap to an Effective AR Program

Once you have decided to implement maintenance augmented reality, the next step is to move from concept to a full-scale program that your team will use and benefit from.

A successful rollout avoids the "big bang" approach. It involves taking calculated steps, building momentum, and proving value along the way. This roadmap will help you navigate the process and integrate AR into your maintenance operations effectively.

Start with a Focused Pilot Project

Before considering an enterprise-wide deployment, a focused success is essential. The best way to achieve this is to select a single, high-impact problem and apply AR to solve it.

Identify a piece of machinery that frequently causes issues or a complex procedure that only a few senior technicians have mastered. This will be your pilot project. By narrowing your focus, you create an ideal environment to test the technology and measure key metrics: repair times, first-time fix rates, and technician feedback. A successful pilot provides the hard data and success story needed to gain broader organizational support.

Proving a clear return on investment (ROI) with a small, targeted project is the single most effective way to get buy-in from leadership for a larger AR initiative.

Select the Right Tools for the Job

Next, you must select your equipment. This decision should be driven entirely by the actual tasks your technicians perform daily. Focus on practical solutions for your team.

-

The Hardware: You have several options. For initial pilots or tasks where technicians have a free hand, tablets and smartphones are a low-cost starting point. For complex, hands-on repairs, industrial-grade smart glasses are ideal. They allow technicians to keep their hands on their tools and their focus on the task.

-

The Software: Look for a platform that integrates with your existing systems, particularly your CMMS. The solution should be user-friendly for your team. Essential features include live remote expert support, an intuitive tool for building and following digital work instructions, and robust reporting to track your progress.

Digitize Your Team’s Knowledge

The most advanced AR hardware is ineffective without quality content. This step involves converting institutional knowledge, currently stored in binders and with senior technicians, into interactive AR guides.

Begin by digitizing existing materials: paper manuals, schematics, and standard operating procedures (SOPs). Once you have a digital foundation, you can start building interactive workflows. Break down complex repair jobs into simple, visual, step-by-step instructions. Enhance them with 3D models, short video clips, and annotated photos to ensure clarity.

Ensure Team Adoption with Training and Feedback

The final element is your team. The technology can be perfect, but without user adoption, the project will fail. Implement a comprehensive training program that not only explains how to use the tool but also why it makes their jobs easier and safer.

Crucially, establish a feedback loop. Ask your technicians what is working, what is not, and what they need. By incorporating their feedback, you not only improve the system but also demonstrate that you value their expertise. This turns your team from users into advocates, ensuring the long-term success of your AR program.

The Future of Intelligent Maintenance with AR

Augmented reality for maintenance is more than a solution for today's challenges; it is a foundational technology for the future of industrial work. Its true potential is realized when integrated with other smart technologies, creating an ecosystem that anticipates problems before they occur. This represents a significant shift from the reactive "break-fix" model toward a more proactive and intelligent approach.

The most transformative integration is with Artificial Intelligence (AI). When AI algorithms are incorporated into an AR system, it can analyze real-time data from equipment sensors to predict failures. For example, a technician could point a tablet at a motor and receive an AR alert: "Vibration patterns indicate a 72% probability of bearing failure within the next 72 hours." This is true predictive maintenance, enabling a scheduled repair instead of an emergency shutdown.

Digital Twins: The Virtual Proving Ground

Another component of this future is the Digital Twin—a precise virtual replica of a physical machine, continuously updated with live data from its real-world counterpart.

For maintenance crews, this provides a risk-free training and simulation environment for every critical asset. Before a technician services the actual multi-million-dollar equipment, they can:

- Perform the entire repair procedure on its digital twin using a headset.

- Simulate various failure scenarios to improve troubleshooting skills.

- Validate a repair plan without taking the physical machine offline.

This combination of AR, AI, and digital twins represents the next generation of intelligent maintenance. It is the same powerful synergy driving innovation in other fields, as discussed in this article on how AI and automation are revolutionizing drone operations.

In this new paradigm, AR becomes the essential human interface for the Industrial Internet of Things (IIoT). It translates vast streams of machine data into simple, actionable visuals directly in the worker's field of view.

Ultimately, integrating AR into your maintenance workflow is a strategic move to build more resilient, efficient, and forward-thinking operations prepared for future industrial innovations.

Common Questions About AR in Maintenance

Adopting any new technology raises practical questions. When it comes to augmented reality for maintenance, most teams have similar inquiries: What equipment is needed? Will it integrate with our existing software? How long does it take for technicians to become proficient?

Let's address these common questions. The implementation process is often simpler than anticipated, especially with a well-structured plan.

What Hardware Do I Need to Start?

You can begin with the devices your technicians already use. Smartphones and tablets are ideal for launching a pilot program without a significant upfront investment. They are effective for testing digital work instructions or conducting initial remote support calls.

Once the value has been demonstrated on high-impact tasks, you can scale up to industrial smart glasses for hands-free operations. A prudent approach is to prove the concept with mobile devices first, then expand when the ROI is clear.

Can AR Integrate with Our Current CMMS?

Yes. Modern AR platforms are designed to connect with the tools you already use. Leading solutions use APIs (Application Programming Interfaces) to link directly with your Computerized Maintenance Management System (CMMS) and other essential enterprise software.

This creates a seamless flow of information. You can pull work orders, asset data, and maintenance histories directly into the AR interface, providing your technicians with a single source of truth for every job. This eliminates the need to switch between devices or search through records.

How Much Training Will My Technicians Need?

A significant advantage of AR is its visual and intuitive nature, which results in a very short learning curve. Most technicians can master the core functions—such as following step-by-step digital guides or contacting an expert for assistance—in a single training session.

The purpose of this technology is to simplify work, not to add another layer of complexity. User-friendliness is a core design principle of leading AR solutions, which facilitates rapid and effective adoption by teams of all skill levels.

Ready to see how AR can transform your maintenance operations? AIDAR Solutions develops immersive AR and VR applications that reduce service times, cut expert travel costs, and accelerate new hire training. It's time to discover a smarter way to work.

Learn more about what we do at AIDAR Solutions.