How to Improve First Call Resolution in Field Service

Improving first call resolution isn't just about closing tickets faster. It's about fundamentally shifting how you operate—empowering your technicians, fine-tuning your processes, and arming them with the right technology to deliver the solution on the very first visit.

The core objective is to eliminate the need for a second visit. Achieving this directly impacts customer satisfaction and slashes operational costs, turning FCR from a simple metric into a powerful engine for business growth.

Why First Call Resolution Is a Core Business Driver

First Call Resolution (FCR) is often categorized as just another support metric, but its impact runs deep, touching the financial and operational health of any industrial company. It’s a direct reflection of your team's efficiency, their expertise, and the strength of your customer relationships.

When a technician cannot resolve an issue on the first visit, the consequences extend beyond a single customer. Each repeat truck roll incurs direct costs like fuel, labor, and vehicle wear. However, the indirect costs are often more significant. Extended equipment downtime can bring a customer's production line to a halt, causing substantial revenue loss and eroding trust.

The Real Cost of a Failed First Visit

A low FCR rate is not just an operational challenge; it's a constant drain on your bottom line. Consider the resources consumed by a single repeat visit:

- Duplicated Labor Hours: You are effectively paying a technician twice to solve one problem.

- Increased Parts Consumption: An incorrect initial diagnosis often leads to wasted parts and inventory complications.

- Customer Downtime: This is a critical factor. It can cost your client thousands in lost production and cause serious damage to your reputation.

In the high-stakes environments of manufacturing and field service, a high FCR is essential. Data from the Qualtrics XM Institute indicates the global average FCR rate is 62%. The benefits of getting it right are significant. Customers who receive a first-time fix are 1.9x more likely to trust the brand and 2.1x more likely to recommend it.

To better assess your team's performance, it helps to understand industry benchmarks.

FCR Performance Benchmarks Across Industries

This table provides a clear snapshot of FCR benchmarks, showing what is considered average, good, and world-class. Use it to contextualize your own team's performance and set realistic goals.

| Performance Level | FCR Rate | Typical Industry |

|---|---|---|

| Average | 60-70% | High-volume, low-complexity support |

| Good | 70-80% | General field service, IT support |

| World-Class | 80%+ | Specialized industrial, MedTech, high-stakes manufacturing |

Achieving a world-class FCR doesn't happen by accident. It requires a dedicated strategy focused on people, processes, and technology.

Shifting From Metric to Mindset

Treating FCR as a core business driver demands a new way of thinking. It’s not about pressuring technicians to close tickets faster; it's about equipping them to solve problems with confidence and finality. That means investing in their skills, providing them with the best tools for the job, and designing processes that set them up for a first-time fix.

A high FCR rate is the clearest sign of a healthy field service operation. It demonstrates that your people, processes, and technology are all aligned to deliver value efficiently and effectively on the first attempt.

When you prioritize FCR, you empower your team to be more effective and build the kind of customer trust that creates lasting partnerships. Your service team transforms from a cost center into a value-generating asset. Understanding your key operational efficiency metrics is the first step, but a relentless focus on FCR is what builds a more resilient and profitable service operation.

Diagnosing the Root Causes of Repeat Visits

To improve a low First Call Resolution rate, you must adopt an investigative approach. Simply instructing your team to "get it right the first time" is ineffective. It does nothing to solve the real, underlying issues that necessitate repeat visits.

The path to a better FCR begins with a deep dive to pinpoint exactly why a job requires a second truck roll.

Surface-level explanations like "the technician needed a different part" are often symptoms, not the root cause. Was the initial diagnosis wrong due to a knowledge gap? Did the technician lack the correct schematic for that specific machine model? Were they unable to reach a senior expert for guidance? These are the root causes that, left unaddressed, will continue to lower your FCR, drive up costs, and result in dissatisfied customers.

Moving Beyond Surface-Level Assumptions

Consider this common scenario: a mid-level technician is dispatched to fix a custom CNC machine displaying an unfamiliar error code. After two hours of standard diagnostics, they make no progress. The machine’s manual is extensive and does not cover this particular custom modification.

They attempt to call a senior technician for advice, but the expert is occupied with another complex job. Without the necessary information and immediate support, the technician is forced to schedule a follow-up visit, leaving the client with a non-operational machine. The service log simply states, "further diagnostics required."

This single failed visit points to several potential process breakdowns:

- Knowledge Gaps: The technician lacked the specialized expertise for that unique equipment.

- Information Accessibility: The correct documentation was not available on-site.

- Expert Support Delays: The system for accessing senior expert support was slow and inefficient.

These are the hidden problems that must be brought to light. Improving your FCR means investigating these details to understand the true barriers your team faces in the field.

A Practical Framework for Uncovering Inefficiencies

To get a clear picture of the operational reality, you need to gather intelligence from multiple angles. Reviewing service logs alone provides only a fraction of the story. A multi-pronged approach is the only way to identify actionable patterns and solve recurring issues.

The biggest barrier to a high FCR isn't a lack of skill. It's a lack of immediate access to the right information or expertise at the exact moment it's needed most.

Combine these three methods to build a complete view of your operational weaknesses:

1. Analyze Service Logs for Patterns

Don’t just skim the “reason for visit” notes. Look for recurring themes across all failed first visits. Are repeat calls consistently linked to a specific type of machine, a particular fault code, or even certain technicians? This data will point you toward targeted training needs or gaps in your documentation.

2. Implement Post-Visit Customer Surveys

A brief, automated survey sent to customers after a service call delivers valuable, unfiltered feedback. Ask direct questions like, “Was your issue fully resolved during our first visit?” This measures FCR from the customer’s perspective—the one that truly dictates satisfaction and loyalty.

3. Conduct Technician Interviews

Your field team has firsthand knowledge of operational challenges. Create a safe, open environment for them to share their difficulties without fear of blame. Inquire about the biggest time-sinks on a job site, moments they felt unprepared, or instances where they needed better access to information.

By systematically gathering and analyzing this data, you can move from assumption to informed action. This diagnostic phase is critical. It lays the groundwork for creating effective training, deploying the right support technology, and building robust problem-solving strategies that will tangibly improve your FCR. For a deeper dive, check out our guide on maintenance problem-solving.

Build a High-Performance Team with Immersive Training

Technician competence is the foundation of a high First Call Resolution rate. A confident, well-prepared technician is your most valuable asset against costly and frustrating repeat visits.

However, traditional training methods often fail to bridge the gap between the classroom and the field. Reading manuals or viewing presentations does not replicate the pressure of troubleshooting live equipment with a client present.

This is where many FCR initiatives fall short. Technicians may understand the theory but lack the hands-on muscle memory to apply it under pressure. Modern, immersive training technologies are specifically designed to solve this challenge.

Moving Beyond the Classroom with Virtual Reality

Virtual Reality (VR) training immerses technicians in active, hands-on learning. Instead of just reading about a complex repair, they can perform it step-by-step in a completely safe, controlled virtual environment.

VR solutions can create interactive, one-to-one digital twins of your actual equipment. This allows a new hire to practice a difficult pump replacement or a precise sensor calibration dozens of times before ever touching the physical asset.

This approach delivers tangible advantages for building a team that achieves first-time fixes:

- Practice Without Penalty: Trainees can make mistakes without causing equipment damage, production downtime, or safety risks. This freedom to learn from errors is critical for building deep competence.

- Repetition Breeds Mastery: Technicians can run through complex procedures until the process becomes second nature, giving them the speed and accuracy needed in the field.

- Exposure to the Unexpected: You can simulate rare but critical equipment failures that a technician might otherwise not encounter for years, ensuring they are prepared for any situation.

This type of simulated, hands-on experience translates directly to better on-site performance. When a technician arrives at a job, the situation feels familiar because they have already addressed it in a virtual setting.

The goal of modern training isn't just to transfer knowledge; it's to build unshakable confidence. A technician who has successfully completed a repair ten times in a VR simulation will approach the real thing with a level of certainty that directly contributes to a first-call fix.

Industry data shows that while the global FCR benchmark is around 80%, many teams are stuck in the 70-79% range, where 20-30% of all issues require a second visit. Studies have shown that VR training can accelerate skill acquisition by up to 75% while reducing material waste, ensuring technicians can solve complex problems on the first visit.

What This Means for Field Performance

The impact of immersive training extends far beyond the training room. A team sharpened with VR simulations becomes a more adaptable and effective field service unit.

For example, when introducing a new, highly specialized piece of machinery, instead of the logistical challenge of centralizing training, you can deploy a VR module. Technicians can train at their local sites, reducing travel costs and operational downtime.

When the first service call for that new machine comes in, the responding technician is already familiar with its layout, common fault points, and specific repair protocols. This preparation is precisely how to improve first call resolution and enhance customer satisfaction.

You can dive deeper into this methodology in our guide on what immersive learning is.

Creating a Culture of Continuous Learning

Immersive training also helps build a culture of continuous skill development. VR modules can be updated as equipment changes or new procedures are introduced, keeping your team’s knowledge base current.

This adaptable approach ensures your workforce keeps pace with technological advancements. Your technicians are not just prepared for today's challenges; they are equipped to handle the machinery of tomorrow. By investing in this forward-thinking training, you build a high-performance team that views every service call as an opportunity to succeed on the first try.

Bring Your Top Expert to Every Single Job with AR

Even the best-trained technicians will eventually encounter an issue they cannot solve alone—an unfamiliar piece of equipment, a bizarre intermittent fault, or a problem not covered in any manual. This is the critical moment where a first-time fix can quickly devolve into a frustrating callback.

The traditional method for handling this involves phone calls, low-quality photos, and significant guesswork, often ending with the need to dispatch a senior technician.

Augmented Reality (AR) remote assistance offers a modern solution. It allows you to virtually place your most seasoned expert on-site, seeing exactly what the field technician sees. This technology closes the gap between uncertainty and a decisive, expert-guided resolution.

AR creates a live, "see-what-I-see" link between the on-site technician and a remote expert. Using smart glasses or a tablet, the field technician shares their real-time point of view, and the expert is virtually present to guide them.

Closing the Knowledge Gap in Real Time

This immediate visual connection is a significant advancement for achieving a first-time fix. The remote expert is not just listening to a verbal description; they are seeing the problem firsthand and can spot subtle clues a less experienced technician might miss.

It eliminates guesswork in complex repairs. The expert can walk the technician through the correct diagnostic steps, ensuring nothing is overlooked. This direct collaboration can turn a potential repeat visit into a successful first-time resolution.

Furthermore, it distributes your top-tier expertise across the entire team. A junior technician with an AR tool has an instant connection to your most senior personnel. This capability dramatically boosts the effectiveness of your entire crew and is a powerful strategy for how to improve first call resolution. The expert can use digital annotations to draw on the technician’s screen, highlight the exact component to check, or overlay a schematic directly onto the real-world equipment.

From a Good Idea to a Real-World Fix

Consider this practical use case: a technician is working on a complex piece of manufacturing machinery and is stumped by a fault not documented in the service manual. Instead of scheduling a specialist, they initiate an AR support call.

The remote expert, viewing through the technician's camera, immediately notices a faint flicker on an indicator light that the on-site technician had overlooked. Using AR annotations, the expert circles the correct diagnostic port on the tech's screen and overlays the exact sequence of tests to run.

Within minutes, they identify the root cause: a faulty sensor, a part the technician has in their vehicle.

Without AR, this scenario would likely end with a second truck roll, a frustrated customer, and extended machine downtime. With AR, the problem is diagnosed and fixed in one visit, saving money, boosting productivity, and reinforcing customer confidence.

This technology delivers measurable results. Industry KPI benchmarks for technical support show an average FCR of 70-79%, with world-class performance at 80% or higher. Remote support tools help teams achieve these elite numbers by reducing expert travel by up to 75% and cutting service times in half.

Traditional Support vs AR-Assisted Support

The following comparison illustrates the clear advantages of an AR-assisted approach over traditional methods.

| Metric | Traditional Support (Phone/Video Call) | AR-Assisted Support |

|---|---|---|

| Diagnostic Accuracy | Low to moderate; relies on verbal description and static images. | High; expert sees the live environment and can guide diagnostics. |

| Resolution Time | Long; involves significant back-and-forth communication. | Short; real-time guidance and visual instructions accelerate the fix. |

| Likelihood of FCR | Moderate; high chance of misdiagnosis or needing a specialist. | Very high; expert knowledge is applied directly to the problem. |

| Technician Confidence | Varies; junior techs may struggle with complex issues. | High; technicians feel supported and empowered to tackle any job. |

As the table shows, AR is a transformative technology that fundamentally improves the service call dynamic.

Effective implementation of this technology relies on a stable connection, which can be a challenge in large plants or remote sites. Understanding solutions like a Distributed Antenna System is critical for ensuring reliable mobile signal strength.

Equipping your team with AR-powered support is a strategic move that changes how expertise is shared. You can learn more by exploring our guide on augmented reality remote assistance. It makes your best people more effective, upskills your entire workforce, and establishes first-call resolution as the new standard.

Creating a Continuous Improvement Cycle for FCR

Deploying new training and technology is a significant step, but it is not the final one. Achieving a world-class First Call Resolution rate is not a one-time project; it is a continuous process.

You must build a sustainable cycle fueled by data, feedback, and a commitment to learning from every service call. Lasting success comes from a culture of constant operational refinement. This means analyzing what happened on-site to identify hidden problems and make incremental adjustments that lead to substantial improvements.

Establish Your Baseline with Accurate Measurement

Before you can improve, you must know your starting point. Relying on a technician's self-reported "resolved" status often provides an overly optimistic picture. To get a true measure of your FCR, you need to incorporate the customer's perspective and track system data.

A two-part approach is highly effective:

- Post-Service Surveys: Within 24 hours of a visit, send a simple, automated SMS or email to the customer asking a direct question like, "Was your issue fully resolved during our technician's visit?" This provides direct, unfiltered feedback.

- Re-Open Rate Tracking: Monitor your ticketing system for how many tickets are re-opened or how many new tickets are created for the same asset within a set timeframe, such as 7-14 days. This helps identify fixes that were not permanent.

Combining these two data points gives you a much more reliable FCR baseline and highlights any discrepancies between a technician's assessment and the customer's actual experience.

Create Robust Technician Feedback Loops

Your technicians are your most valuable source of on-the-ground intelligence. They know which processes are inefficient, what documentation is missing, and where they consistently encounter obstacles.

It is essential to establish a formal system to capture their feedback. This could involve regular debriefing sessions or a simple digital channel for reporting challenges without blame. The goal is to collect insights on real-world obstacles, which is invaluable for refining your knowledge base and planning future training modules.

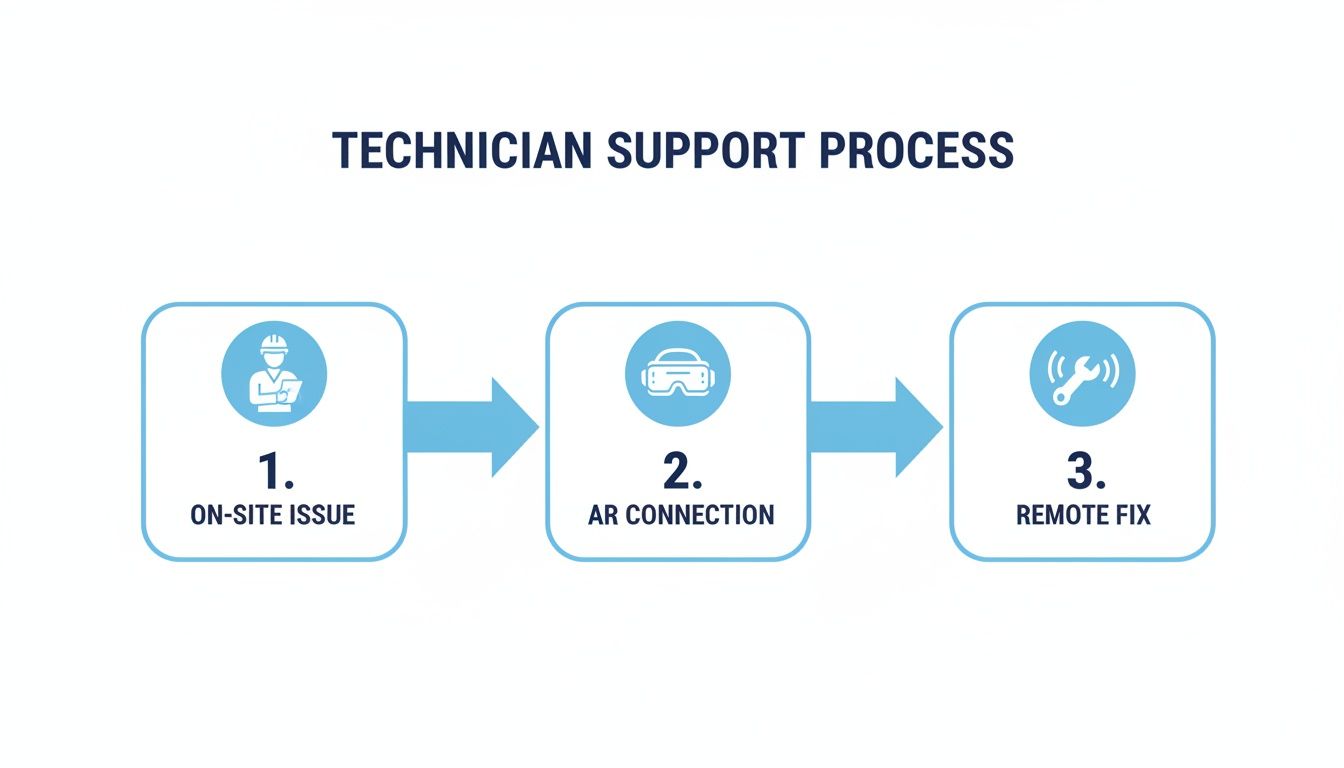

The right tech support process can turn a potential repeat visit into a successful first call, bridging the gap between a problem and its resolution.

This process shows just how technology can empower a technician on-site, connecting them with an expert who can guide them to a remote fix.

Use Data Analytics to Identify Problem Trends

Once you have accurate FCR data and consistent technician feedback, you can begin to identify patterns. Analyze your service data to find correlations. Are repeat visits consistently linked to a specific piece of equipment, a particular error code, or even a certain geographic region?

A single failed fix is an anecdote. A pattern of failed fixes for the same reason is an opportunity. Use your data to turn recurring problems into targeted improvement initiatives.

For example, if you discover that 30% of all callbacks are related to one specific machine model, you have a clear action item. This insight can drive several improvements:

- Update the Knowledge Base: Add detailed troubleshooting guides, video walkthroughs, and schematics specific to that model.

- Refine Training: Build a new VR training module that simulates the most common failures on that exact machine.

- Proactive Alerts: Equip your remote experts with data on this trend so they can provide faster, more accurate support when a relevant call comes in.

This data-driven approach ensures you are making strategic decisions based on hard evidence, not guesswork, on how to improve first call resolution. Incorporating strategies like improving First Contact Resolution rates with smart routing solutions can also enhance this cycle by ensuring the right technician is dispatched from the start. This continuous loop—measure, gather feedback, analyze, and act—is what transforms a good service operation into a great one.

Got Questions About FCR? We've Got Answers.

Even with a well-defined strategy, encountering questions and roadblocks is a natural part of the improvement process. Addressing these common concerns is often key to moving forward with confidence and building a more effective operation.

Let's address some of the most pressing questions we hear from field service leaders about boosting FCR.

What Is a Good First Call Resolution Rate for An Industrial Team?

While the global average FCR rate is around 62%, this figure is not highly relevant for industrial and technical teams where the stakes are much higher. Every repeat visit is costly, and equipment downtime can be catastrophic for a client's business.

Industry benchmarks suggest a good FCR rate is between 70-79%. To be considered world-class, you should aim for 80% or higher. For highly specialized fields like precision manufacturing, achieving 75-85% is a challenging but realistic goal. The key is to benchmark against your specific sector rather than a global average. Even a one-percent gain can lead to significant operational savings and improved customer satisfaction.

The right FCR target isn't a universal number from a report. It's a strategic goal that reflects your industry's complexity and your customers' expectations. Aim for top-tier performance by continuously refining processes and equipping your technicians with the tools they need to succeed.

How Do I Accurately Measure FCR?

This is a critical and common challenge. Simply allowing technicians to mark a ticket as "resolved" can lead to inflated numbers that do not reflect reality. A technician might fix an immediate symptom, but if the root cause leads to another failure a week later, the first visit was not a success.

To get an accurate view of your FCR, you need to analyze it from multiple angles:

- Incorporate the Customer's Voice: Use simple, automated post-service surveys via SMS or email. A direct question like, "Was your issue fully resolved in one visit?" provides the ultimate source of truth.

- Monitor Re-Opened Tickets: Your system data is a valuable resource. Track tickets that are "re-opened" or new tickets logged for the same asset within 7 to 14 days. This is a clear indicator of a failed first-time fix.

- Identify Repeat Call Drivers: Analyze your data to spot the patterns behind repeat calls. This will uncover issues that self-reported data might miss.

Combining direct customer feedback with hard system data provides a much more honest picture of your true FCR performance, allowing you to focus your improvement efforts where they will have the greatest impact.

Will Implementing AR and VR Solutions Disrupt My Operations?

The prospect of implementing new technologies like Augmented and Virtual Reality can seem daunting. However, modern solutions are designed to integrate into your existing workflow, not disrupt it.

Many of these platforms are offered as Software-as-a-Service (SaaS), minimizing upfront costs and simplifying deployment. A phased approach is generally the most effective strategy.

- Start Small with a Pilot: Select one team or a single, common problem to test the technology. This allows you to prove the ROI and resolve any issues on a small scale.

- Think Augmentation, Not Replacement: These tools are designed to enhance your existing processes. AR remote assistance, for example, digitizes and improves the existing practice of calling an expert for help.

- Measure Everything: Track key metrics from your pilot program. When you can demonstrate tangible benefits like a 75% reduction in expert travel or a 50% decrease in average service times, the business case for a wider rollout becomes compelling.

The goal is not disruption; it is empowerment. When approached strategically, AR and VR become powerful tools that make your team's job easier and your operation more efficient.

Ready to transform your team's performance and achieve world-class First Call Resolution rates? AIDAR Solutions provides the immersive AR and VR tools that empower your technicians with the skills and real-time support they need to solve any problem on the first visit. Discover how our solutions can reduce your operational costs and boost customer satisfaction by visiting https://aidarsolutions.com.