Augmented Reality in Warehouses: A Practical Guide to Boosting Efficiency

Warehouse managers face a daily reality of rising customer demands, labor shortages, and the high cost of simple mistakes. The concept of augmented reality in warehouses is no longer a futuristic vision—it's a practical, here-and-now solution that tackles these intense operational pressures head-on by layering critical digital information onto an employee's view of the physical world.

The Reality of Modern Warehousing Pressures

Today’s warehouses are stretched thin. The pressure to fulfill orders faster and with flawless accuracy has never been greater. Simultaneously, many operations are contending with a shrinking labor pool and the persistent problem of human error.

Traditional methods are struggling to keep pace. Paper lists and even handheld scanners, once the standard, now create bottlenecks. They slow down new hire training and are a direct cause of costly mistakes in picking, packing, and inventory management. Every mis-picked item or misplaced pallet erodes profit margins and, just as importantly, customer trust.

Bridging the Gap with AR Technology

This is precisely where augmented reality (AR) technology provides a tangible strategic advantage. Imagine warehouse associates wearing smart glasses that display vital information directly in their line of sight. Instead of constantly looking down at a scanner or a clipboard, they see digital instructions guiding their every move, hands-free.

This technology forges a direct, real-time link between your digital backbone—such as your Warehouse Management System (WMS)—and your frontline workers. It effortlessly transforms complex, multi-step tasks into simple, visual workflows.

By presenting information exactly where it's needed—showing the optimal path, the precise item to grab, and its destination—AR dramatically reduces the cognitive load on your team. The result is faster, more accurate work with significantly less training time.

How AR Delivers Real-World Value

The core purpose of augmented reality in warehouses is to enhance human capabilities, not replace them. It provides clear, intuitive, hands-free guidance that directly addresses the most common operational challenges. For managers focused on how to reduce operational costs, AR offers a direct path to targeting and resolving key inefficiencies.

- Visual Navigation: AR can project arrows and highlighted pathways directly onto the warehouse floor, guiding workers along the most efficient route to their next pick, eliminating wasted steps and confusion.

- Item Highlighting: Upon arrival at a location, the correct bin or specific item is digitally outlined, confirming the selection instantly and virtually eliminating picking errors.

- Real-Time Information: Order details, quantities, and put-away instructions appear in the user's field of view. There's no need to stop and consult a separate device, allowing for continuous momentum throughout a shift.

This approach effectively turns your physical warehouse into an interactive, data-rich environment, giving your team the tools they need to meet today's relentless demands.

How AR Gets to Work on the Warehouse Floor

Let’s move from theory to practical application. Augmented reality completely re-engineers how daily warehouse tasks are performed. It's about injecting digital precision into physical workflows, turning routine jobs into guided, efficient experiences. This isn't just about innovative technology; it's about providing your workforce with the exact information they need, right when they need it, completely hands-free.

The adoption of augmented reality in warehouses is accelerating. Shipments of AR devices are expected to climb to 43.2 million by 2025, a significant increase reflecting a compound annual growth rate of 53.1% since 2020. This growth is driven by AR's ability to offer proven solutions to persistent problems like picking bottlenecks and high error rates.

Revolutionizing Order Picking

Order picking is consistently the most labor-intensive and error-prone component of warehouse operations. Traditionally, workers have juggled paper lists or handheld scanners, forcing them to constantly switch focus between a device, the aisle, and the item itself. This back-and-forth slows them down and creates numerous opportunities for mistakes.

AR technology fundamentally changes this dynamic. Consider a worker wearing smart glasses who sees picking instructions overlaid directly in their line of sight.

- Before AR: The picker consults a scanner, identifies aisle G, walks the aisle searching for bay 14, locates bin 3, scans the bin, checks the screen to confirm the item, picks it, and then confirms the pick on the scanner. This multi-step process is inefficient.

- After AR: A digital arrow appears on the floor in the smart glasses, guiding the picker directly to aisle G, bay 14, bin 3. Once there, a virtual box highlights the correct bin while an overlay displays the item image and quantity. A quick scan with the glasses’ built-in scanner confirms the pick automatically, and the system immediately guides them to the next item.

This “vision picking” method is not just faster—it's nearly foolproof, effectively elevating every employee to the level of your most accurate picker.

The true advantage lies in eliminating guesswork. By delivering information visually and in context, AR frees up your team to focus entirely on the physical task of picking, resulting in a significant boost to both speed and accuracy.

Perfecting Put-Away and Slotting

Receiving items is only half the battle; correct put-away is equally critical. A single item stored in the wrong location can lead to lost product, wasted search time, and inaccurate inventory counts. AR acts as a powerful safeguard against these costly mistakes.

When an associate is ready to shelve new inventory, their AR glasses can direct them to the optimal slot based on your WMS rules—factoring in variables like velocity, size, and weight. As they approach the location, the glasses can scan both the bin and product barcodes simultaneously, providing an instant visual cue: a green check for a match or a red 'X' for an error. This simple verification ensures inventory is always where it should be, maximizing space utilization and maintaining data accuracy from the start.

Accelerating Inventory Management

Cycle counts and full inventory audits are necessary but often disruptive. They are essential for accuracy but frequently bring operations to a halt while teams manually scan and count items. With AR, this process becomes significantly faster and less disruptive.

An employee equipped with AR glasses can simply walk the aisles while their device automatically scans barcodes within their field of view. The system can highlight items that need counting and display the expected quantity versus the actual count in real time. This enables rapid verification without the need to handle a separate scanner, making it practical to conduct more frequent spot-checks without shutting down entire sections of your warehouse. For anyone focused on optimizing inventory management, AR is an invaluable tool.

Immersive Training and Onboarding

Onboarding new hires to full productivity is a common challenge. Traditional training methods, combining classroom sessions with shadowing experienced staff, can take weeks. AR transforms this process into an immersive, on-the-job training experience from day one.

A new employee can be guided through a complex pick path or packing procedure with step-by-step visual instructions appearing directly before their eyes. This functions as a digital expert providing real-time guidance for every move. This approach not only reduces the learning curve from weeks to days but also builds confidence and ensures adherence to standard operating procedures from the outset.

Enabling Expert Remote Maintenance

Equipment downtime can halt warehouse operations instantly. When a critical piece of machinery like a conveyor system fails, operations are often stalled while waiting for a specialized technician to arrive on-site.

AR closes this gap through remote assistance. An on-site technician can wear smart glasses and stream their exact point-of-view to an expert located anywhere in the world. That expert can then annotate the technician's live video feed with drawings, diagrams, and instructions, guiding them through the repair as if they were physically present. This capability slashes downtime, reduces travel costs, and empowers your internal team to resolve more complex problems. It's one of many powerful augmented reality industrial applications demonstrating how this technology's impact extends far beyond the warehouse floor.

Measuring the Real-World Impact of AR

Adopting new technology is about delivering tangible results that positively impact the bottom line. When it comes to augmented reality in warehouses, the impact is measurable against the key metrics that define operational success.

The true value of AR becomes clear when it is connected to concrete improvements in efficiency, accuracy, and cost savings. These are not minor adjustments. Even small gains in core processes like order picking or new hire training compound quickly, leading to significant financial returns and a more resilient supply chain.

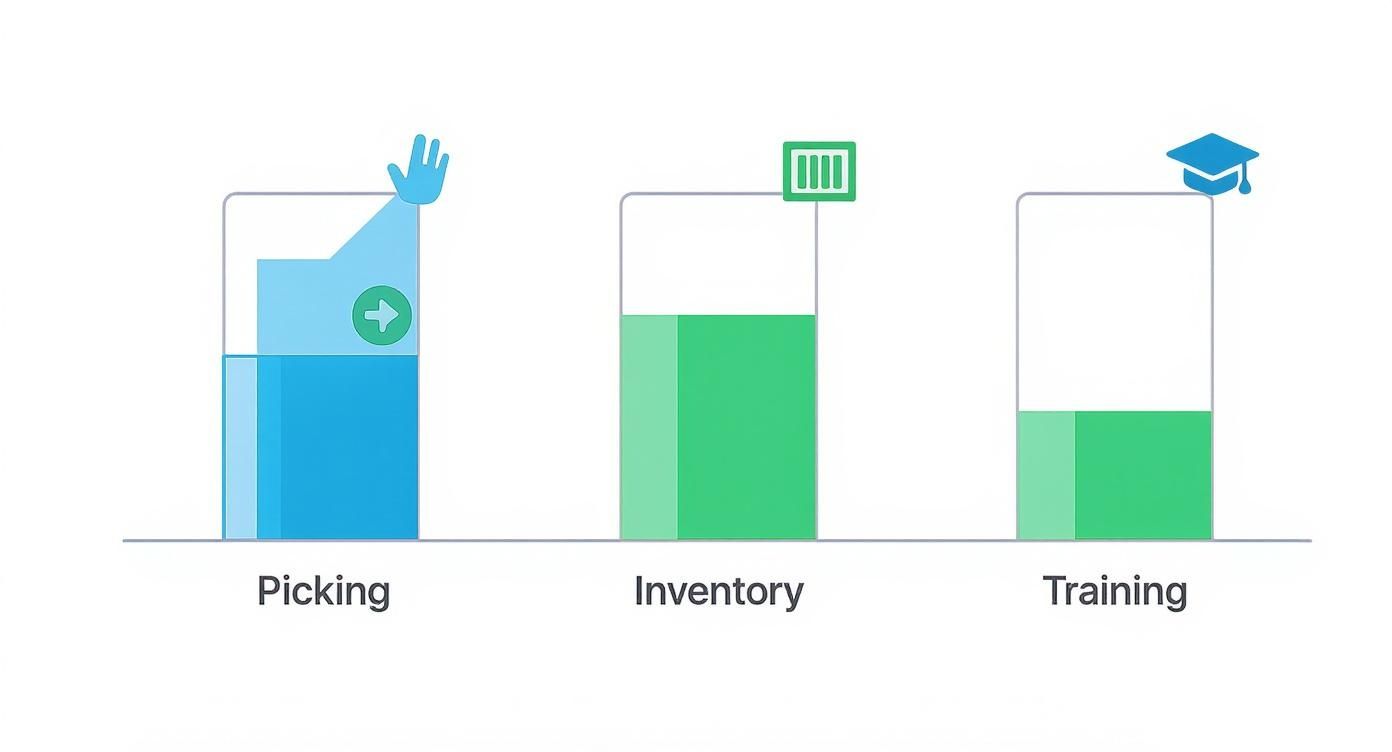

This infographic breaks down how much AR can improve performance in three critical warehouse functions:

As shown, the improvements are substantial across the board. AR-driven guidance directly boosts performance in the essential, everyday tasks that keep an operation running.

Boosting Productivity and Accuracy

Order fulfillment is where the most immediate and dramatic impact is often seen. Traditional picking methods are fraught with friction points. Workers constantly divide their attention between handheld scanners, pick lists, aisle signs, and the items themselves. This continuous context-switching slows them down and increases the likelihood of costly errors.

AR eliminates this friction. By displaying clear, visual cues directly in an employee's line of sight, the system guides them along the most efficient pick path and highlights the correct item on the shelf. This hands-free, heads-up approach allows workers to focus completely on the task at hand.

The result is a powerful combination: workers fulfill more orders in less time, and they do so with near-perfect accuracy. Every mis-pick eliminated translates into direct savings on returns, reverse logistics, and customer service resources.

Real-world applications have demonstrated these benefits. For example, AR inspection tools have been shown to slash error rates by 25% during quality control checks. In core picking operations, AR overlays have driven up to a 20% improvement in picking accuracy—a significant advancement for any warehouse.

To understand how these improvements translate to financial and operational gains, it is crucial to establish a baseline and measure against it. The table below illustrates the kind of shift that can be expected.

Warehouse KPI Improvements with AR Technology

| Key Performance Indicator (KPI) | Traditional Warehouse Benchmark | AR-Enhanced Warehouse Performance | Impact |

|---|---|---|---|

| Picking Accuracy | 99.0% – 99.5% | 99.9%+ | Drastically reduces costly shipping errors and returns. |

| Picks Per Hour (PPH) | Varies by facility | 15-35% Increase | Boosts overall throughput without increasing headcount. |

| New Hire Training Time | 2-4 weeks to full productivity | 2-3 days | Slashes onboarding costs and gets new staff contributing faster. |

| Safety Incidents | Industry average rates | 10-20% Reduction | "Heads-up" guidance improves situational awareness, preventing collisions. |

| Inventory Count Time | Days or weeks | Up to 50% Faster | Speeds up cycle counts and wall-to-wall inventories, reducing downtime. |

These metrics show a clear pattern: AR doesn't just make incremental adjustments; it fundamentally raises the performance ceiling for the entire operation.

Accelerating Onboarding and Training

Getting new hires up to speed is one of the largest hidden costs in any warehouse. A conventional training process can take weeks, preventing new employees from being fully productive while diverting experienced staff to act as mentors.

Augmented reality completely changes this model. It turns training into a guided, on-the-job experience from day one.

- From Weeks to Days: A new hire can put on a pair of smart glasses and immediately receive real-time, step-by-step instructions for picking, packing, or put-away.

- Reduced Cognitive Load: The visual, intuitive nature of AR guidance simplifies complex processes, lowering the stress and uncertainty associated with a new role.

- Standardized Procedures: AR ensures every employee is trained to follow the exact same best practices, driving consistency and quality across the entire operation.

This accelerated learning curve means your team becomes productive almost immediately, cutting training-related costs and allowing veteran staff to return to their core responsibilities.

Creating a Safer Work Environment

A guided workforce is a safer workforce. AR contributes directly to warehouse safety by keeping workers' eyes up and aware of their surroundings, rather than focused on handheld devices, which are a common cause of collisions with forklifts, racking, or other personnel.

By putting navigation cues and task information into a heads-up display, AR helps employees maintain constant situational awareness. It's even possible to program alerts for potential hazards—like forklift traffic or restricted areas—to appear directly in their field of view. This proactive approach to safety not only prevents accidents but also builds a culture of awareness. Knowing which operational efficiency metrics to track is key to substantiating these safety improvements with data.

A Practical Roadmap for AR Implementation

Understanding AR's potential value is one thing; successfully implementing it on your warehouse floor is another.

The key is not a massive, overnight overhaul, but a methodical, phased approach that proves the concept, builds momentum, and avoids disrupting your entire operation. The goal is to start smart and scale successfully.

It begins with a thorough analysis of your current operations. Where are the biggest challenges? Are picking errors driving up costs? Is new hire ramp-up time too long? Are inventory inaccuracies a constant problem? Pinpointing the area with the most to gain provides a clear target for a pilot program that will deliver the biggest impact.

Phase 1: Laying the Foundation

Before unboxing any new hardware, a solid plan is essential. This first phase is about defining success and ensuring your technical environment is ready for augmented reality in warehouses. Without this groundwork, even the best technology will not perform optimally.

Start by setting clear, measurable objectives for your pilot. Go beyond general goals like "improving efficiency" and define specific KPIs to track, such as:

- Increasing picks per hour by 15%.

- Reducing picking errors to less than 0.1%.

- Cutting new hire training time from three weeks to three days.

With clear goals, you can select the right tools. This includes choosing AR hardware—like smart glasses—that is rugged enough for the warehouse environment and has a battery that lasts a full shift. Concurrently, you must assess your facility's Wi-Fi. A stable, low-latency connection is non-negotiable for AR devices that require real-time communication with your WMS.

Phase 2: The Pilot Program

This is where theory becomes practice. The key is to keep the scope small and focused. Select one specific area of your warehouse—a single picking zone or a small team of operators—to test the AR solution. This controlled environment allows you to gather real data and feedback without risking your entire operation.

During the pilot, the focus is on execution and observation.

- Integration: Work closely with your AR partner and IT team to connect the AR software with your Warehouse Management System (WMS). Data must flow seamlessly in both directions.

- Training: Although AR is intuitive, provide the pilot group with a brief, hands-on training session. Allow them to become comfortable with the glasses and understand the on-screen visual cues.

- Feedback: This is the most critical step. Engage with your users on the floor. What is working well? What is clunky or confusing? Are the glasses comfortable? This direct feedback is invaluable for fine-tuning the workflow.

A pilot program is not just about proving the technology works. It's about proving it works for your people, in your facility. User adoption is the ultimate measure of success, and listening to your team early is the best way to achieve it.

When you measure your pilot data against the established KPIs, you will have the evidence needed to build a business case for a wider rollout. Comparing the AR-equipped team's performance to your baseline provides the hard numbers to justify the investment. For more on strategic operational planning, consult this guide on improving supply chain efficiency with a practical roadmap.

Phase 3: Scaling and Change Management

Once your pilot has proven its value, it's time to expand. This phase is as much about people as it is about technology. How you manage this transition will determine the long-term success of the project.

A smart change management strategy is essential. Begin by sharing the positive results from the pilot. Demonstrate how the technology made the pilot team’s jobs easier and more accurate. Identify your "AR champions"—enthusiastic users from the pilot group who can help train their colleagues and build excitement.

As you scale, avoid a simultaneous, facility-wide launch. Roll out the solution in phases, section by section. This allows your support team to focus their efforts and resolve any issues that arise. Understanding the fundamentals of an augmented reality workflow can help prepare your teams for this new way of working. Maintain clear communication, celebrate small wins, and provide ongoing support. This is how a technology project becomes a genuine operational victory.

Choosing the Right AR Technology Partner

Implementing augmented reality is not like purchasing a new piece of equipment. It is a strategic shift that depends on finding a true partner, not just a vendor. The right partnership distinguishes a stalled pilot project from a full-scale deployment that delivers real, lasting value.

This decision is more critical than ever, as the market for augmented reality in warehouses experiences rapid growth. It’s projected to reach $4.25 billion by 2025, an increase from $3.75 billion in 2024. This growth reflects the increasing reliance on AR in operations. Your choice of partner is a significant factor in your success. For a deeper dive, review the leading industry analysis on WiseGuyReports.com.

A true partner understands that hardware and software are just components of a larger operational puzzle. They should function as an extension of your team, providing the expertise to handle the complexities of integration, training, and long-term support.

Evaluating Expertise and Industry Focus

The first criterion should be experience in logistics and warehousing. A provider that understands your industry will speak your language. They will be familiar with the unique challenges of inventory management, order fulfillment, and the continuous drive to optimize workflows.

Look for a proven track record. They should be able to provide clear case studies and real-world examples of how they have delivered measurable results in warehouses similar to yours. Their expertise should extend beyond the technology itself to the practicalities of a busy and dynamic warehouse environment.

This ensures you receive a solution tailored to your specific goals, not a generic, one-size-fits-all product.

Assessing Technical Capabilities and Integration

Seamless integration is non-negotiable. Any potential partner must demonstrate the ability to connect their solution to your existing Warehouse Management System (WMS) and other core systems without causing disruptions.

A partner’s ability to integrate with major WMS platforms is a direct indicator of their technical maturity. It shows they’re committed to building a cohesive digital ecosystem, not just selling you another isolated tool.

Ask detailed questions about their integration process, API flexibility, and experience with systems like yours. A partner who can guarantee a smooth, real-time flow of data between their AR platform and your WMS is essential.

Do not focus solely on software. Evaluate their approach to hardware. A strong partner should be hardware-agnostic, guiding you to the best smart glasses or devices for your specific environment and use case, rather than promoting a single brand.

Prioritizing Comprehensive Support and Training

Finally, the long-term success of your AR initiative will depend on the support you receive after the initial sale. A top-tier partner offers a complete support structure covering everything from implementation and beyond.

- Implementation Support: This includes on-site assistance, system configuration, and project management to ensure a smooth launch.

- User Training: Effective technology is useless if your team cannot use it efficiently. The partner must provide intuitive, hands-on training that enables your staff to become comfortable and confident with the new tools quickly.

- Ongoing Technical Support: You need a responsive team available to troubleshoot issues promptly, minimizing downtime and keeping your operation moving.

Choosing a partner is a long-term commitment. By focusing on deep industry knowledge, proven integration capabilities, and a robust support framework, you can find a provider who will not only help you adopt AR but also enable you to thrive with it.

Your Next Steps Toward a Smarter Warehouse

The future of warehousing is not a distant concept; it is here and ready for implementation. Adopting augmented reality in your warehouse has evolved from a futuristic idea to a practical, accessible strategy for resolving today's operational challenges. This is a mature technology with a clear adoption path and a proven ability to deliver tangible returns.

AR directly addresses the critical areas of efficiency, accuracy, and safety, transforming your current team into a more productive and precise workforce. By eliminating guesswork and streamlining workflows, you can achieve the operational excellence goals that previously seemed out of reach.

Chart Your Course

The journey begins with a practical step: a thorough review of your own operations. Analyze your KPIs and pinpoint areas of friction. Are picking errors inflating costs? Is new hire training excessively long? Are inventory counts a constant source of frustration?

Pinpointing your single biggest pain point provides the perfect launchpad for a targeted pilot program. A successful pilot delivers the hard data and internal buy-in you need to make the case for a wider rollout.

This focused approach de-risks the investment and proves the value of AR in your specific environment, not just in theory.

Take Action Today

Once you have identified an opportunity, the next step is to explore how AR can be tailored to fit your unique challenges. It is crucial to connect with experts who understand both the technology and the intricacies of logistics to build a solid implementation plan.

A consultation can help you map out a pilot, define success metrics, and determine the integration requirements for your WMS. This proactive planning is what transforms the idea of a "smarter warehouse" into an actionable project. Consider reaching out to a solutions provider to explore how a customized AR solution could begin delivering value to your operation right away.

Got Questions About AR in the Warehouse?

Adopting any new technology raises valid questions. Understanding the practical aspects of implementing augmented reality—from financial returns to team adoption—is the first step toward making an informed decision. Here are direct answers to the most common questions.

What’s the Real ROI on an AR Project?

While exact figures will vary based on your operation's size and specific use case, most warehouses see a full return on their investment within 12 to 24 months. This payback comes from direct and tangible cost savings.

A significant portion of the ROI is derived from reducing picking errors. Each mistake can cost over $50 in reverse logistics, labor, and restocking. In addition, AR delivers a substantial productivity boost. A 15-20% increase in picking speed means more orders can be fulfilled with the same headcount, which positively impacts the bottom line and shortens the payback period.

The business case for AR is built on compounding efficiencies. You spend less on training, make fewer costly mistakes, and fulfill orders faster. This combination adds up to a powerful, measurable return that is realized quickly.

How Hard Is It to Connect AR to Our WMS?

This is a common concern, but modern AR solutions are designed for seamless integration with existing systems. A professional-grade AR platform must communicate with your Warehouse Management System (WMS)—this is a non-negotiable requirement.

Leading providers offer flexible APIs and pre-built connectors for major platforms like SAP, Oracle, and Manhattan Associates. A competent implementation partner will work closely with your IT team to ensure data flows smoothly in both directions. The goal is simple: the AR device receives real-time instructions from the WMS, and upon task completion, that information is sent back, eliminating manual data entry and delays.

What Kind of Training Will My Team Need?

This is one of the most significant advantages of AR. The system is designed to be so intuitive that it nearly eliminates the learning curve. The on-screen visual instructions are designed for immediate comprehension with minimal formal training.

Most team members will become comfortable with the technology within a single shift. Training typically consists of a brief overview covering three key areas:

- How to wear the device comfortably.

- How to interpret the on-screen guides and prompts.

- How to use simple voice commands or button presses, if required by the task.

Compared to the weeks it can take to train an employee on traditional scanners and paper-based systems, the speed of AR onboarding is a game-changer. New hires can be productive, accurate, and confident from day one.

Ready to see how AR can solve your specific operational challenges? The experts at AIDAR Solutions can provide a customized consultation and help you build a business case for your warehouse. Explore our solutions and book a demo today!